13

3.3.5 Motor Overload Protection

The COMBIVERT F5 motor control by default provides motor overload protection at 130% of

the unit’s rated output current. See tables in section 2.3 for rated output current. Two additional

motor overload protection systems are avaialble.

Electronic Motor Overload Protection

This software function provides speed dependent I

2

t overload protection and is approaved by UL

as a solid state overload protection device according to UL508C section 42 and NEC 430 Part

C. The trip current is adjustable as well as whether the motor is self cooled or blower cooled.

Consult the F5B/G Application instruction manual for adjustment details.

Motor Winding Temperature Sensor

• Connects to Terminals T1, T2

• Trip resistance level 1.65...4 kΩ

• Reset resistance level 0.75...1.65 kΩ

• This function can be activated or deactivated through a software parameter. The default setting

is OFF!

• Do not run temperature sensor wires in the same conduit or wire way as other control cables.

These sensor wires most likely are carrying high frequency noise from the motor.

• If the sensor wires are part of the motor cable they must be shielded independently from the

motor wires.

Installation and Connection

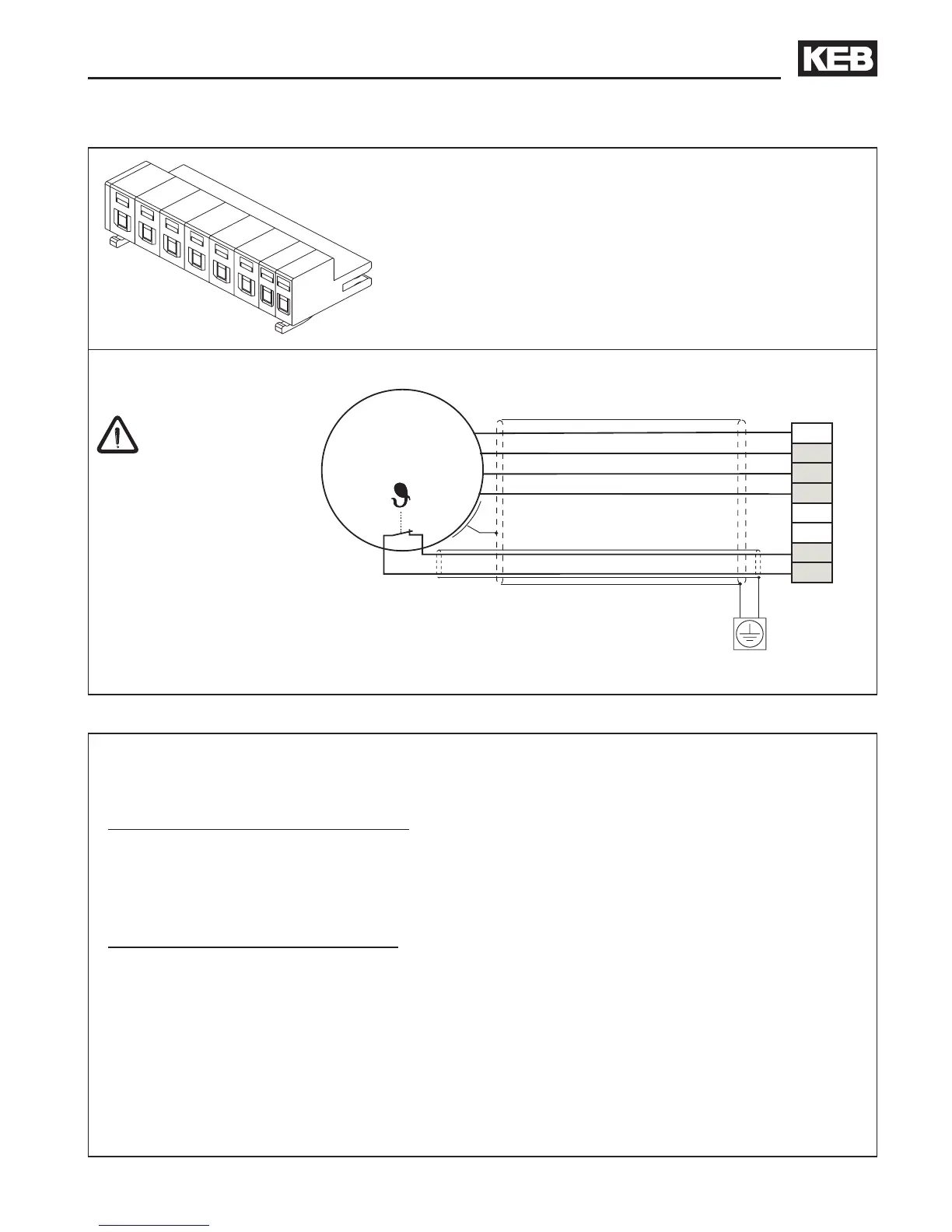

3.3.4 Motor connection

The maximum

m o t o r c a b l e

length listed in

the tables in section

2.3 is based on several

factors: use of shielded

motor cables, ground

current limitations,

increased EMI noise

levels, voltage peaks at

the motor terminals.

Connect shield to the mounting

plate with maximum surface area

(use metal cable clamp)

Terminal X1B provides connections for:

• ++, PB Braking resistor

• U, V, W Motor

• T1, T2 Temperature sensor

Terminal strip X1A

Provides connections for:

• 230 V AC / 1-phase (L1/L2)

• 230 V AC / 3-phase (L1, L2, L3)

• DC-Supply 250...370 V DC (++, --)

Loading...

Loading...