22

6. PARALLEL OPERATION OF COMPRESSOR

GENERAL

Whenever two or more compressors are installed with

common suction header piping and these compressors

are operating simultaneously, the operation is called as

parallel operation of the compressor. In this case,

discharge line of individual compressor may be either

connected to common discharge header or separately to

individual condensers.

During operation, the oil return from evaporator(s) will

not be uniform to the crankcases of different

compressors. This may cause shortage of oil in some

compressors and excess in other, leading to failure of

compressor. To overcome this situation following

precautions are necessary to be taken during

installations :

INSTALLATIONS PRECAUTIONS

1. See that all compressors are installed in same

horizontal level.

2. Connect all compressors by oil equalizing line with

isolating valve in between each pair of compressor.

Oil equalizing line must run in level with oil

equalizing tapping or below the oil level of the

compressor. Under no circumstances this line

should run at level higher than compressor oil level.

3. Connect all compressors by crankcase gas

equalizing line with isolating valve in between each

pair of compressor. Under no circumstances this

line. should run below than that of crank case gas

equalizing tapping provided on crankcase.

4. For multiple condensing units interconnect all

condensers to equalize condensing pressure with

proper isolating valves.

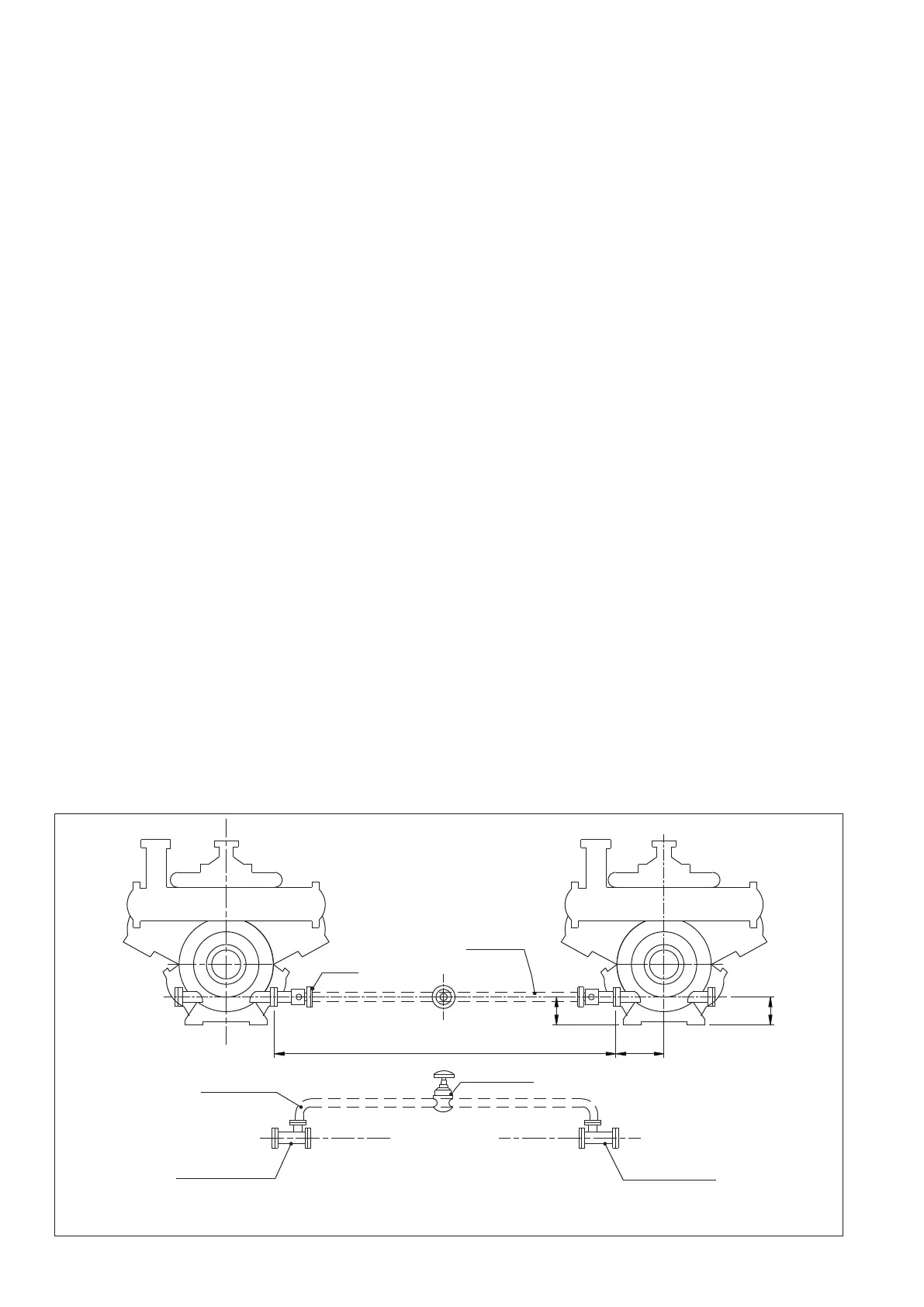

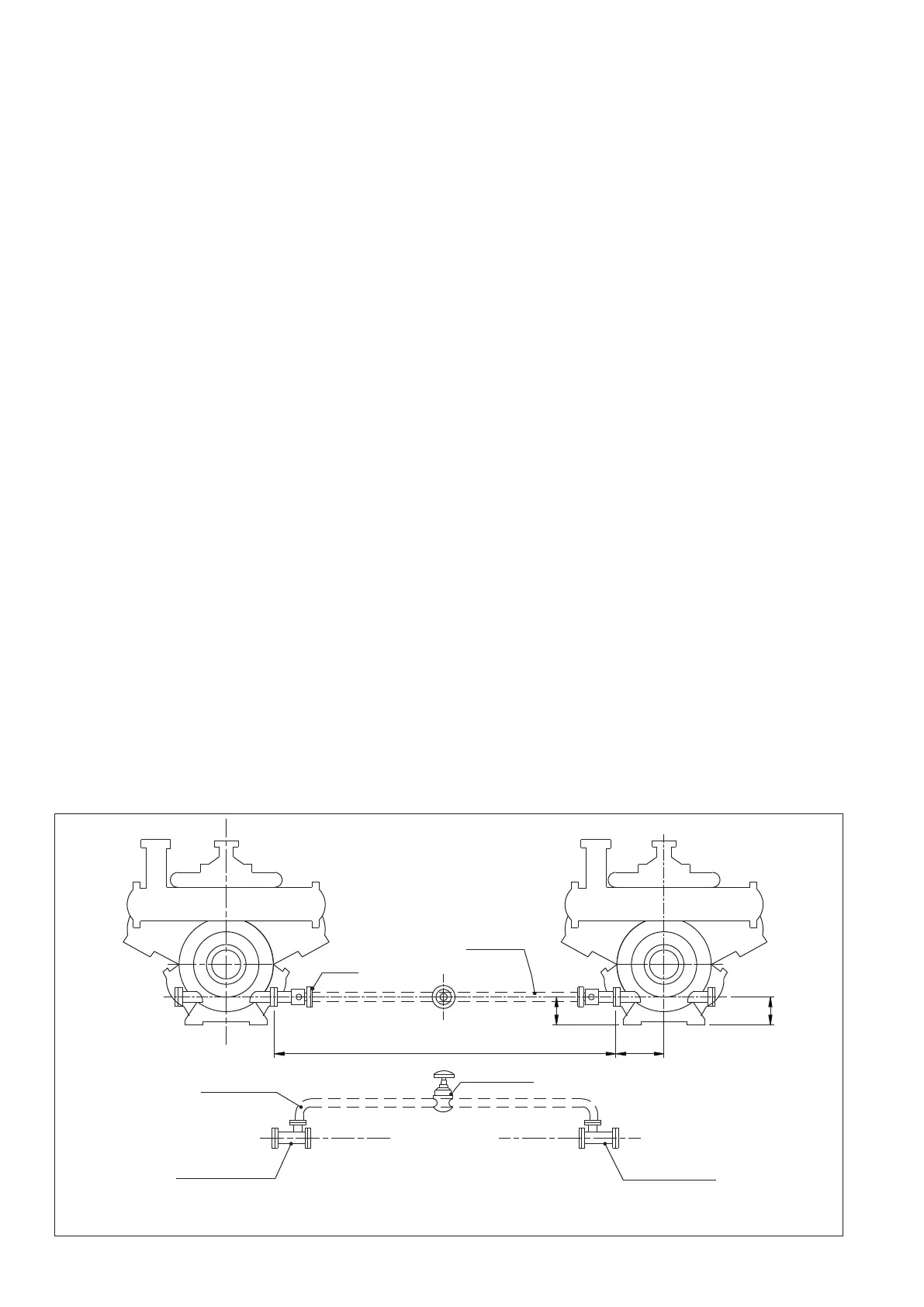

A construction whereby just one horizontal line with

ample diameter, fitted between two adjacent

compressors onto their sight glass connections, serves

both purposes, viz to maintain equal oil levels as well as

equal crankcase pressure. See figure 25 for reference.

Figure 25

No extra gas equalizing lines are necessary because the

vertical location of the oil equalizing line is such, that

the prescribed oil level in the crankcase is approx, half

way this line thus leaving ample passage to equalize the

crankcase pressures as well.

A stop valve in the equalizing line should be mounted

with the spindle in a horizontal position in order to avoid

the interruption of the oil level , when the valve is open.

We can supply a set of oil and gas equalizing line

consisting of

a) TAL valve type 40.

b) Tee connection left

c) Tee connection right

d) Joining 40 NB steel pipe

The number of parallel compressors to be

interconnected in this way should be restricted to three,

whereby the length of the equalizing line between the

sight glasses of two adjacent compressors should

preferably not exceed 2 mtrs.

Moreover, it is recommended always to provide each

compressor with an individual oil separator and

corresponding oil return line to its crankcase.

OPTIONAL INSTRUCTIONS:

1. Before starting all these parallel connected

compressors, OPEN fully. isolating valves installed

in gas and oil equalizing line and then follow other

instructions for starting the plant.

2. If one of the compressor needs to be cut off from the

operation CLOSE fully isolating valve related to the

compressor to be cut off and then follow other

instructions for stopping the concern compressor.

245

OIL LEVEL

SIGHT

GLASS

STEEL PIPE

Ø48.3x2.6 mm

TEE CONNECTOR

RIGHT HAND TYPE

SIGHT GLASS

TEE CONNECTOR

LEFT HAND TYPE

STOP VALVE

TYPE TAL 40

MAX 2000

140

147

Loading...

Loading...