1312

TOWING AND

LONG-TERM STORAGE

TOWING

Failure to follow these instructions exactly can cause hitch ball failure or loss of trailer

attachment resulting in a vehicle crash and/or personal injury.

Use the hitch ball only for towing trailers or vehicles connected to the ball with a socket-type

coupler. The ball diameter must match the coupler socket size. Do not exceed the gross

trailer weight shown on the ball.

Improper tightening can cause hitch ball failure or loss of trailer attachment.

• The threaded shank must protrude beyond the bottom of nut when tightened. If it does

not, the ball shank is too short for the application and loss of attachment may occur.

• Check the nut tightness every time you hook up the trailer and at the beginning of each

towing day. Tow only if the nut is tightened as specied.

• Replace any damaged or worn parts (except nish).

• Never attach a tow rope, chain, or stretch type elastic rope to the hitch ball.

• Do not fasten the trailer safety chain or any other type of attachment to or with, the ball.

• Lubricate the ball and coupler to minimize wear and friction. The coupler must not bind on

the ball.

This product complies with V.E.S.C. Regulation V-5, C.S.A. Standard D-264 and the Safety

Specications and Requirements for Connection Devices and Towing Systems.

TRAILER MOUNT LONG-TERM STORAGE

When the sign is to be stored for extended periods of time, it is recommended to store the

unit outdoors and in a sunny area to allow the unit to maintain the charge on the batteries.

If it is to be stored indoors, keep the unit plugged into the AC charger when possible. When

the sign is to begin operation again, a thorough inspection of all systems is advised before

the sign is towed to the job site. Check the battery state of charge to conrm over 12 volts.

VEHICLE MOUNT LONG-TERM STORAGE

When the sign is to be stored for extended periods of time, the POWER switch should be

turned OFF. When the sign is to begin operation again, a thorough inspection of all systems

is advised before the sign is into operation.

BEFORE BEGINNING TRAILER SETUP:

1. Check the charge on the controller/battery level.

2. Check all jacks to make sure they are properly attached.

TRAILER SETUP

1. Position the trailer in the desired location so that the unit is directed toward trac.

2. Chock the trailer wheels and remove the trailer from the vehicle.

3. Use jacks to brace and level trailer.

4. Remove tongue from trailer (if desired).

ELEVATING SIGN

1. Verify that the display is in the proper position and that the

entire unit is level.

2. Clear all unnecessary personnel from the sign area to

ensure safety.

3. Unlock the hand brake before attempting to

RAISE/LOWER the mast to prevent damage.

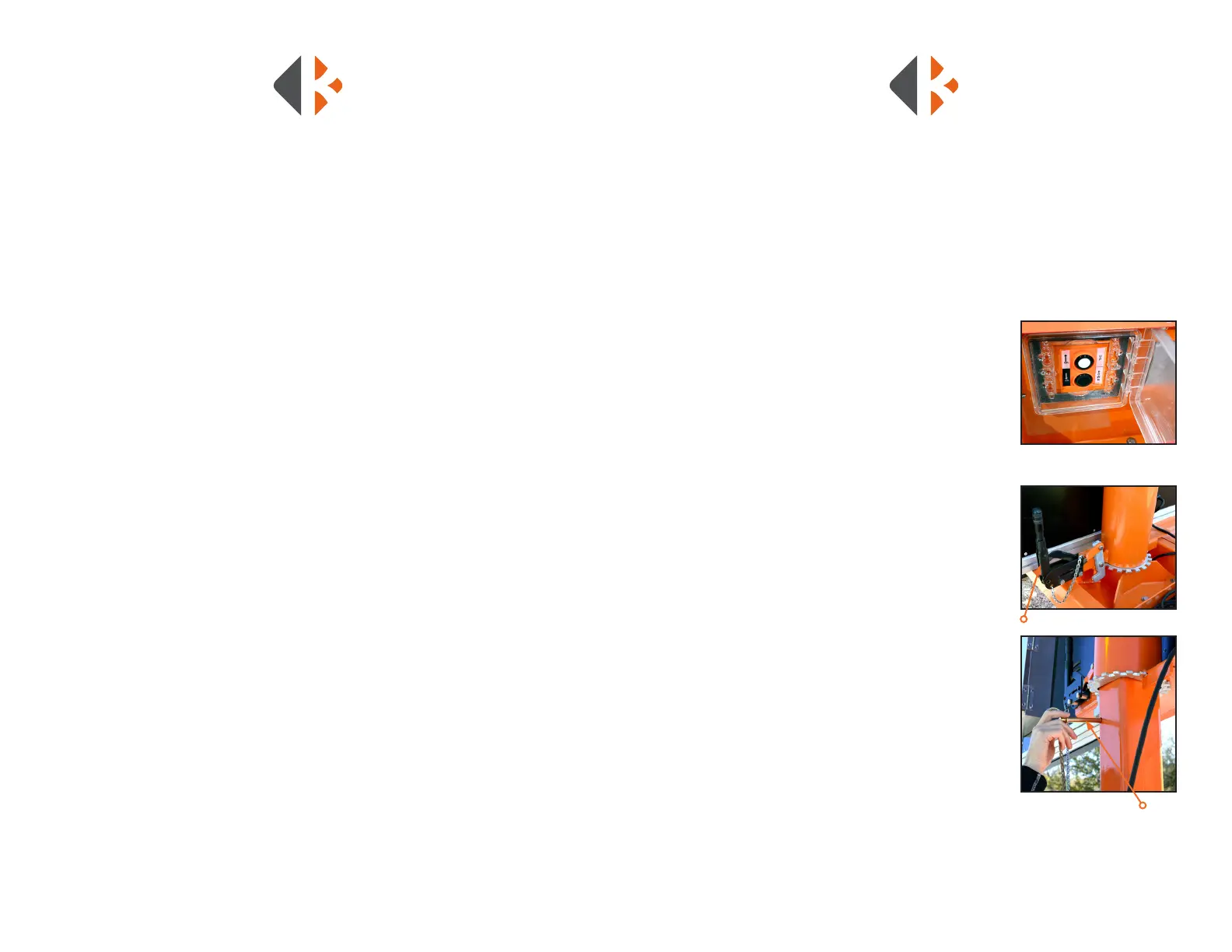

4. Locate the toggle switch marked RAISE/LOWER on the

controller located on the outside of the battery box.

The switch is protected by a clear plastic cover.

5. Hold the switch in the “RAISE” position until the mast raises

10-12” to check for proper alignment with trac.

6. If not properly aligned, release the hand brake and turn

the sign toward trac. Lock hand brake in the desired

direction.

7. Finish raising the display to desired height.

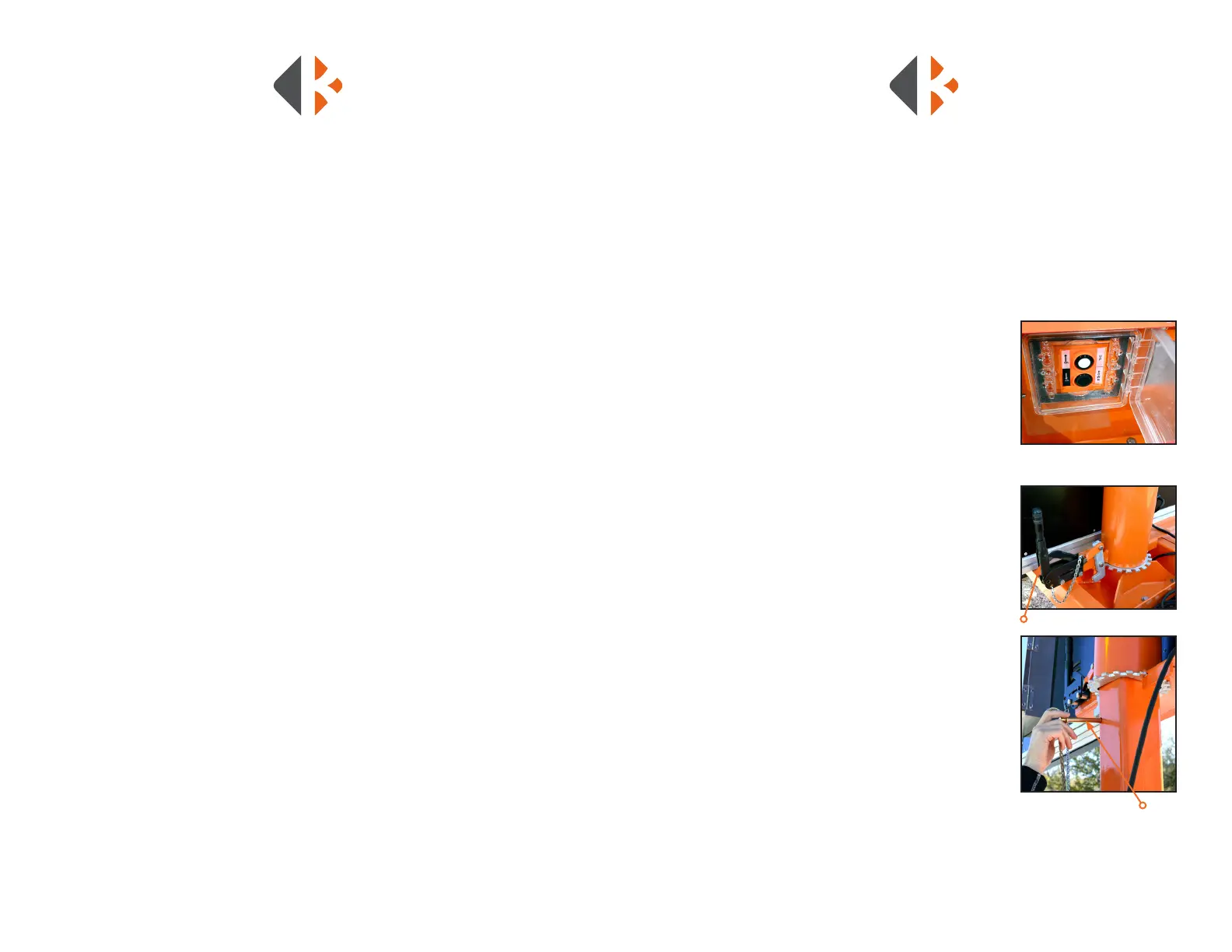

8. Insert the locking pin into the hole in the inner mast shaft.

(CAUTION: The locking pin can only be inserted if the mast is at its

maximum height).

LOWERING SIGN (CAUTION: The display can stick

when elevated on new units. Gently move the display back and

forth to loosen).

1. Verify that the unit is level.

2. Clear all unnecessary personnel from sign area to ensure

safety.

3. Remove the Locking Pin from the inner mast shaft.

4. Hold the switch in the “DOWN” position until the unit is

approximately 10-12” from the docking station.

5. Unlock the hand brake and turn to align with the docking station.

6. Lower the display completely into docking station.

7. Lock the hand brake.

TRAILER SETUP

Caution: Contact your dealer or manufacturer if any portion of this instruction guide is not understood.

Raise/Lower Switch located on

the side of the battery box.

Hand Brake

Remove the Locking Pin

before lowering.

Loading...

Loading...