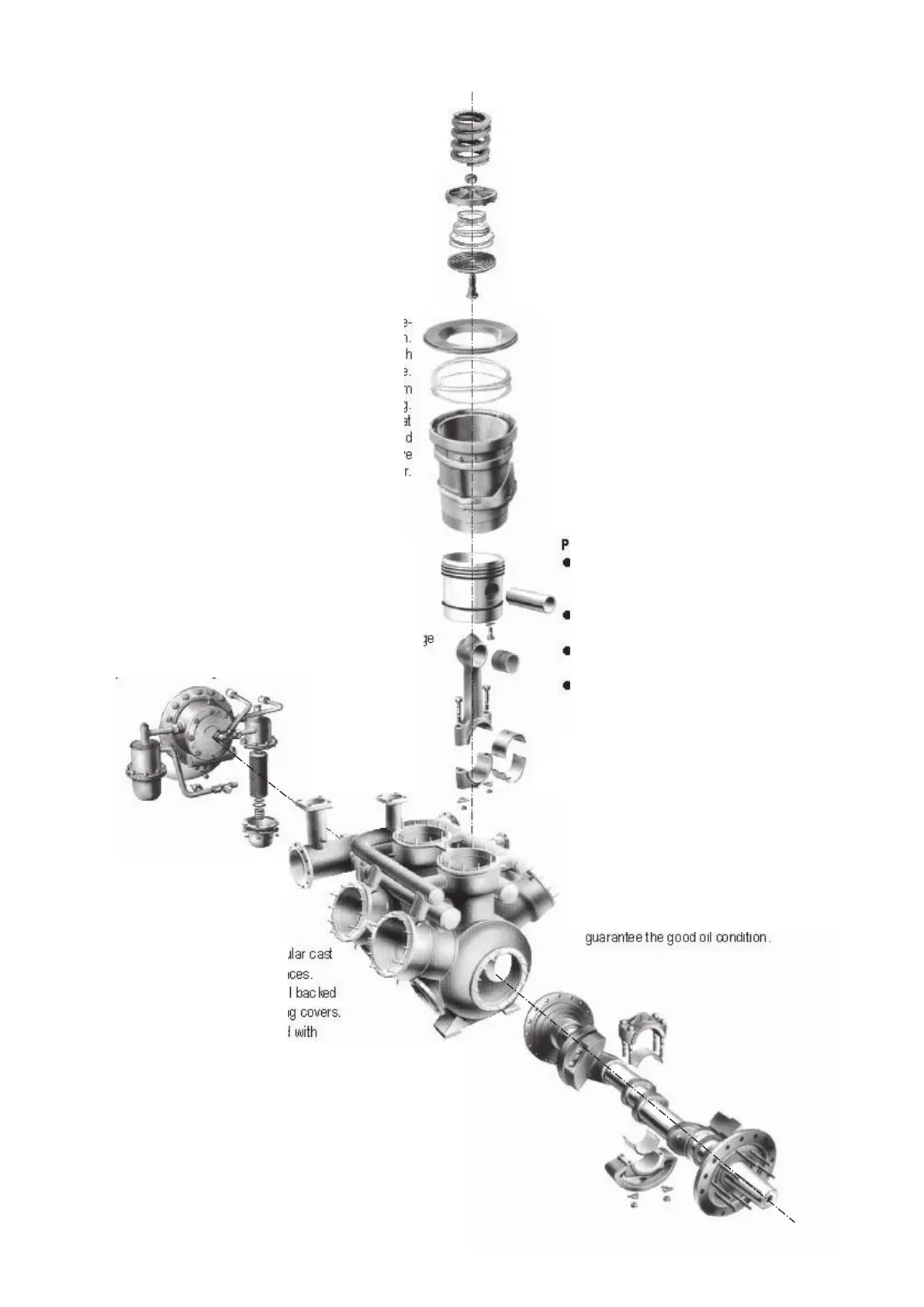

Welded Steel Crankcase

l Low in weight

l Rapid heat dissipation

l Gas tight and impact proof

l Smooth internal surfaces

guarantee the good oil condition.

Lubrication System & Filter

l Forced lubrication by a gear pump, driven directly by

the crankshaft.

l The pump incorporates a differential pressure regulator to

provide separate pressures for two oil systems: lubrication

system and control oil system.

l Automatically operating hydraulic delay valve ensures

complete unloaded start.

l A metal gauze suction filter element and a throwaway discharge

paper filter cartridges are provided for excellent filtering

capacity of the lubricating oil.

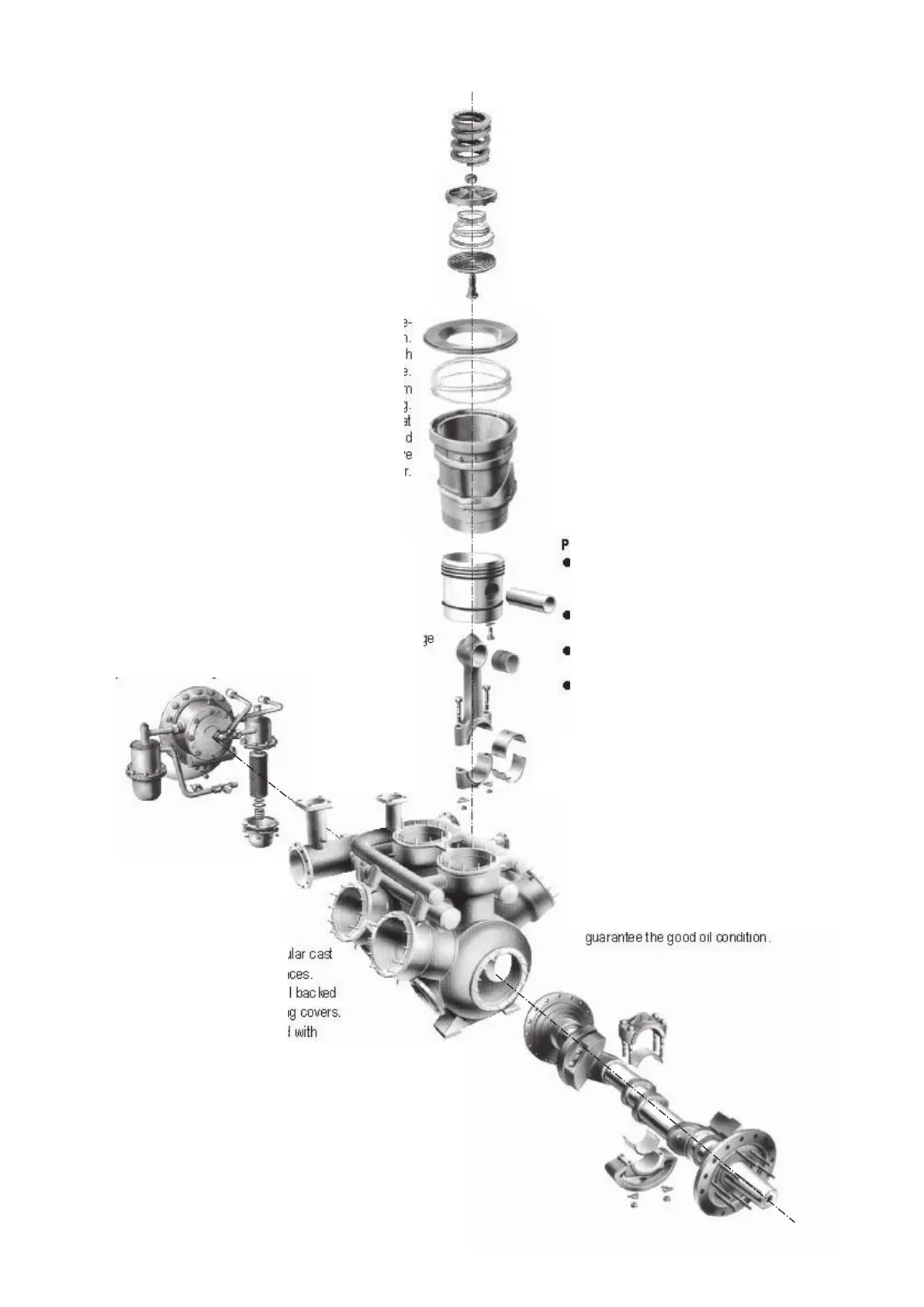

Discharge Valve Assembly

l Three concentric discharge valve rings ensure ample

gas passage at low lifting height.

l The use of sinusoidal springs together with precision

machined and lapped surface results in a trouble-free

operation for a remarkably long time.

l Minimum inventory for spares since most parts are

identical throughout the KC-series compressors.

Cylinder Liner and Suction Valve

l Interchangeable cylinder liners are made of fine-

grained, centrifugally cast, alloy iron.

l Fine boring and honing results in a mirror smooth

running surface.

l A hydraulic mechanical suction valve lifting mechanism

on each individual cylinder achieves loading and unloading.

l For unloading, the suction valve ring is lifted from its seat

in the cylinder collar by spring tension. Admitting controlled

oil pressure to the control piston, allowing the suction valve

ring to descend on its seat effects loading or cylinder.

Crankshaft and Main Bearings

l Bearing surfaces of the high quality nodular cast

iron crankshaft are ground to fine tolerances.

l Main bearings are white metal lined steel backed

bushes, pressed into the cast iron bearing covers.

Intermediate bearing blocks are provided with

split type bearing shell of the same type.

l Each crankshaft is dynamically balanced together

with the counter weights.

Salient Features of Construction

Piston/Connecting Rod Assembly

l Perfect sealing and low oil consumption due to

2 compression & 1-oil scrapper rings and 2 oil rings

on each aluminium piston.

l The nodular iron connecting rod is drilled through for

pressure lubrication of the piston pin

l Steel backed white metal shells on big end and

bronze bearing on small end of connecting rod.

l The complete assembly can be removed from the top

for servicing without withdrawing the cylinder liner

4

Loading...

Loading...