2.6 CONNECTING RODS

The connecting rods are made of nodular SG IRON,

fitted with split, white metal lined, precision steel

backed big end bearings and a push fit, bronze, small

end bearing bush. Internal oil ways permit oil to flow

from the big end bearing to the gudgeon pin bush, which

is adequately grooved for lubrication of the gudgeon

pin.

In case of 2 stage compressors, connecting rod with

needle roller bearing (on small end side) is used on high

pressure sides.

2.7 CRANKSHAFT

The crankshaft is accurately ground and dynamically

balanced, thus ensuring quiet operation good running

characteristics and high wear resistance. All bearing

Journals are precision machined to fine tolerances.

Internal oil ways feed oil to all main and big end

bearings (see fig. 6). The crankshaft rests on precision,

white metal lined walled bearings fitted in the crankcase

and bearing housing. In addition, in cases where

intermediate main bearings are fitted, these are of

similar construction as that of split big end bearing of

connecting rod. The bearing housing at the flywheel end

also incorporates the shaft seal which prevents the

passage of oil or refrigerant out of the crankcase.

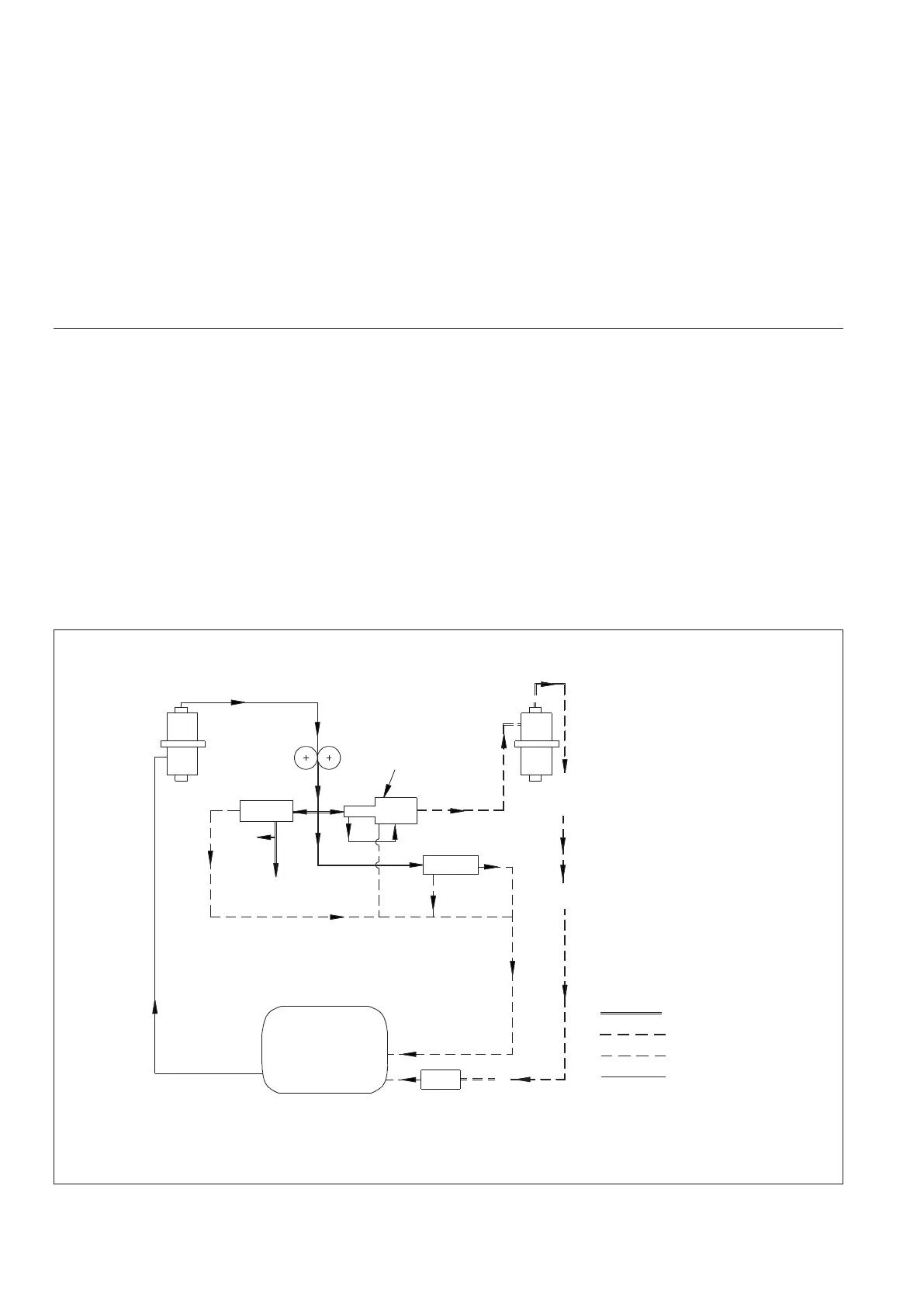

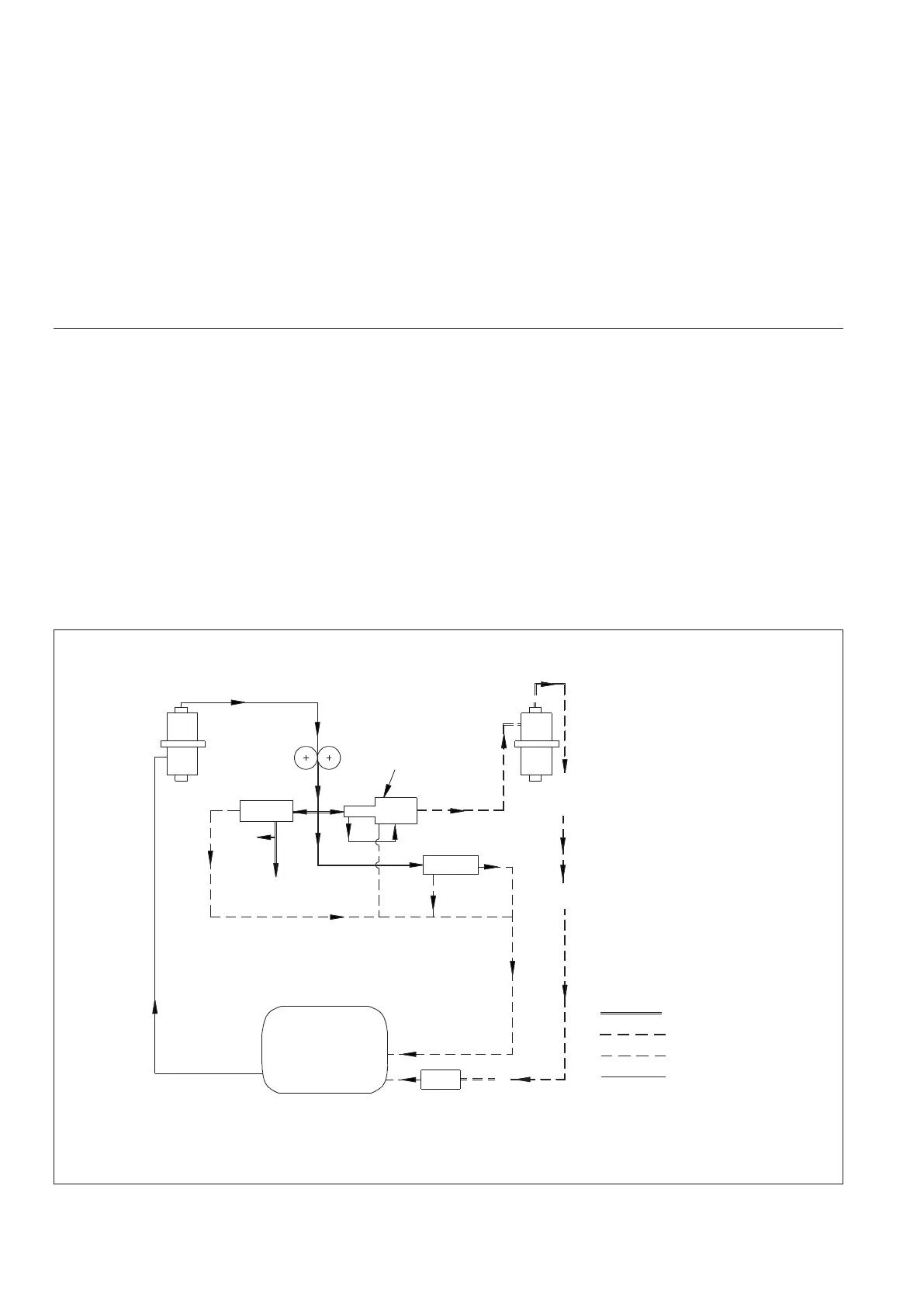

2.8 OIL PUMP

The compressor is fitted with a high pressure gear pump

provided with differential pressure regulator. In this way

a low pressure oil supply is made available for

lubrication purposes and a high pressure oil supply for

valve lifting mechanism. This high pressure oil supply

may also be used for capacity control, when installed.

The hydraulic time delay provides an interval of about ½

to 1 minute being the time necessary to enable the com-

pressor to start under "no-load" conditions. (see fig. 4)

The compressor is fitted with an adjustable oil pressure

regulator inserted in the oil return line. It is mounted

above the oil level glass, externally, on the crankcase.

. The regulator consists of a valve housing in which a

ball valve is held against the oil inlet by a spring. The

compression of this spring is adjusted by turning a set

pin, which is sealed by a nipple and washer, A cap.

which has to be removed before the oil pressure can be

adjusted, covers the nipple. After the cap has been

removed, the set pin can be turned with the aid of a screw

driver. To achieve a higher pressure, the set pin should

be turned in a clockwise direction. Within crankcase a

return line leads from the oil pressure regulator to the

level glass through which the oil jet can be observed,

(see fig. 5)

Figure 4 : Schematic Diagram of Oil Circuit

OIL PRESSURE REGULATOR

CRANKCASE

TO CAPACITY CONTROL

OIL PRESSURE GAUGE

CRANKSHAFT

SHAFT

SEAL

OVERFLOW RELIEF

VALVE

TO VALVE

LIFITING

DEVICES

HYDRAULIC

TIME DELAY

HIGH PRESSURE

OIL PUMP

OIL SUCTION STRAINER

OIL DELIVERY STRAINER

DIFFERENTIAL

PRESSURE

REGULATOR

CRANKCASE

HIGH PRESSURE

LOW PRESSURE

RETURN TO CRANKCASE

6

Loading...

Loading...