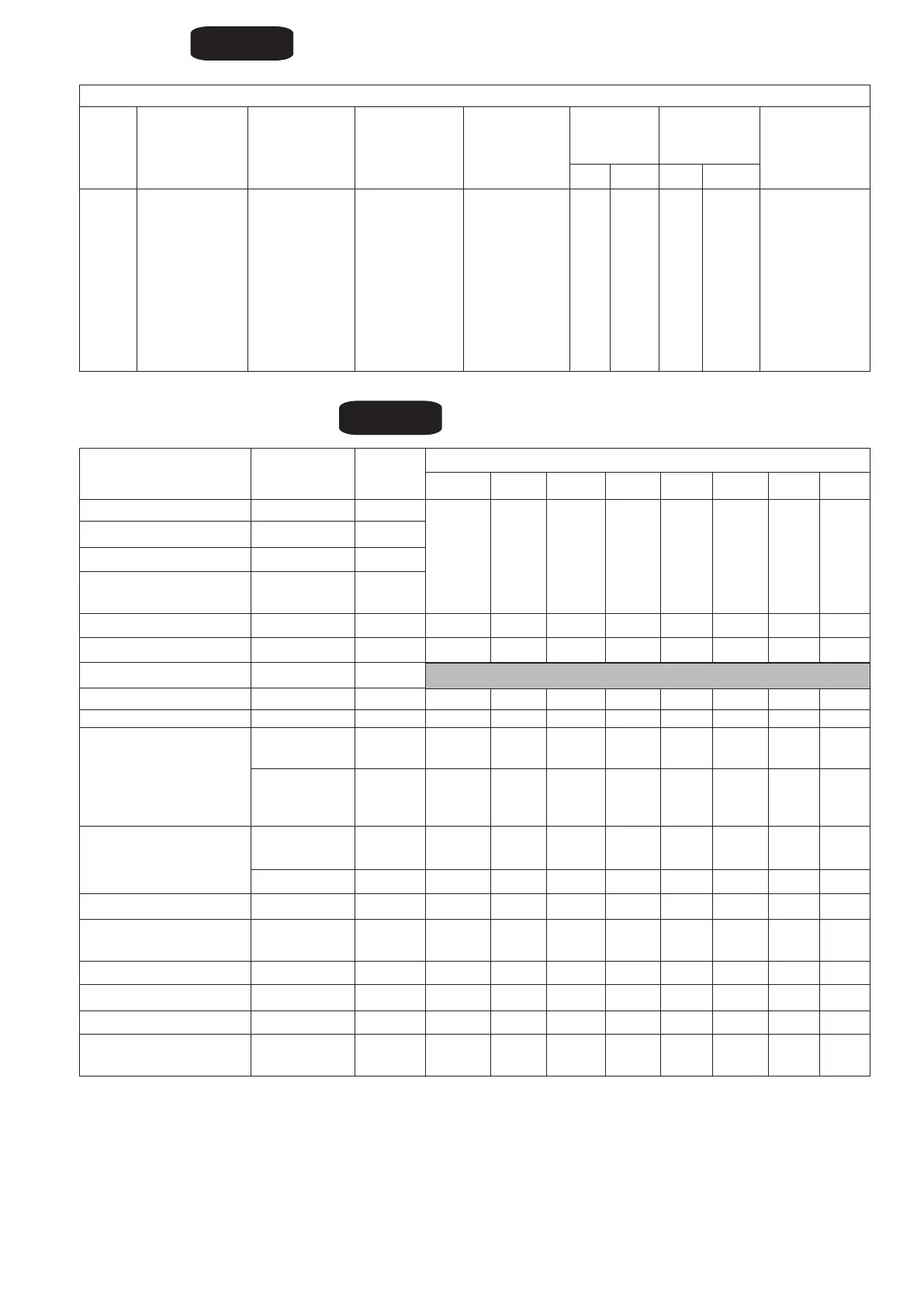

LOG SHEET

DATE: COMPRESSOR NO.:

TIME SUCTION DISCHARGE INTR TE OIL CHILLER COND'R OIL

HR. PRESSURE PRESSURE PRESSURE PRESSURE TEMP. PR. TEMP. PR. LEVEL

TEMPERATURE TEMPERATURE TEMPERATURE TEMPERATURE °C °C %

°C °C °C °C IN OUT IN OUT

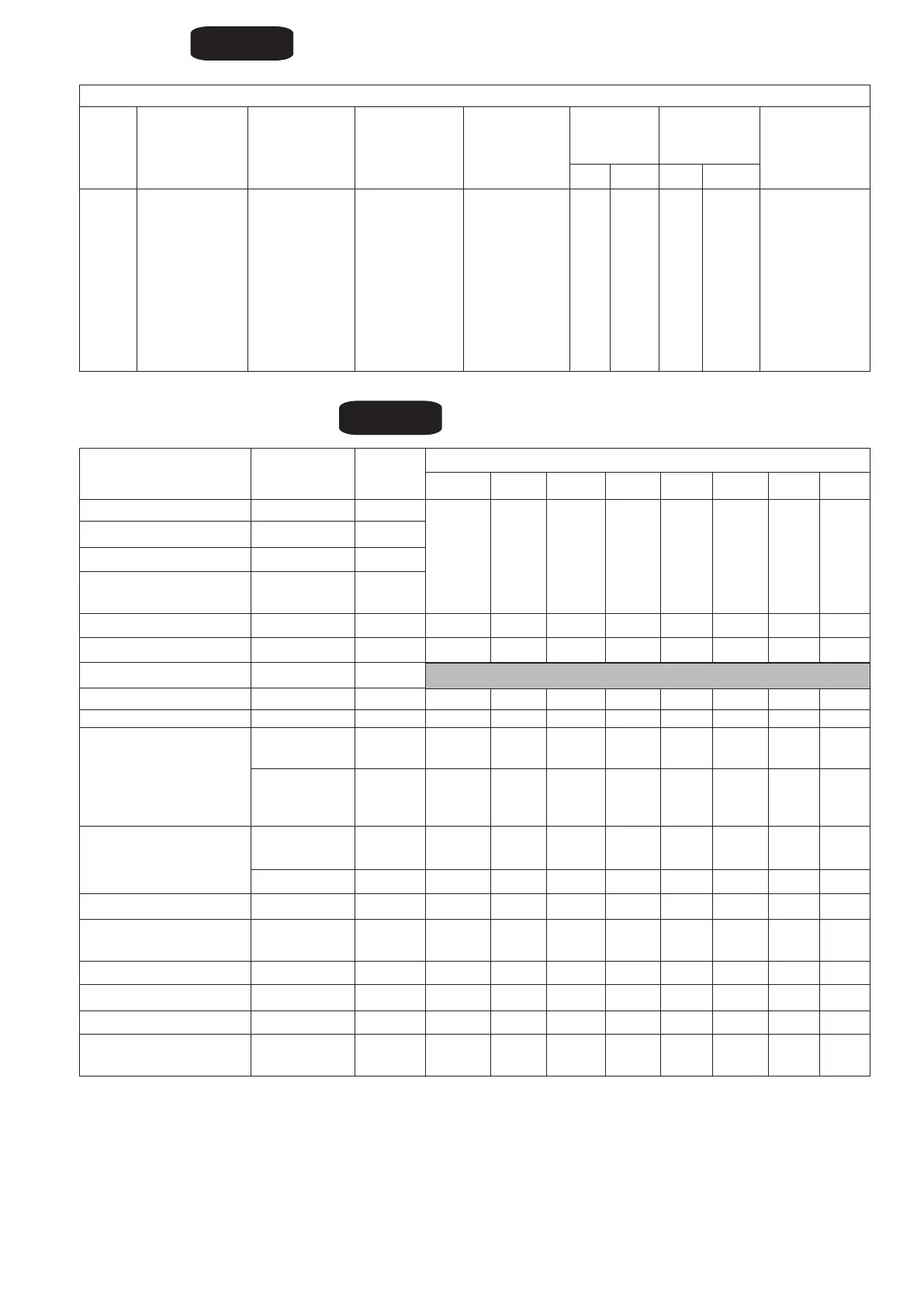

7.13 MAINTENANCE SCHEDULE:

Note: This maintenance schedule is based on one year span of operation (continuous).

It is necessary to inspect the compressor thoroughly every year irrespective of number of hours it has run.

Hourmeter should be installed during commissioning to record total hours of operation.

COMPONENT OF SYSTEM ACTION CHECK HOURS OF OPERATION

100 500 1500 3000 4500 6000 7500 9000

OIL LEVEL 4

OIL PRESSURE CHECK 4 DAILY

DISCHARGE PRESSURE AND 4

SUCTION PRESSURE AND RECORD

SUCTION GAS TEMP. 4

LUBRICATING OIL RENEW - 44444444

SUCTION OIL WIRE FILTER CLEAN - 44444444

DISCH. OIL PAPER FILTER RENEW - RENEW EVERY 500 HOUR

SUCTION GAS STRAINER CLEAN - - 4- 4- - 4-

OIL PUMP CLEAN - - - - - - - - -

DRIVE SYSTEM ALIGNMENT OF - 44- 4- 4- 4

COUPLING

CHECK & - 44- 4- 4- 4

ADJUST BELT

TENSION

SUCTION/DISCHARGE DISMANTLE & - - 4- - 4- - -

VALVES INSPECT

RENEW - - - - - - - - 4

SUCTION GAS STRAINER CLEAN - - 4444444

PISTON & PISTON RINGS INSPECT FOR - - - - - - 4- -

CLEARANCE

ALL BEARINGS INSPECT - - - - - - - - 4

SHAFT SEAL LEAKAGE INSPECT 44- - - 4- - 4

TIGHTNESS OF BOLTS INSPECT 4- 4- - 4- 44

TIGHTNESS OF INSPECT 44- - - 4- - 4

FOUNDATION BOLTS

IMPORTANT

IMPORTANT

25

Loading...

Loading...