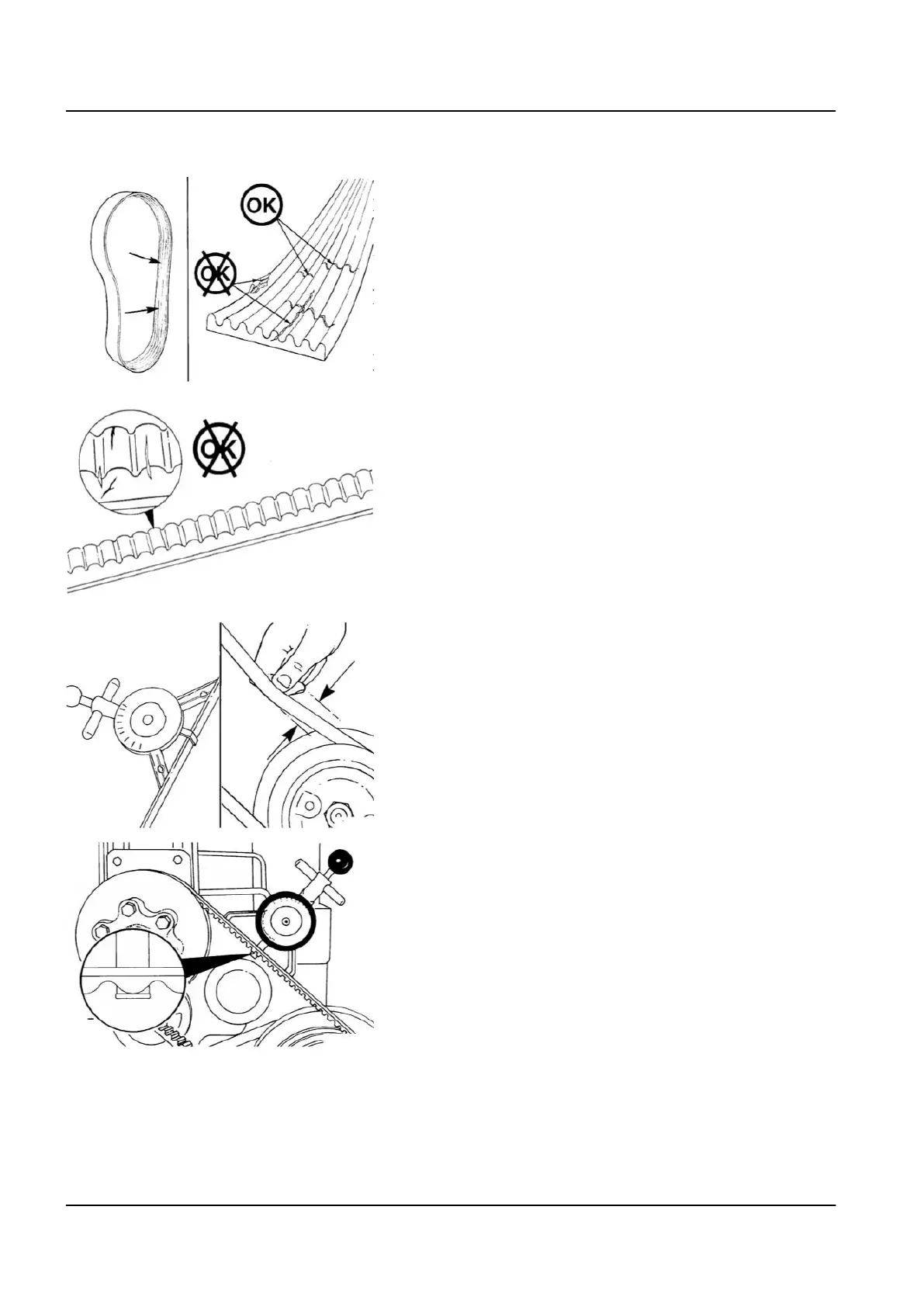

Examine drive belts

1 Inspect the drive belt for damage.

Transverse (across the belt) cracks are acceptable.

Longitudinal (direction of belt ribs) cracks that intersect with

transverse cracks are not acceptable.

2 If the belt is frayed, punctured, or material is missing, the belt

is unacceptable for reuse and must be replaced.

Belt damage can be caused by:

•

Incorrect tension

•

Incorrect size or length

•

Pulley misalignment

•

Incorrect installation

•

Severe operating environment

•

Oil or grease on the side of the belts.

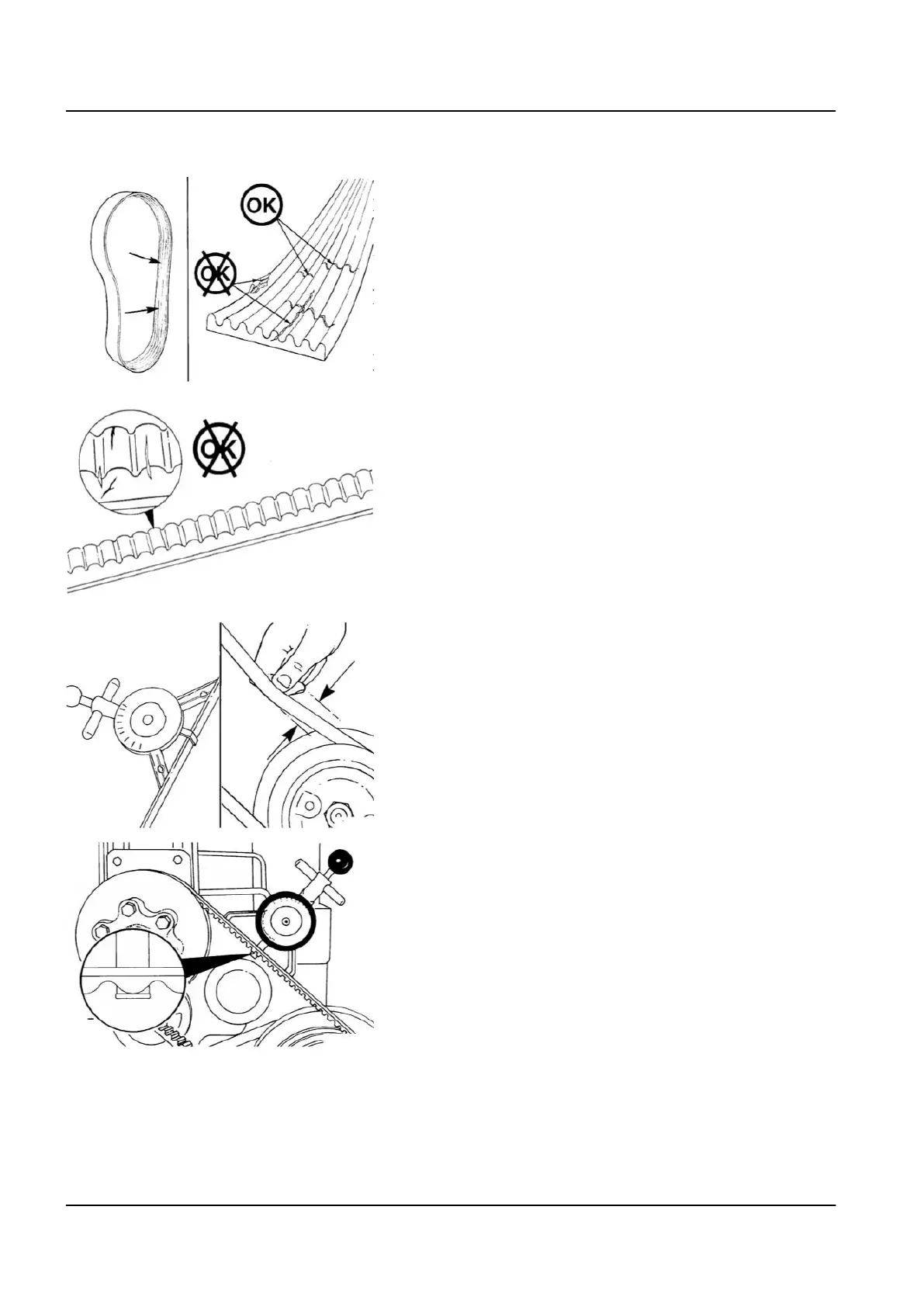

3 Measure the belt tension in the center span of the pulleys.

An alternate method (deflection method) can be used to

check belt tension by applying 110 N (25 lbf) force between

the pulleys on v-belts. If the deflection is more than one belt

thickness per foot of pulley center distance, the belt tension

must be adjusted.

4 For cogged belts, make sure that the belt tension gauge is

positioned so that the center tensioning leg is placed directly

over the high point (hump) of a cog. Other positioning will

result in incorrect measurement.

6 1 Engine – 1.5 Mechanical components of the engine

TL2 Maintenance Manual

591 003 Default

Loading...

Loading...