SERVICE MANUAL

KEMPACT RA_V_1.2

36 (40)

Kemppi Oy

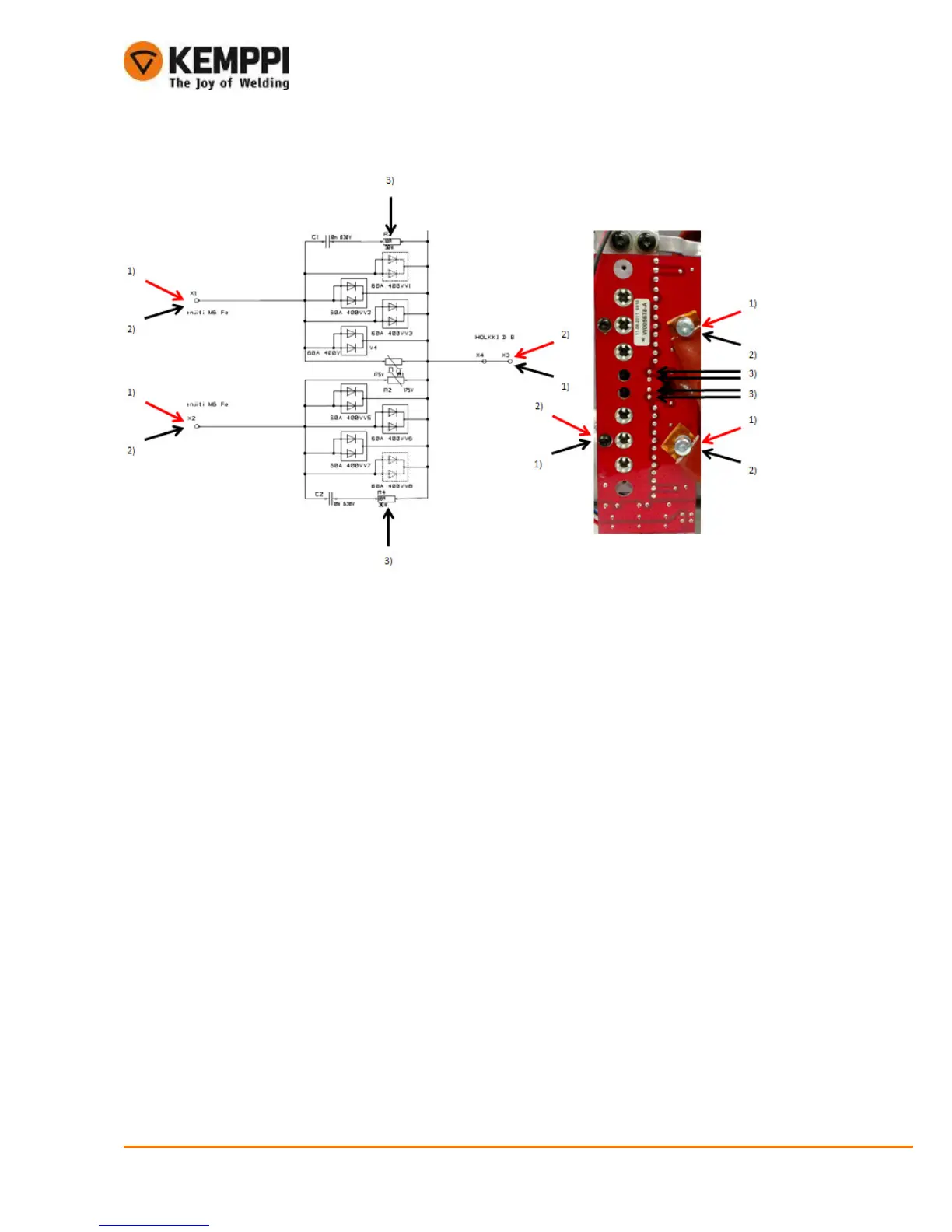

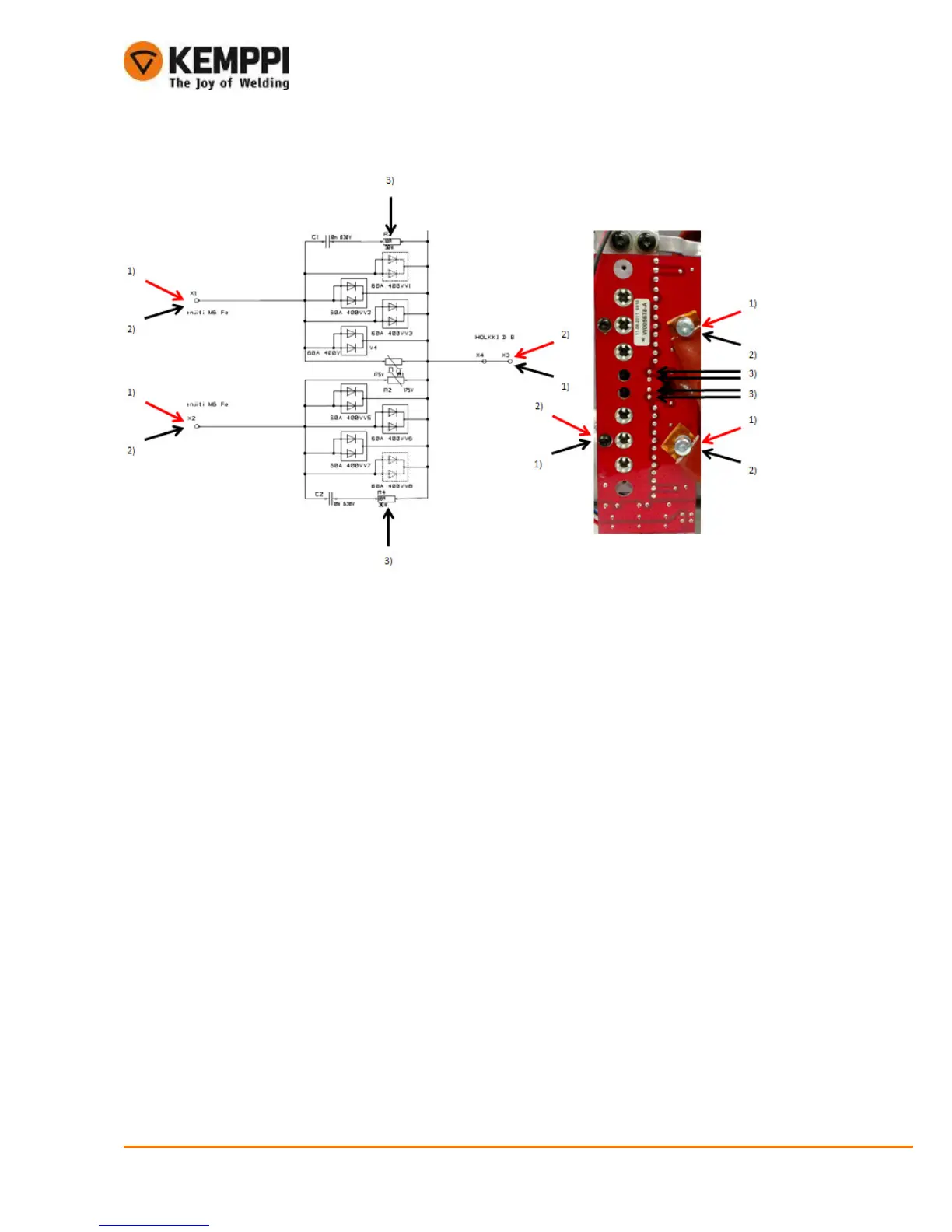

3) Snubber resistors R3 and R4

Result: value ~10 Ω

8.5. PTC’s, overheat protection

• There are two PTC’s in machine

o Main transformer Rt101 140 °C, value ~94 Ω in room temperature (connector 12, blue/white)

o Secondary profile Rg201 90 °C, value ~63 Ω in room temperature (connector 11, green/green)

o In over temperature situation PTC goes to high-resistance mode (>10kΩ)

o A broken PTC has usually hundreds of kilo ohms resistance or no value at all

8.6. Control card A001

• Control card voltages can be quickly verified with LEDs on the control card A001

9. MAIN COMPONENTS INSTALLATION

• Heat sink paste should be spread on to the modules in an even layer by using clean fingers. Then the card should be

immediately mounted onto the heat sink, this minimizes the possibility of any contamination (dirt etc.) getting

between the components.

• Use torque screwdriver when tightening any power components onto the heat sink. See following sections for

tightening torques.

9.1. Main circuit card Z001

• Primary rectifier V1 to heatsink 2 NM

• IGBT unit to heatsink

o First step 2 NM and wait a couple minutes

o Second step 3 NM

• Main circuit card Z001 to profile holder 0,7 NM

• Primary unit to component frame 2 NM

Loading...

Loading...