connection.

2. CONSTRUCTIONAL DETAILS

2.3 CYLINDER LINER

2.1 GENERAL

The renewable cylinder liners, made of fine grain cast

The compressor series KC comprises of 2, 3, 4, 6, 9, 12

iron centrifugally cast, are pressed into the cylinder

cylinders which are manufactured as single or two-stage

jackets and can be easily replaced. An extremely smooth

machines. These compressors are designed for

surface finish is obtained by precision boring and

Ammonia, Freon R134a refrigerants but can also be

honing. The collar at the top of the cylinder liner is

used for compression other gases. They are fitted with

provided with holes and serves as the valve seat for the

cylinders having a bore of 160 mm. The direction of

suction valve ring. The cylinders are numbered for ease

rotation is anticlockwise, while looking from the

of reference (e. g. in case of complaints, overhaul

flywheel end. Maximum safe delivery pressure for

2

reports etc.). Looking from the flywheel end, the

continuous operation is 20 kg/cm gauge. Minimum

numbering is from right to left and increases in the

speed is 450 rpm and the maximum 1000 rpm.

direction of the oil pump. Hence for a 6-cyl. compressor

2.2 CRANKCASE AND CYLINDER JACKETS

the first line of cylinders from flywheel end is numbered

from right to left, as 1,2 and 3. The second line from

Crankcase and cylinder jackets form a fabricated all

right to left is then numbered 4, 5 and 6.

welded, gas-tight steel structure, ensuring absolute

stiffness and mechanical strength, with a relatively low

2.4 VALVES

weight and a high impact strength. After welding, the

The suction and delivery valves are of ring type and of

complete unit is stress relieved and cleaned. The suction

special steel. Their design ensures ample gas passage

inlet to the compressor is through suction manifold in

with a minimum lift. The suction valve seat machined

which a removable strainer is fitted, thus ensuring that

on the upper face of the cylinder collar and the suction

the suction gas is filtered before entering the

valve ring is held into this seat by two sinusoidal springs

compressor. The suction manifold is connected to the

between the valve seat type collar of the cylinder liner

space between the cylinder liner and jacket. In this space

and a stroke limiter. This stroke limiter also locates the

any oil entrained in the gas is partially separated out and

delivery' valve seat and is centered by the collar of

is returned to the crankcase via a non-return valve. In the

cylinder liner.

H.P. cylinders of two-stage compressors, this non-return

valve is replaced by a plug, as the space round the H.P.

The three delivery valve rings with their valve springs

cylinder liner, being under intermediate pressure should

and the stroke limiter are assembled to the delivery

not be in connection with the crankcase where a lower

valve seat by means of a centre bolt with nut. This unit is

pressure (L. P. suction pressure) prevails. An open

held against the suction valve stroke limiter by a heavy

connection would cause a considerable reduction in

buffer spring. This construction enables delivery valve

compressor capacity.

seat as well as the stroke limiter to lift in case of liquid

stroke to avoid undue material stresses.

The cylinder heads are provided with cooling water

jacket fitted with inlets and outlets (3/4" BSP sockets).

2.5 PISTONS

Cooling is adopted if the compression temperature is

The light-alloy pistons are die cast and provided with

higher than 120°C. The cooling water should be non-

three piston rings and two scraper rings, one of the later

corrosive. The cooling water discharged from the

being positioned below the case hardened and ground

condenser should be used for cylinder cooling as the

steel gudgeon pin. Due to this an extremely good piston

water inlet temperature to the cylinder jacket must

seal is obtained, none the less providing adequate

exceed the condensation temperature of the refrigerant.

lubrication together with minimum oil consumption.

The manifolds are provided with pressure gauge

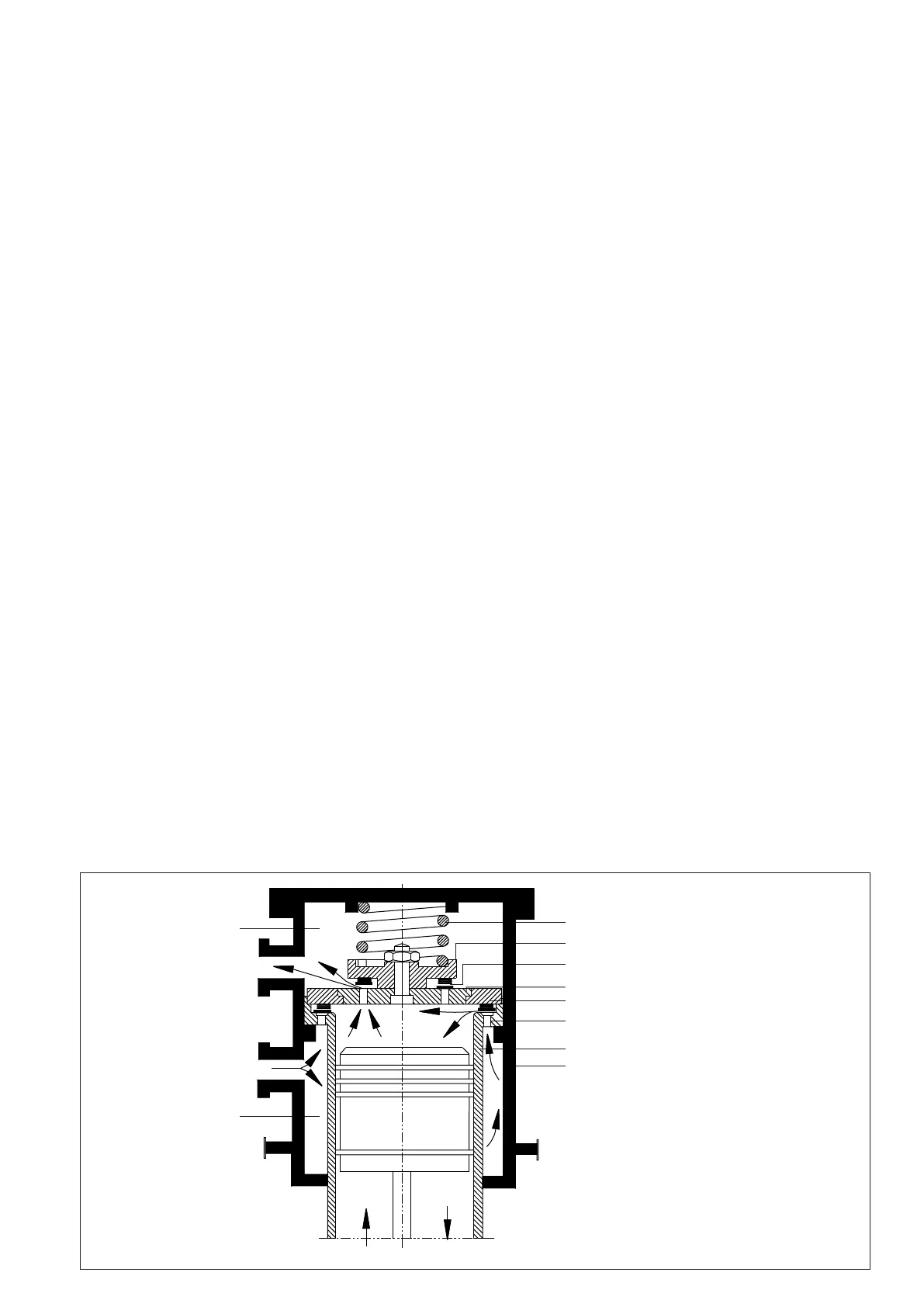

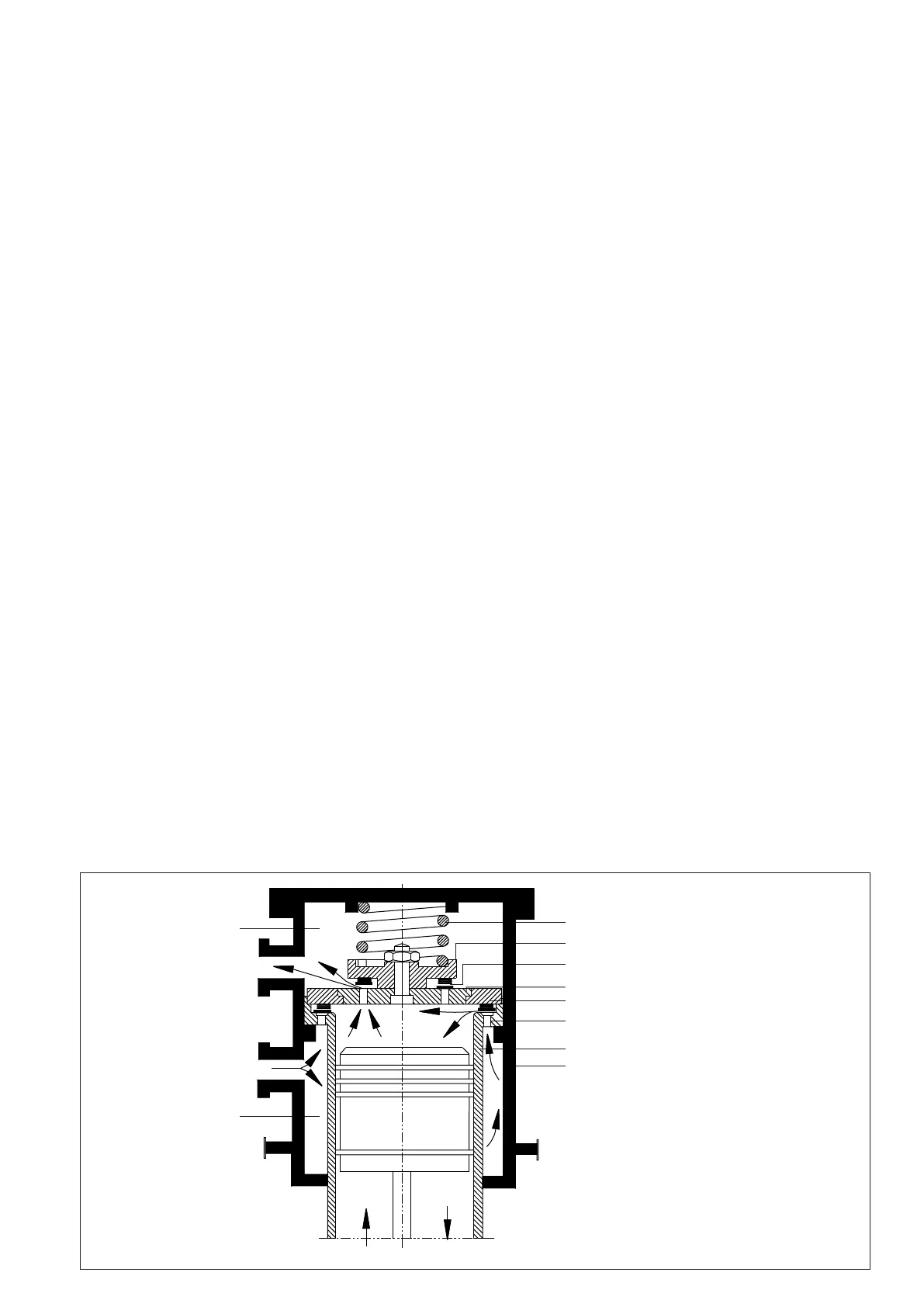

Figure 3 : Schematic Construction and operation of suction and discharge valve

1. Buffer Spring

2. Discharge Valve Stroke Limiter

3. Discharge Valve with Springs

4. Discharge Valve Seat

5. Suction Valve Stroke Limiter

6. Suction Valve Ring with Springs

7. Cylinder liner, also suction valve seat

8. Cylinder Jacket

1

2

3

4

5

6

7

8

DISCHARGE

CHAMBER

SUCTION

CHAMBER

5

Loading...

Loading...