EN

3.3.12 SETUP

Using the SETUP function, the user can change welding parameters which do not have their

own panel functions. These parameters can be set separately for 1-MIG and Pulse MIG. SETUP

settings are separate for each memory channel.

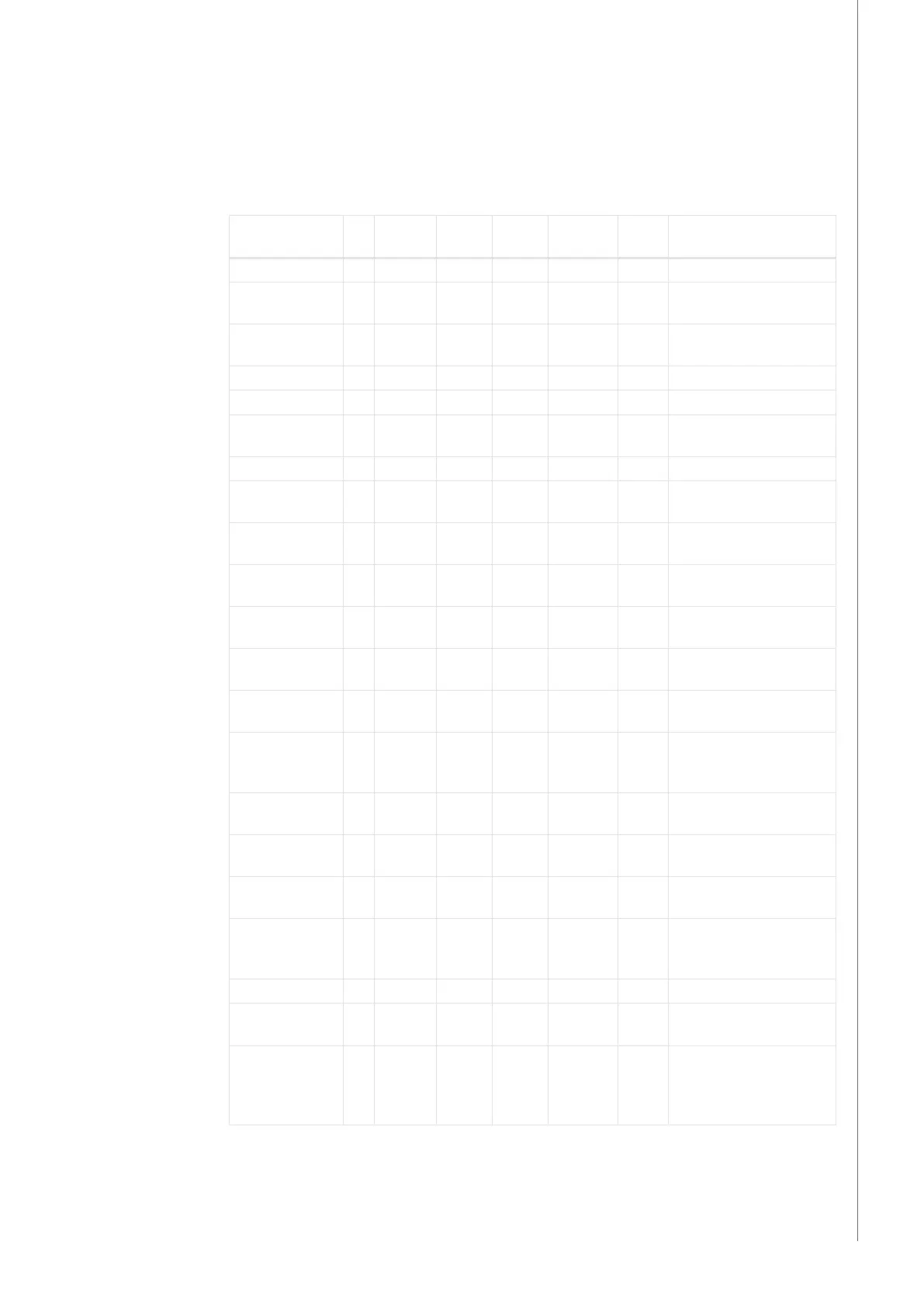

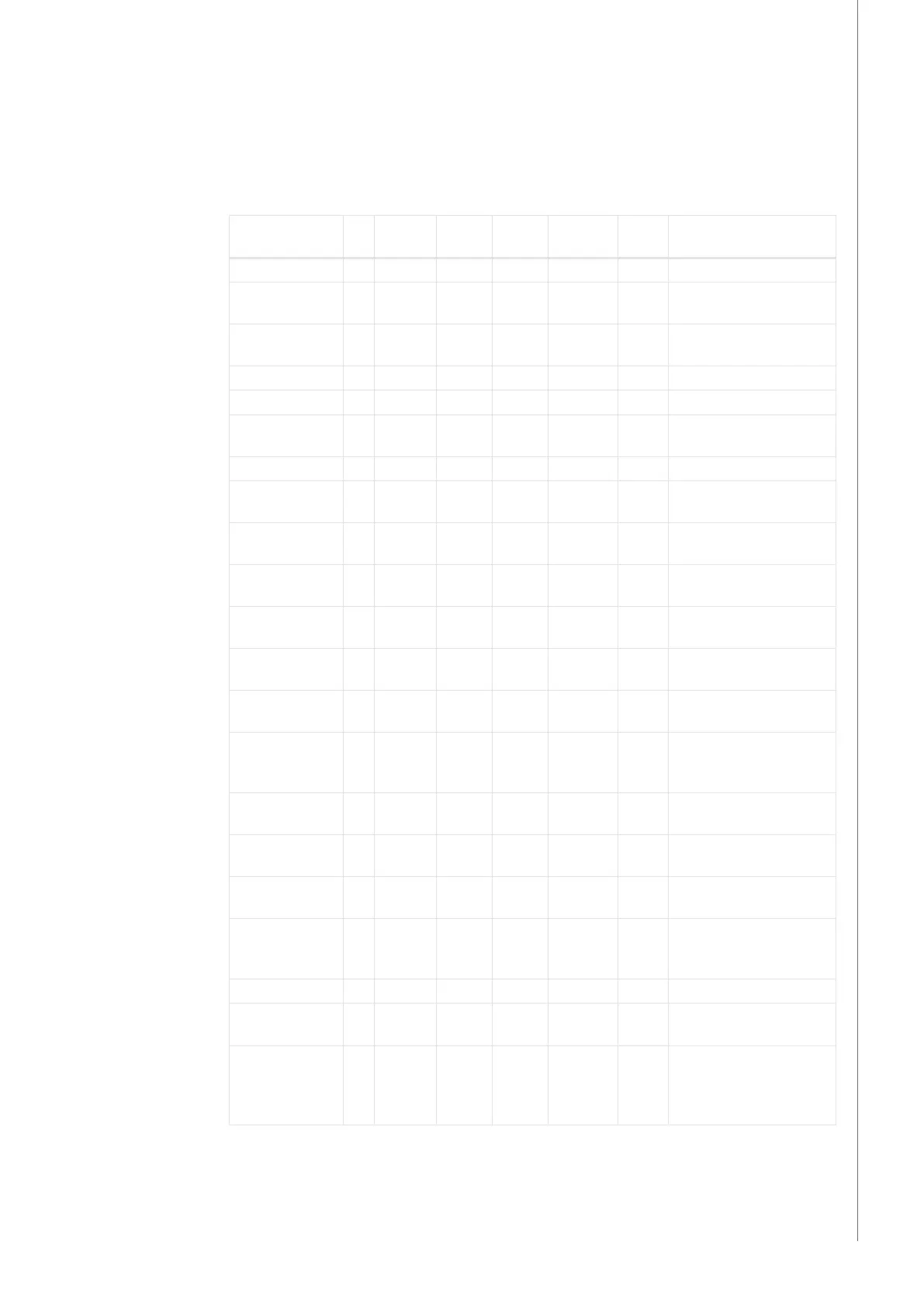

Setup functions on pulse panel

Parameter Name Nr Display 1-MIG Pulsed

MIG

Factory

value

Unit Explanation

PostGasTime

1 PoG X X Curve s PostGas time 0.0 – 9.9 s

PreGasTime

2 PrG X X Curve s PreGas time, functions by 2T

0.0 – 9.9 s

HotStartLevel

11 Hot X X 30 % Hot start ratio to welding power

-50 ... +75%

HotStartTime 2T

12 H2t X X 1.2 s 2T Hot start timer 0.1 – 9.9 s

CraterFillLevel

14 CFL X X 30 % Welding end level 10 – 90 %

CraterFillSlope

15 CFS X X 1 s/10m Wire slowing-down

1 – 20 s/10m

CreepStartLevel

17 CSL X X Syn Wire speed start value 10 – 90

CreepStartSlope

18 CSS X X 0 s/10m Wire speed up time

0 – 50 s/10m

DoubleFrequency

21 dFr X Curve Hz Double pulse frequency control

0.4 – 8.0 Hz

DoubleAmpiltude

22 dA X Curve m/min Double pulse power variation

control 0.1 – 3.0 m/min

StartPower

31 StP X X 0 Start power control

-9 ... 0 ... +9

PulseCurrent

33 PuC X 0 % Pulse top current control

-10 ... +15%

ArcLength

AdjRange

41 ALr X X 0 % Arc length adjustment range

-50 ... +75%

Calibration

42 CAL X X 1 V/100A Setting mid value of arc length

ne adjustment

0.0 – 10.0 V/100A

WFS

51 FS 18 m/min Wire feed maximum

18 or 25 m/min

Gun

53 Gun On Liquidcooled thermal protection

on/o

GunRemote

54 GrE On Disabling of gun remote control

automatic identication

Water Cooler

On/Off Selection

55 Coo On Set OFF after each power up if

cooler is connected with gas

cooled gun.

Display reset time

81 dLY X X 5 s 1 – 20 s

PRG INFO - feeld

selection

82 diS X X 1 1, 2, 3

Restore

99 FAC X OFF Restoring factory settings

(OFF=no reset,

Pan=panel and setup

ALL= also memory channels)

17

© Kemppi Oy / 1336

Loading...

Loading...