SERVICE MANUAL

KEMPACT RA_V_1.2

38 (40)

Kemppi Oy

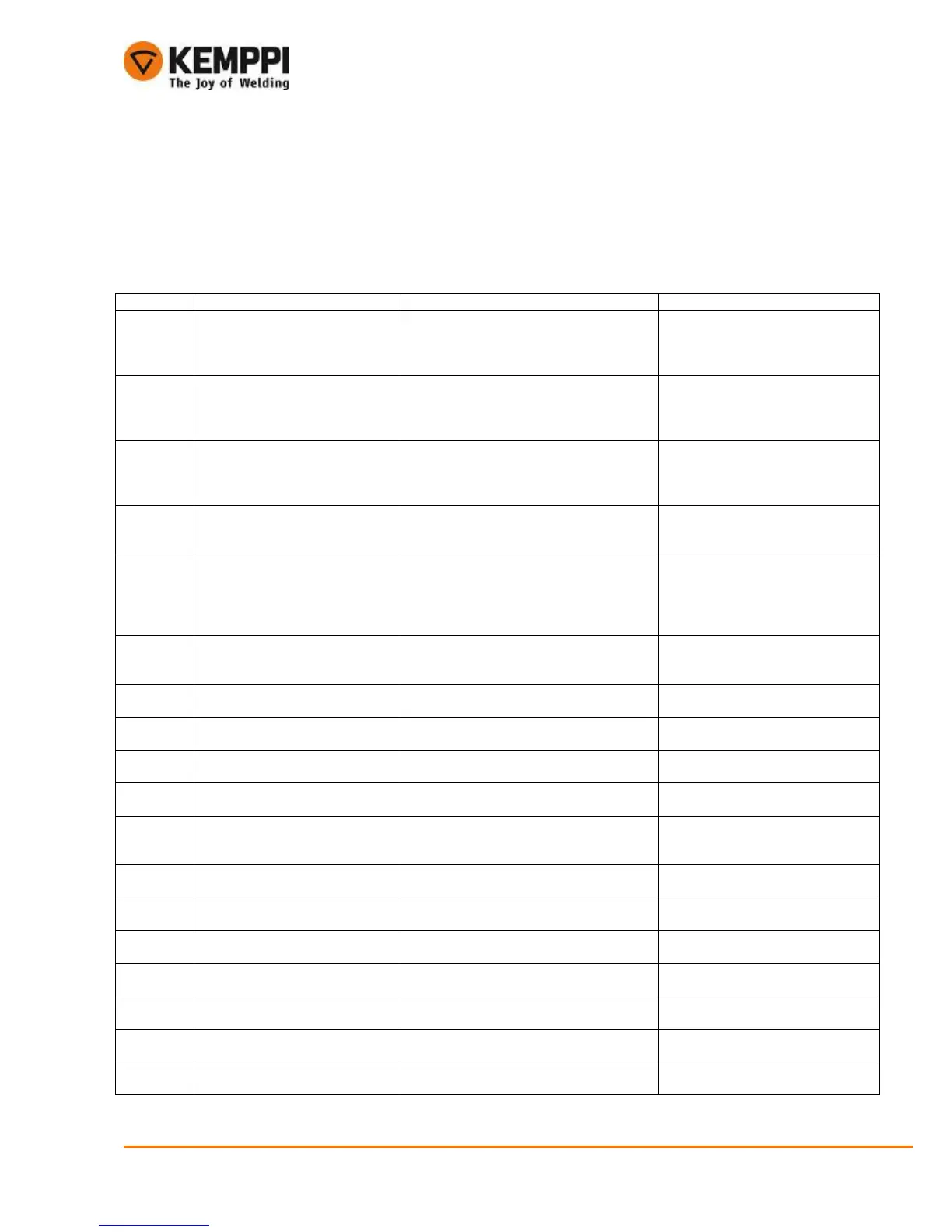

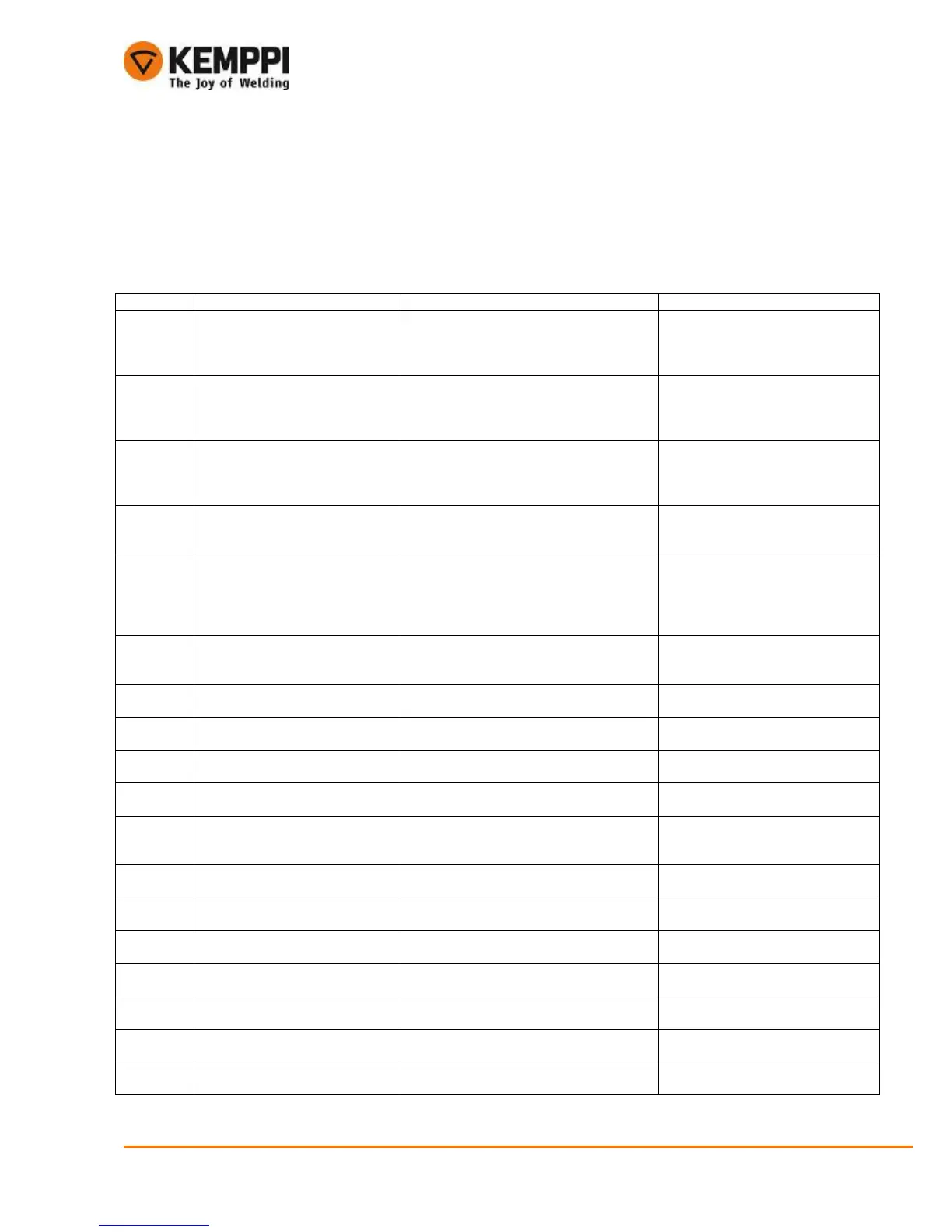

10. ERROR CODES

• In error situation welding is stopped and an error code is displayed on the panel

• The user can clear the error by pressing any of the panel buttons and if certain conditions are fulfilled

• If there are multiple errors at the same time only one can be displayed at a time. After user has cleared one error

next is displayed and so on until there is no more errors

Error code Error Reason Action / remedy

-181 model: 195 V

-251 model: 204 V

-253, 323 models: 340V

-mains over voltage error can be

cleared after mains voltage has risen

over low limit.

3 Mains over voltage -mains voltage is over high limit:

-181 model: 265 V

-251 model: 276 V

-253, 323 models: 460V

-check mains voltage

-mains over voltage error can be

cleared after mains voltage has fallen

under high limit

4 Wire feed motor over current -wire feed motor current (6 amps longer

than 60 s) is too high

-motor is jammed longer than 60 s

-this error can be cleared after weld-

ing has stopped due to this error

-check wire feeding motor and mech-

anism

5 Wire feed motor control not

calibrated

-calibration parameters have been corrupted

-faulty control card A001

-start up machine (on/off)

-change control card A001

6 Power source control not

calibrated

-power source control calibration parame-

ters are not in predefined limits

-calibration parameters have been corrupted

-faulty control card A001

-start up machine (on/off)

- change control card A001

User interface memory error

-used wrong welding parameters (improper

value)

start up machine (on/off)

-check welding parameters

8 Memory channel 1 error -memory channel data is invalid / corrupted -start up machine (on/off)

-check welding parameters

memory channel data is invalid / corrupted

start up machine (on/off)

-check welding parameters

10 Memory channel 3 error -memory channel data is invalid / corrupted -start up machine (on/off)

-check welding parameters

11 Memory channel 4 error -memory channel data is invalid / corrupted -start up machine (on/off)

-check welding parameters

12 Continuous short circuit in the out-

put of the power source

-there is continuous (over 2s.) short circuit in

the output of the power source.

-remove short circuit from machine

output (contact tip is connected /

short circuited in welding piece)

100 Microcontroller error -microcontroller reset. Possible reason: tig

ignition spark.

-start up machine (on/off)

101 Microcontroller error -microcontroller reset. Possible reason:

flash memory has been corrupted

-start up machine (on/off)

microcontroller reset. Possible reason: ele

tromagnetic disturbance

start up machine (on/off)

103 Microcontroller error -microcontroller reset. Possible reason: elec-

tromagnetic disturbance

-start up machine (on/off)

110 Panel communication error -communication error between panel card

P001 and control card A001

-check flat cable/connectors between

panel- and control card

111 Panel communication error -communication error between panel card

P001 and control card A001

-check flat cable/connectors between

panel- and control card

Panel communication error

communication error between panel card

P001 and control card A001

check flat cable/connectors between

panel- and control card

Loading...

Loading...