23

Kemppi Oy

Heat sink paste should be spread on to the modules in an even layer by using clean fingers. Then the

card should be immediately mounted onto the heat sink, this minimizes the possibility of any contamina-

tion (dirt etc.) getting between the components.

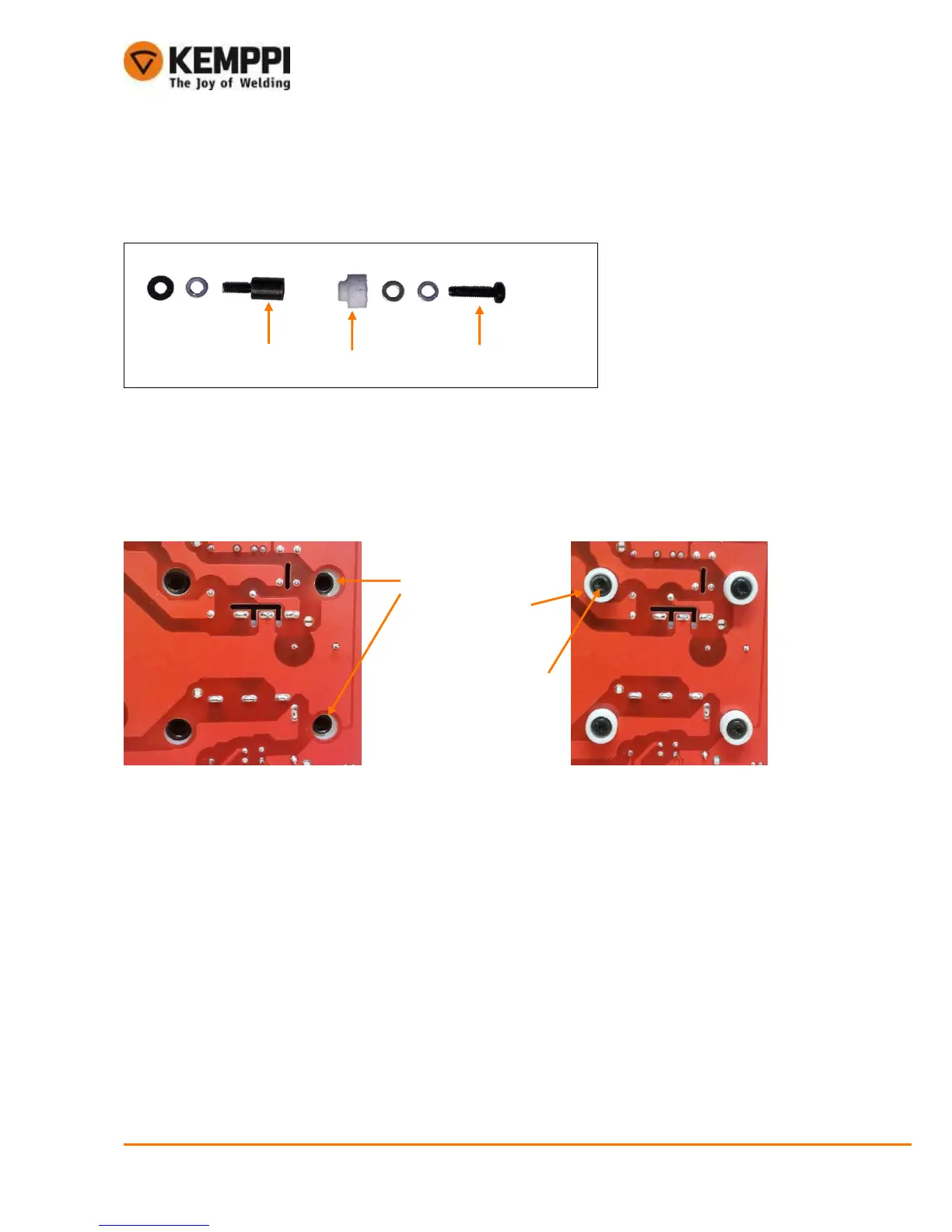

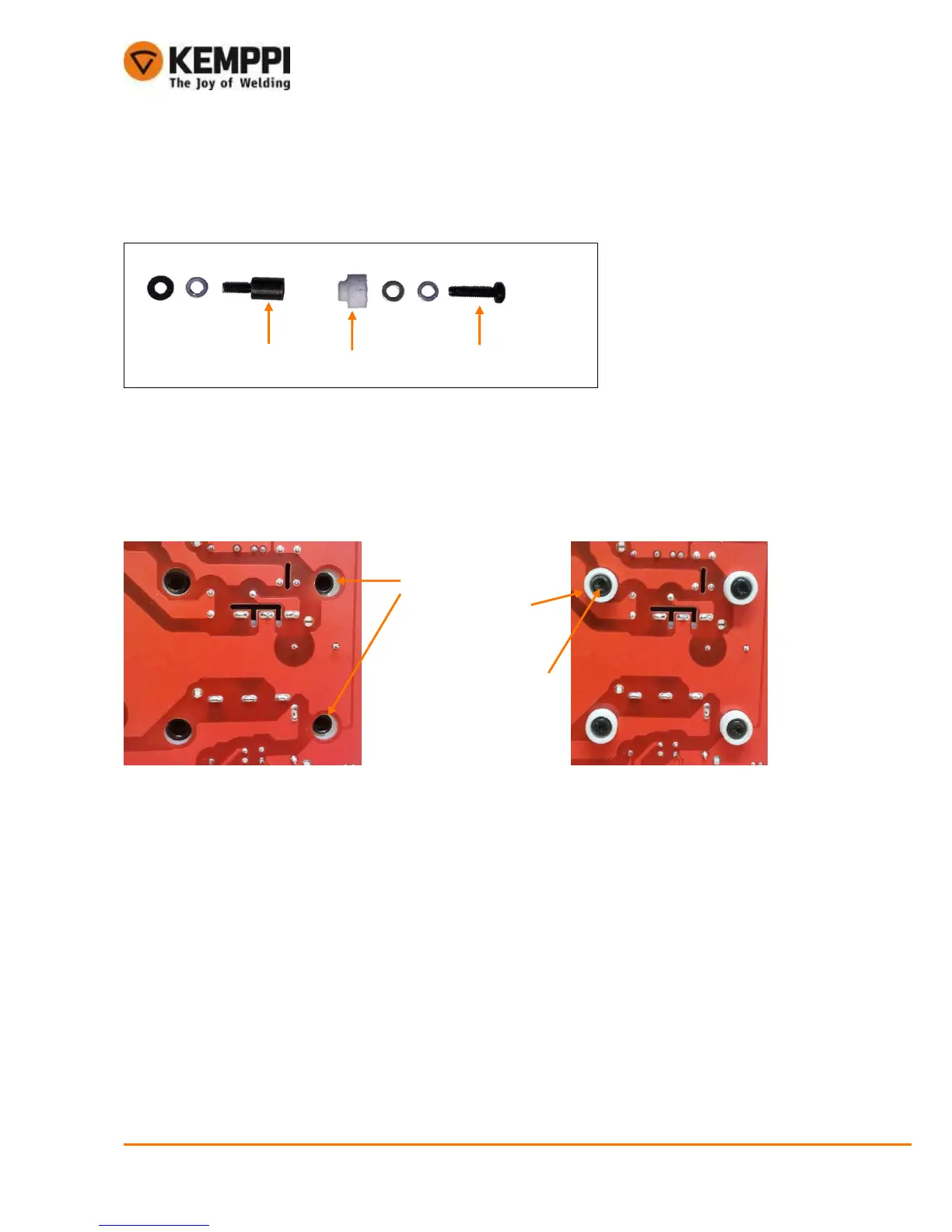

The hexagonal fixing screws on the IGBT module are tightened (stage 1) to 1 Nm. Then after a few

minutes the module screws can be finally tightened (stage 2) to a torque of 2 Nm.

Once all the four hexagonal screws are tightened to right torque, the Module support cap screws can be

fastened. The idea is to support the module onto the PCB with the plastic caps instead of the component

soldered legs. The torx screws with caps can be tightened only up to 0,5 Nm, or otherwise the PCB may

bend.

4.3.2. Secondary rectifier

Heat sink transfer should be spread in an even layer onto the heat sink. Then card should be immediately

mounted onto the heat sink. This minimizes the possibility of any contamination (dirt etc.) getting between

the components.

The torx fixing screws in diodes are tightened to 1,2 Nm and resistor (with smaller case than diodes) to

0,8 Nm.

4.4. Final testing

After machine repair and low voltage tests it is good practice to make some load tests and test welds.

Only then is it possible to guarantee the machine is working in real life welding conditions.

Loading...

Loading...