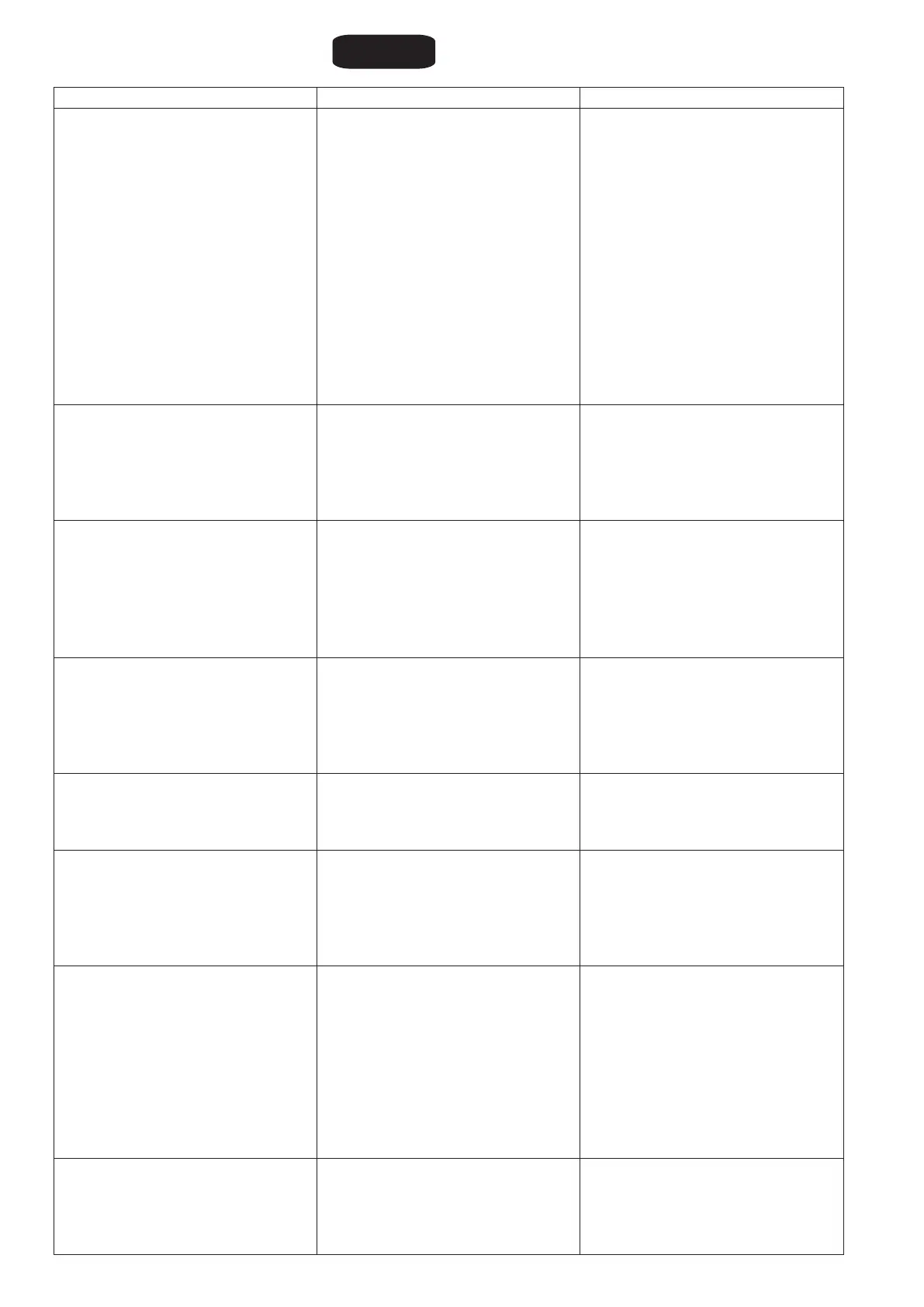

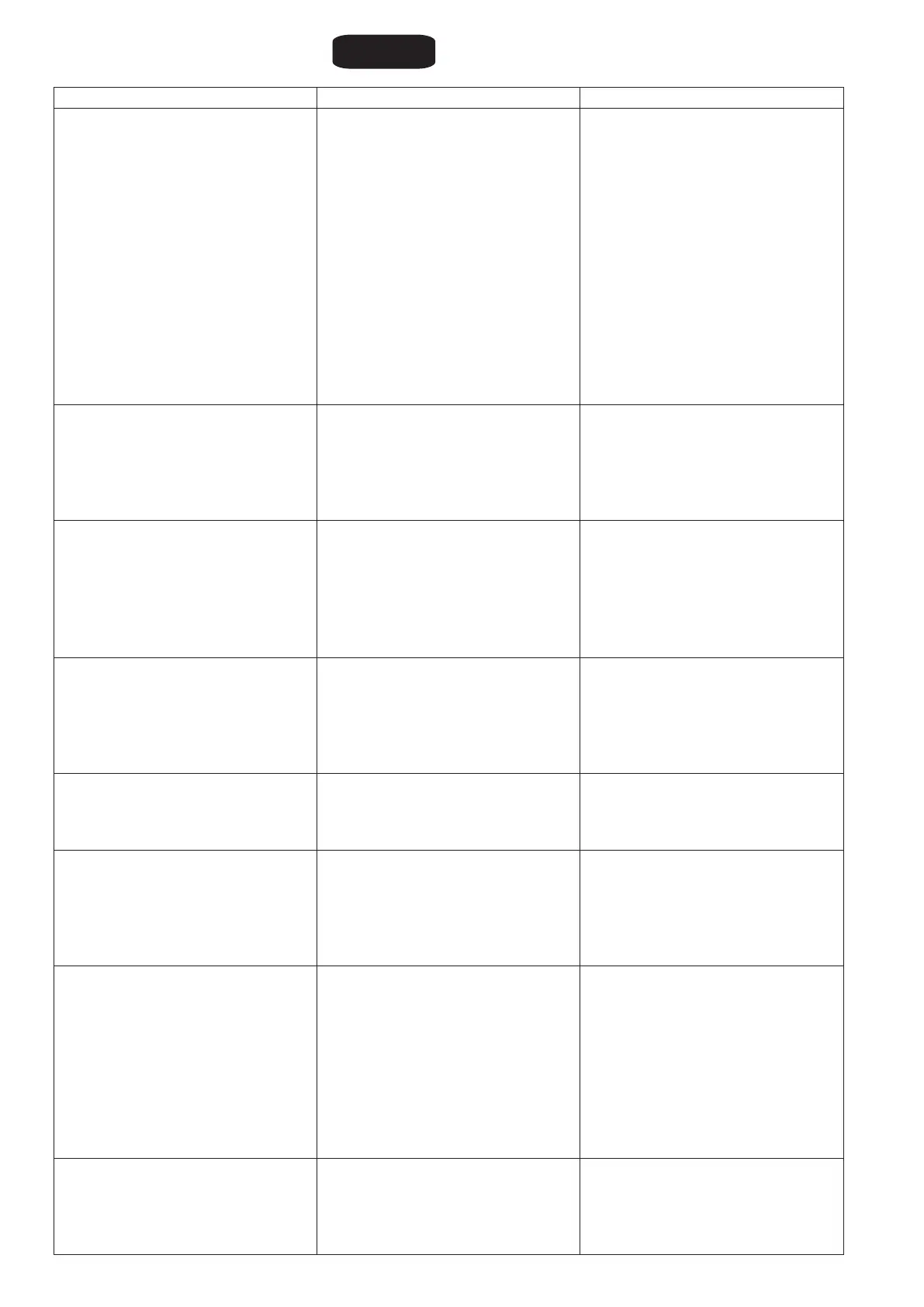

9.TROUBLE SHOOTING CHART:

Fault

Cause

Remedy

9.1 Deliery pressure too high (probably nDelivery stop valve not open wide Open fully

H.P. pressostat becomes operative) nLess or too warm cooling water nIncrease water supply

(On water cooled condensers the nGas suction pressure too high (during nPartially close suction stop valve

temperature indicated by delivery starting-up period only)

pressure gauge rises more than 6°C nSuction pressure higher than normal. nRefer fault No. 9.3

above that of cooling water outlet. nToo much refrigerant in condenser. nOpen liquid control valve further or

On aircooled condensers the temp- release some liquid from system.

erature indicated by delivery

pressure gauge rises more than

10°C above that of air temperature

at condenser outlet).

nCondenser tubes blocked or dirty. nClean condenser

nAir in the system. nPurge system.

nDefective delivery pressure gauge nRepair

9.2 Delivery pressure too low nLeaking H.P. safety valve nRepair/Renew

nSuction stop valve not open wide enough nOpen fully.

nSuction pressure lower than normal nRefer fault No. 9.4

nFaulty delivery pressure gauge nRepair/Renew

nDefective delivery valve nReplace.

9.3 Suction pressure too high nLiquid control valve open too wide. nReadjust setting.

nLeaking H.P. safety valve nRepair/Replace

nDefective pressure gauge nRepair/Replace

nCapacity control out of order (if fitted) nInspect and repair

nSuction or delivery valves defective. nRenew.

nExcessive leakage past piston nReplace piston rings.

9.4 Suction pressure too low (probably nSuction stop valve not open wide enough nOpen fully

L.P. pressostat operates) nLiquid control valve not open wide nOpen further

enough.

nRefrigerant suction strainer chocked. nClean

nLess refrigerant in system. nTop up with refrigerant.

9.5 Liquid stroke nLiquid control valve open too wide. nReadjust setting.

nCapacity control out of order (if fitted) nInspect and repair

nDefective evaporator float (if fitted) nInspect and repair or replace

9.6 Oil pressure too high during running Oil pressure regulator defective or Repair/Readjust

(during running-up period oil maladjusted.

pressure is always higher than Defective pressure gauge Repair/Renew

normal until operating temperature

reached)

9.7 Oil pressure too low (oil pressure Oil pressure regulator defective or Repair/Readjust

differential pressostat probably Insufficient oil in crankcase Top up with oil.

operates) Suction pressure too low See fault No. 9.4

Oil suction and/or delivery strainer Clean

blocked

Oil return pipe between crankcase and Clean out or repair

oil suction strainer blocked.

Slack bearings. Refit

Blocking of oil ways in crankshaft Clean-out.

9.8 Pressure difference between suction Suction pressure too high See fault No. 9.3

and delivery pressures too small. Delivery pressure too low. See fault No. 9.2

enough n

IMPORTANT

30

Loading...

Loading...