2.12 SAFETY VALVE

The compressor is fitted with one or more safety valves

depending on type of compressor. The safety valve is a spring-

loaded relief valve fitted between the delivery and suction

manifolds. At the time of excessive pressure in the delivery

manifold it by-passes gas back into the suction line. The

device can be easily removed for inspection or renewal.

The compressor should not be kept running with an open or

leaking safety valve as the machine would then become too

hot and the possibility of damage to, or even seizure of, the

piston and cylinder would arise. The line on the suction side of

the safety valve should be cold when the compressor is

operating. When it is found warm, the safety valve is leaking,

causing loss of capacity. In this case the safety valve must be

repaired or renewed.

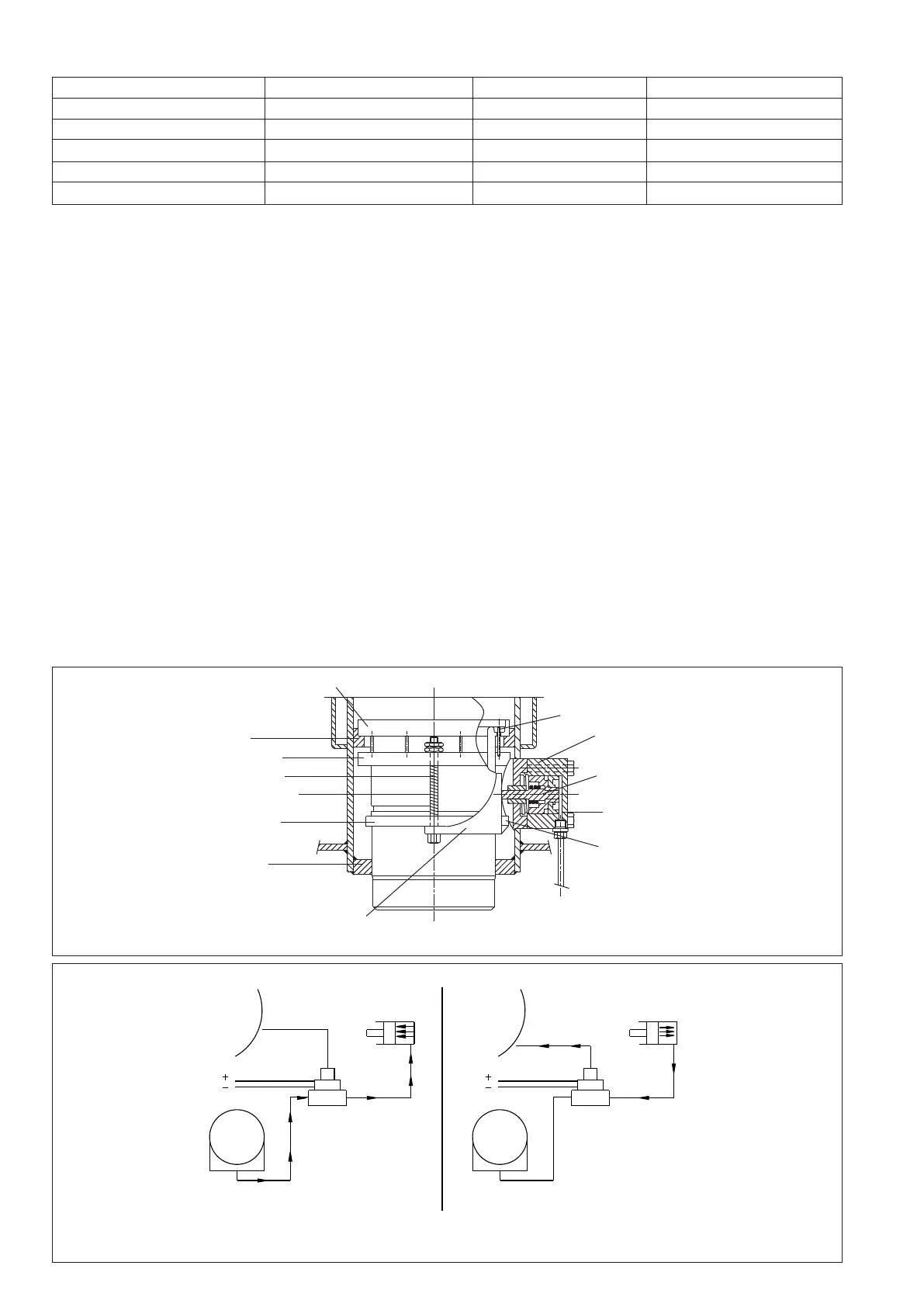

2.13 VALVE LIFTING MECHANISM -

Ref. Fig. 7 and 8

This mechanism can be subdivided into hydraulic and

mechanical components. The hydraulic assembly consists of

a piston housing with a teflon ring sealed piston controlled by

Figure 7 : Arrangement of Valve Lifting Mechanism

oil pressure. The mechanical assembly consists of a operating

ring to which are attached two actuating rods on its underside.

Eight valve lifting pins are located around the upper face of

the operating ring and the whole assembly is free to move in a

vertical direction.

The actuating rods pass through a supporting ring which is

rigidly held in a groove around the outside of the cylinder

liner. Pressure springs are fitted around each actuating rod,

tending to force the operating ring in an upward direction. To

the lower end of the actuating rods is attached a semicircular

lever, the fulcrum of which is fixed to the supporting ring. The

movement of this lever is controlled by the piston stem of the

hydraulic assembly bearing against its upper end.

In the "No-load" position the operating ring is in the upper

position, thus lifting the suction valve ring. When the

hydraulic piston is moved in towards the cylinder liner by the

high pressure oil it bears against the lever, causing the

actuating rods to be drawn down against the spring load. This

causes the valve lifting pins to be retracted thus enabling the

suction valve ring to descend on to its seat, thereby putting the

cylinder on load.

2.11 LUBRICATING CHART

Recommended Lubricants for Single Stage, Two Stage & Booster Compressors (ISO VG 68 Grade):

Sr. Brand Quality of Oil Suitable for Refrigerant Evaporation Temp. Range

01 Indian Oil (IOC) Servofriz-57/68 NH3, R12, R22 +10 to -25°C

02 Hindustan Petroleum (HP) SEETUL-68 NH3, R12, R22 +10 to -25°C

03 Bharat Petroleum (BP) Bharat Freezol-46/68 NH3, R12, 22 +10 to -25°C

04 Shell Clavus Oil-46/68 NH3, R12, R22 +10 to -25°C

05 Castrol Castrol Refrigeration Oil-46/68 NH3, R12, R22 +10 to -25°C

Note:

1. No two or more brands of oil to be mixed together for lubrication purposes.

2. Whenever you need to change brand of oil from earlier one, whole refrigeration system to be flushed with Nitrogen so that no traces of earlier oil exist in

refrigeration system.

3. When evaporating temperature is below (-)25°C suitable synthetic oil (ISO VG 68 grade) is to be used. (contact KPCL for details).

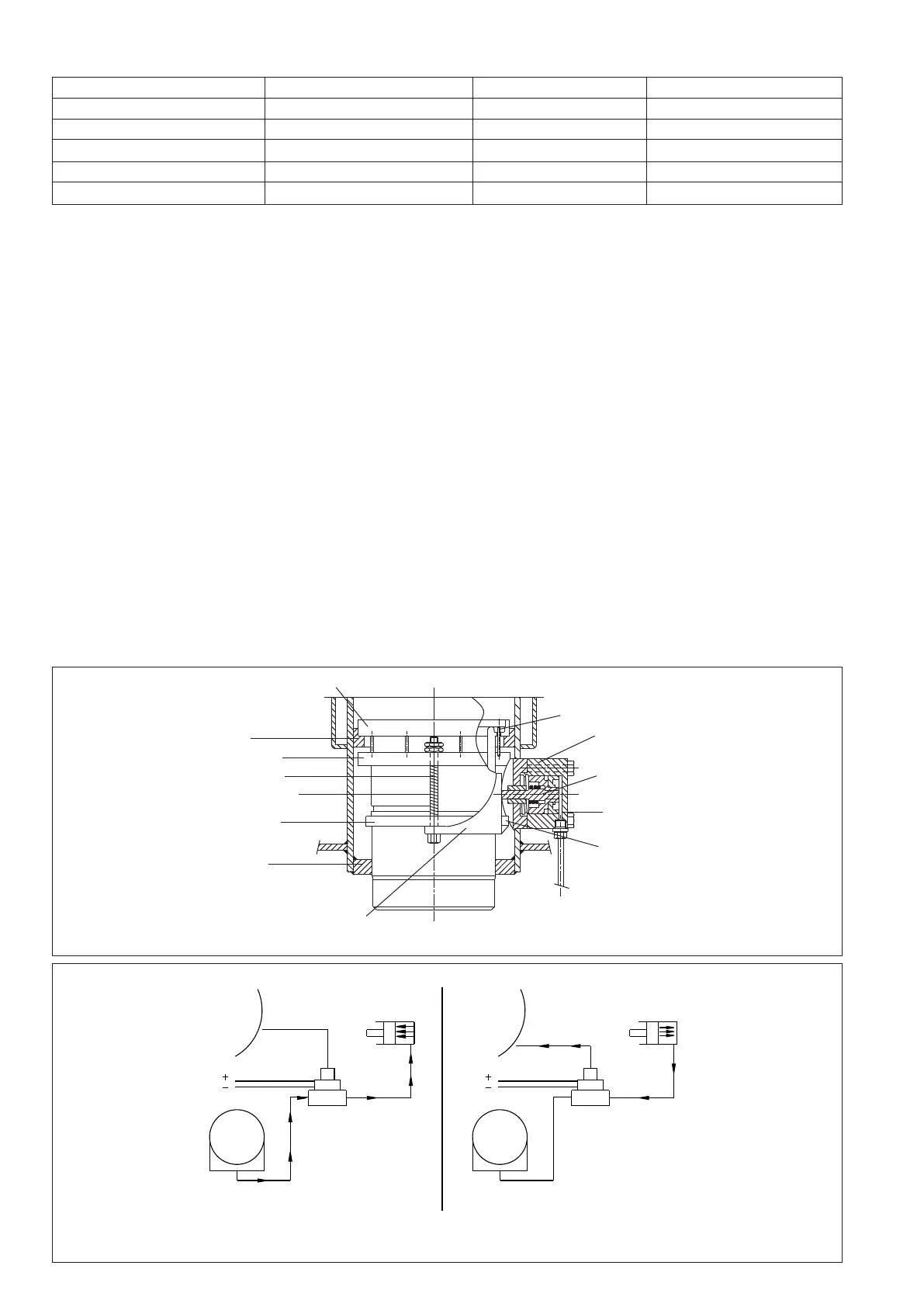

Figure 8 : Arrangement of Oil Control Piping for Loading-Unloading of Cylinders

UNLOADER PISTON ASSY.

(V L D PISTON ASSY)

COMPR.

CRANK

CASE

COMPR.

CRANK

CASE

UNLOADER PISTON ASSY.

(V L D PISTON ASSY)

220 V AC220 V AC

SOLENOID VALVE SOLENOID VALVE

1

3

2

1

3

2

OIL

PUMP

OIL

PUMP

SOLENOID VALVE ENERGIZED

COMPRESSOR CYLINDER ON LOAD

SOLENOID VALVE NON-ENERGIZED

COMPRESSOR CYLINDER UNLOADED

SUCTION VALVE RINGCYLINDER LINER

GASKET

PRESSING RING

TAP BOLT

ACTUATING ROD

PRESSURE SPRING

RING WITH

HINGED POINT

CRANKCASE

CYLINDER

VALVE LIFTING PIN

V L D PISTON

HOUSING

FULCRUM PIN

V L D PISTON ASSY.

OIL PASSAGE

SEMI CIRCULAR LEVER

FROM OIL DISTRIBUTOR OR

THREE WAY SOLENOID VALVE OR OIL PUMP

8

Loading...

Loading...