Fill

CAUTION

The system must be filled properly to prevent air locks or serious

engine damage can result. During filling, air must be vented from

the engine coolant passages. Wait 2 to 3 minutes to allow air to be

vented; then add mixture to bring the level to the top.

Make sure air is vented during the fill process:

•

Some thermostats have check balls that allow air to vent

through the thermostat when the thermostat is closed.

•

An air vent port connection, which connects to the top tank/

coolant recovery tank of the cooling system, is located next to

the water outlet.

The system has a design maximum fill rate of up to 19 liters (5 gal)

per minute.

NOTE

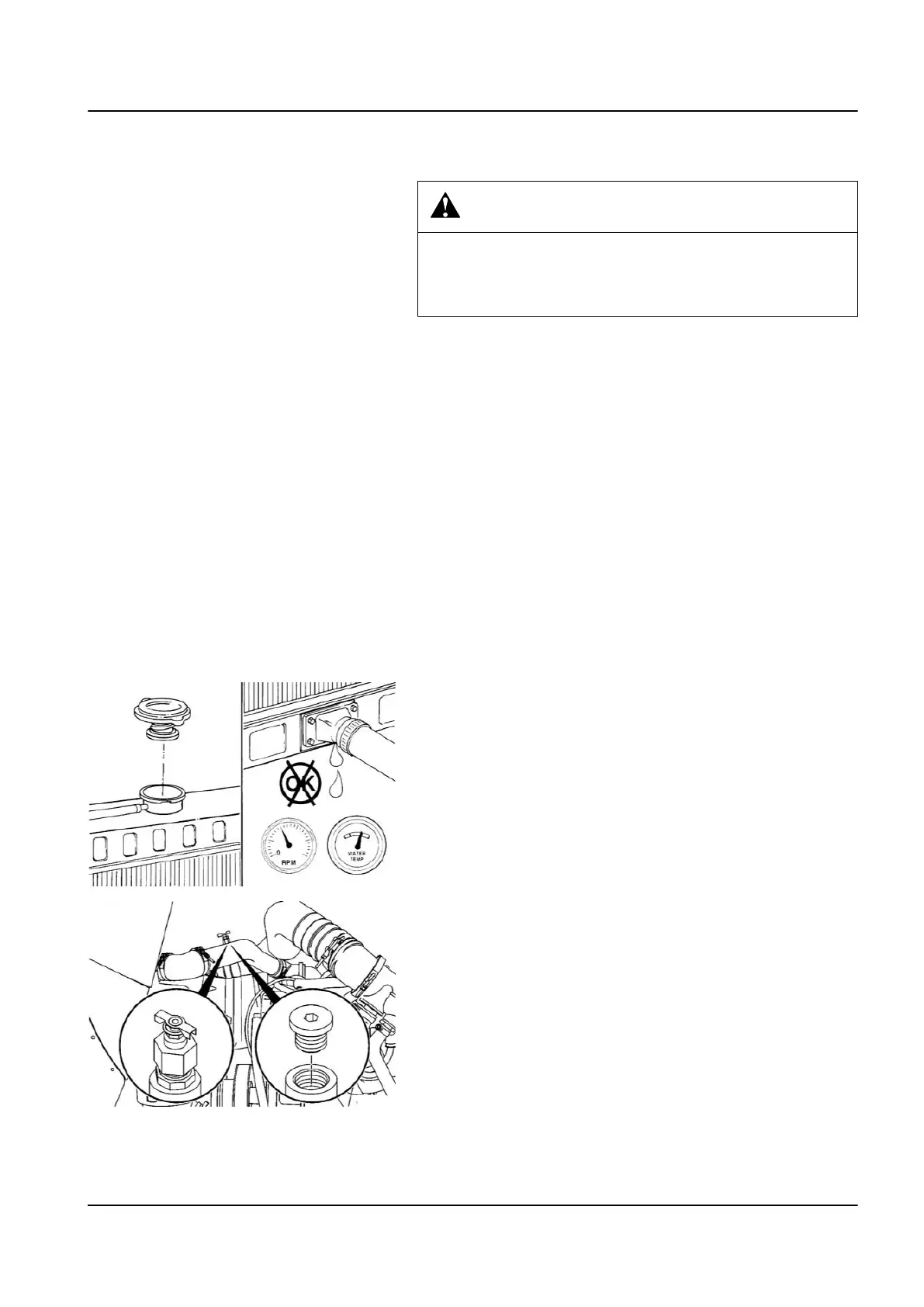

Some applications may be equipped with a manual bleed valve which

is to be opened to make sure of a proper fill. The upper radiator pipe

is a common location for bleed valves. The illustration is for reference

only.

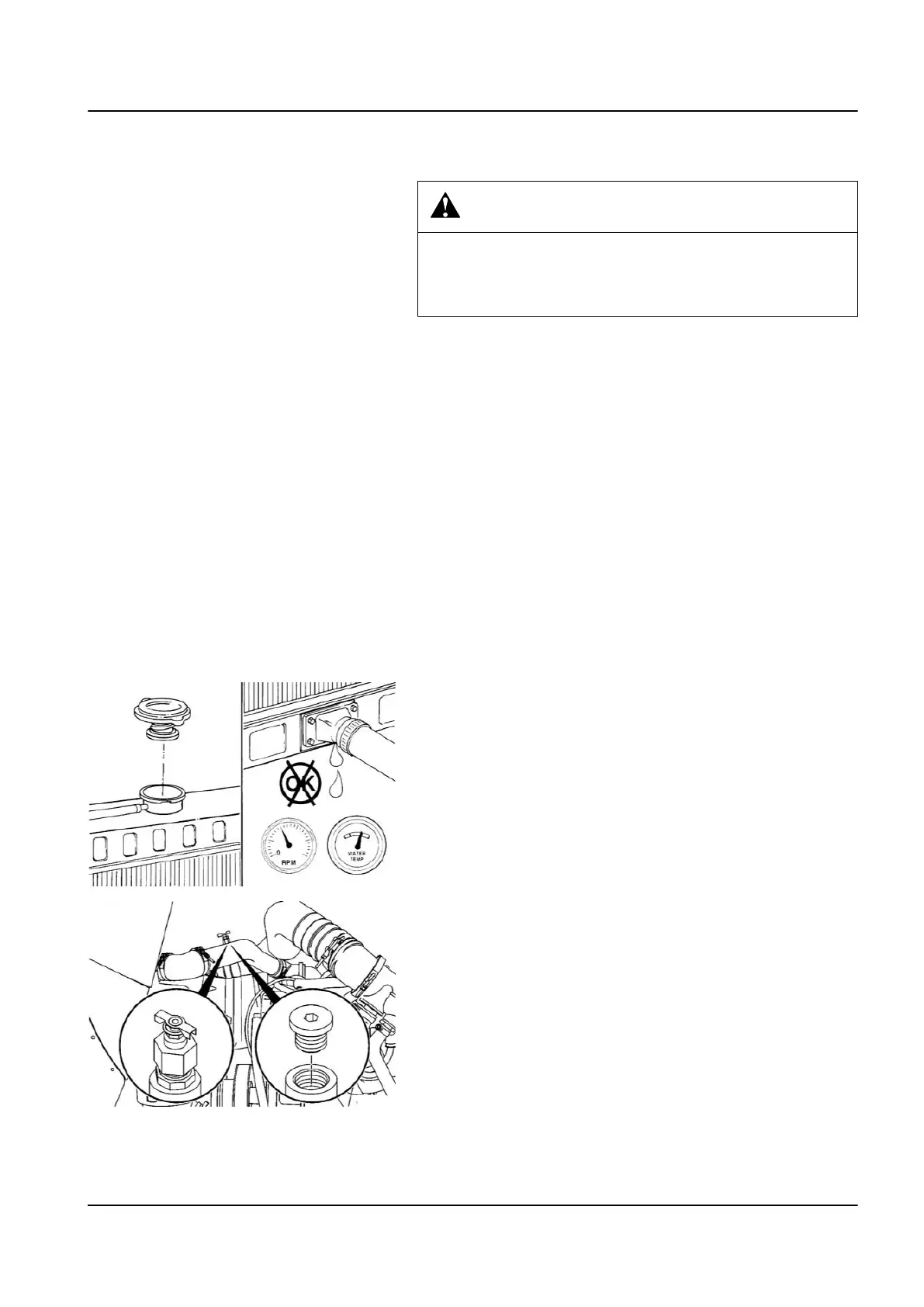

1 Remove the cooling system fill cap.

2 Fill the cooling system to the capacity or level stated in the

equipment manufacturer service information, using a mixture

of 50 percent water and 50 percent ethylene glycol or propy‐

lene glycol antifreeze.

NOTE

Some applications may be equipped with a manual bleed valve

which is to be opened to make sure of a proper fill. The upper radia‐

tor pipe is a common location for bleed valves. The illustration is for

reference only.

If applicable, open the manual bleed valve before filling the cooling

system.

Once properly filled, make sure to close the manual bleed valve.

1 Engine – 1.7 Cooling system 27

TL2 Maintenance Manual

591 003 Default

Loading...

Loading...