21

(Continued on the following page)

Frequent Inspection

Check the Chain Hoist under the installation state or

on the workbench.

Check the following items in addition to the daily inspection items.

Before a frequent inspection, perform the daily inspection.

NOTE

Item Method Discard limit or criteria Action

Basic

function

Suspend a light load and lift/

lower it.

• Lifting operation should make regular click

sounds of the Pawl of the brake unit and

perform smoothly.

• Sounds should be at a constant level or no

irregular clicks should be heard.

• No sounds should be made when lowering.

• It should be free of any heavy pulling force.

• There should be no slip in braking.

Disassemble the Chain

Hoist to verify that

the hoist is properly

assembled and the

components are free of

defects.

Top and

Bottom

Hooks

Visual check • The hook should not be signicantly twisted

or deformed.

• Should be free of any deep notches of aws.

• Should be free of any loosened or omitted

rivets, bolts or nuts.

• Should be free of any foreign matter such as

sputter on the Hook.

Replace the Top Hook

Set or the Bottom Hook

Complete Set.

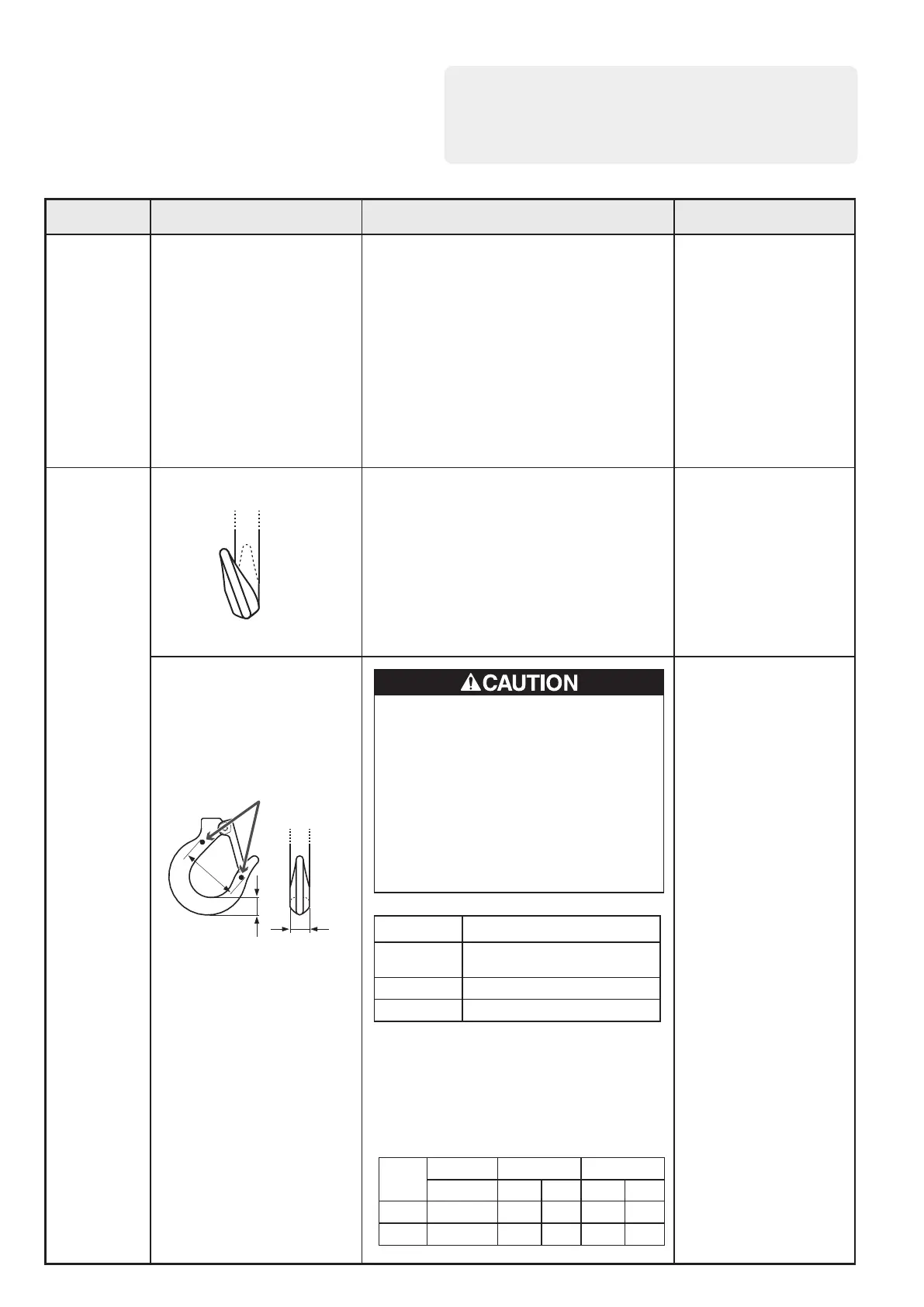

Measure the dimensions of

each "a", "b" and "c" of the

Top and Bottom Hooks using

calipers.

The nominal values are indicated

below for reference, however, the Hook

dimensions have tolerances to some

extent because it is forged and thermally

treated.

Replace the Top Hook

Set or the Bottom Hook

Complete Set.

Standard Limit

Dimension a

Not to exceed the dimension when

purchased

Dimension b 5% or more wear

Dimension c 5% or more wear

b

c

a

Embossed mark

Compare the deformation and

thickness of the Top and Bottom

Hooks with those of when

purchased to check they are not

beyond the criteria.

Using Hook with dimensions beyond the criterion

may result in injury or damage to property.

Rated

load (t)

Dimension a Dimension b Dimension c

Standard

Standard

Limit

Standard

Limit

0.25 39 11

10.5 12.5 11.9

0.5 45.5 12

11.4 15 14.3

Loading...

Loading...