EN

Synergic Pulse MIG welding:

through this welding method, based on pulsing the welding current, the ller metal on the

workpiece is kept spatter-free. The power source pulse parameters change automatically

(synergy) enabling welding power regulation using a single knob. Choose the appropriate

synergy curve for the ller wire and shielding gas to determine how the wire feed speed

aects the pulse parametres.

Double pulse:

The wire feed will become higher or lower according to the wire feed range. While the

synergic welding parameters change to correspond to the momentary wire speed. The

purpose is to get a goodlooking weld and a proper penetration while improving the

controllability of the weld pool during position welding.

3.3.3 Selecting 1-MIG/Pulse MIG synergy curves

The program number of the synergy curve is selected using the plus-minus buttons and is

displayed on "SYNERGIC PRG".

The middle display is actual material group display (eg. SS, AL, CUS, FE, GEN). Wire diameter

(mm) can be seen on the right side. This information will only be displayed for a while.

The “PRG INFO” button gives more curve information:

One press will revert to the material group and diameter display, a second will display the type

number of the material and a third run through the gas consistency components one by one.

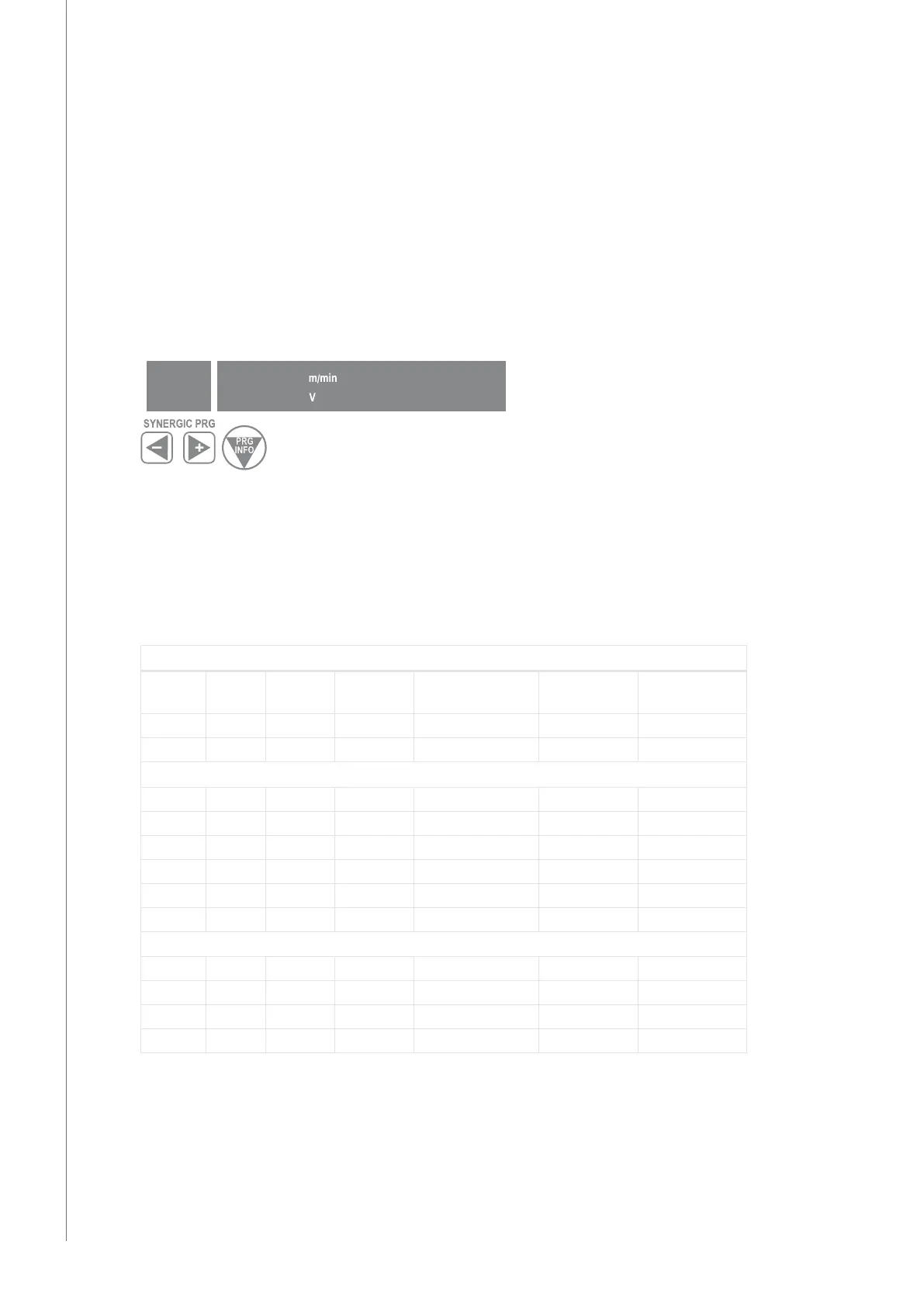

KEMPACT PULSE 3000 Synergic programs

1-MIG Pulse Double

Pulse

Wire, ø Material Gas Wire Feed Range

00 All All All 1,0 - 18,0

01 All All All 0,5 - 18,0

Ss-group

S1 S1 S1 0,8 mm SS 308 / 316 Ar + 2 % CO

²

S2 S2 S2 0,9 mm SS 308 / 316 Ar + 2 % CO

²

S3 S3 S3 1,0 mm SS 308 / 316 Ar + 2 % CO

²

S4 S4 S4 1,2 mm SS 308 / 316 Ar + 2 % CO

²

S5 0,9 mm SS 316 FC Ar + 18 % CO

²

S7 1,2 mm SS 316 FC Ar + 18 % CO

²

Al-group

A1 A1 A1 1,0 mm AlMg5 / AlMg4,5Mn Ar

A2 A2 A2 1,2 mm AlMg5 / AlMg4,5Mn Ar

A6 A6 A6 1,0 mm AlSi5 / AlSi12 Ar

A7 A7 A7 1,2 mm AlSi5 / AlSi12 Ar

Kempact Pulse 3000, KempactCool 10

12

Loading...

Loading...