COPYRIGHT KEMPPI OY

18 / Kempomat 2500, Kempomat 3200, Kempomat 4000 / 0340

Kempomat 2500, Kempomat 3200, Kempomat 4000 / 0340 / 19

COPYRIGHT KEMPPI OY

7. OPERATION DISTURBANCES

The amount of use and the working environment should be taken into consideration when plan-

ning the frequency of maintenance of the Kempomat. Careful use and preventive maintenance

will help to ensure trouble-free operation.

The following maintenance operations should be carried out at least every six months.

Wire feed:

- The wear of the grooves of the feed rolls. Excessive wear of grooves causes problems in

wire feed.

- The wear of the wire guide tubes of the wire feeder unit. Badly worn feed rolls and wire

guide tubes should be dis carded.

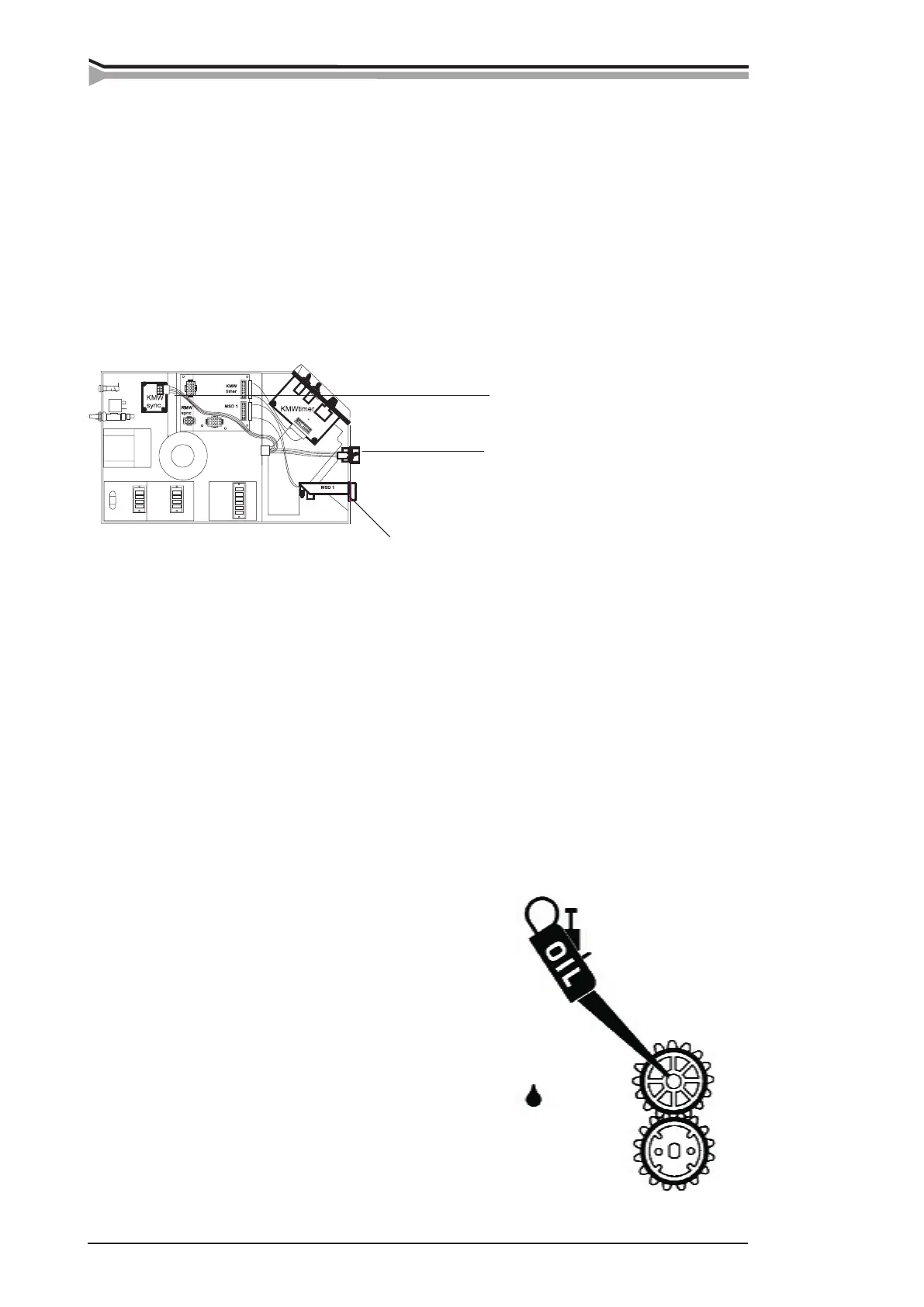

KMW sync control card

KMW sync

Mode selecting switch

Control connector for push-pull gun

(Binzel / Hulftegger)

MSD 1 V/A metering unit

- The wire guide tube should be set as near the feed rolls as possible, but not touching

them and the wire must follow a straight line from the end of the tube to the groove of

the feed roll.

- Reel brake adjustment.

- Electric connections

* Oxidized couplings must be cleaned

* Loose couplings must be tightened

Clean dust and dirt from the equipment.

When using compressed air, always protect your eyes with proper eye protection.

twice a year

Loading...

Loading...