48

Oil filling

9

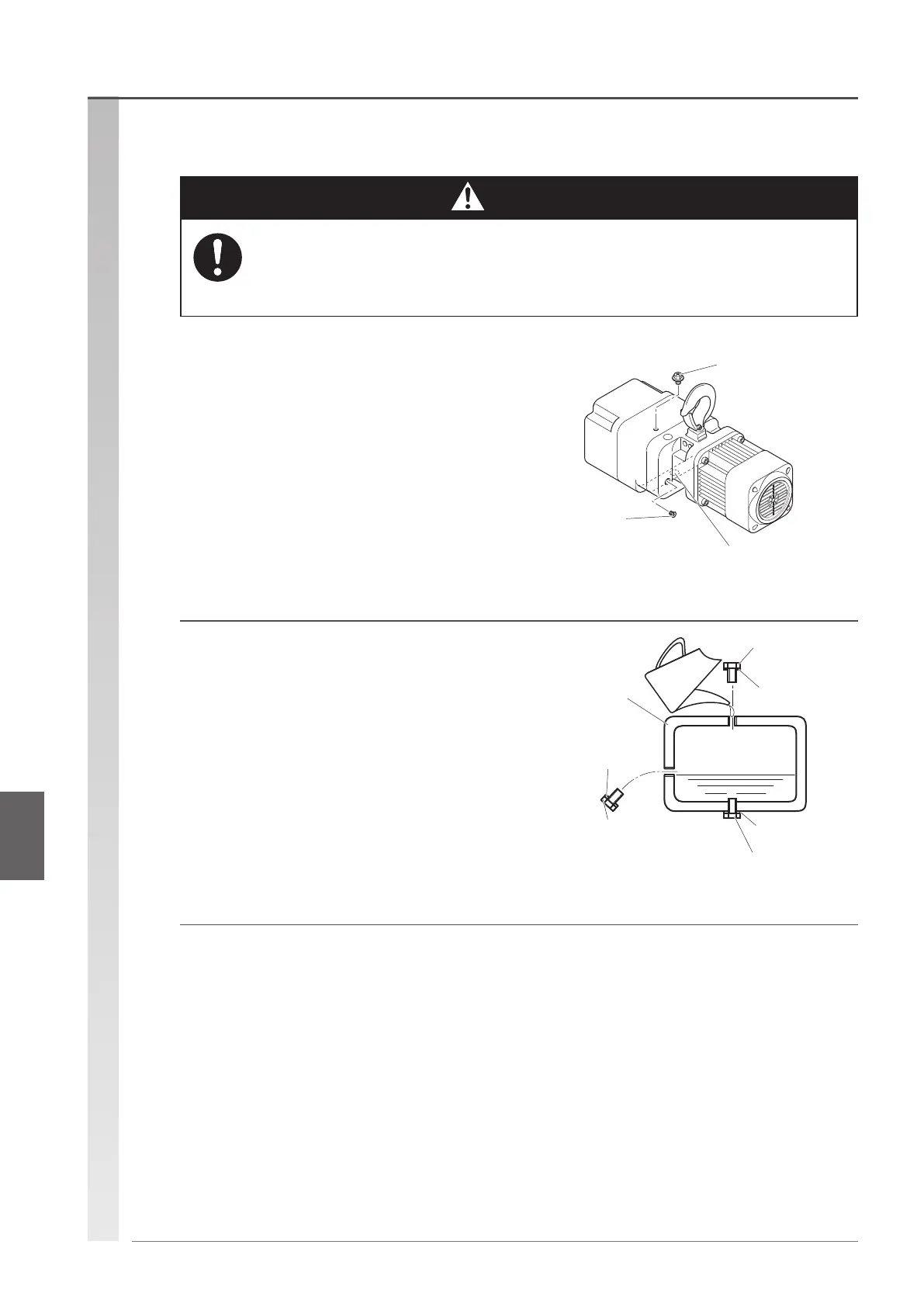

(1) Tighten the oil plug (for waste oil hole) with

a new packing securely.

Oil plug

(for waste oil hole)

Oil plug

(for oil check window)

OIL plug B

(for oilhole)

• Use genuine gear oil.

If you inject (or mix) any oil other than genuine oil, a major accident such as death or

serious injury may occur due to a dropped load.

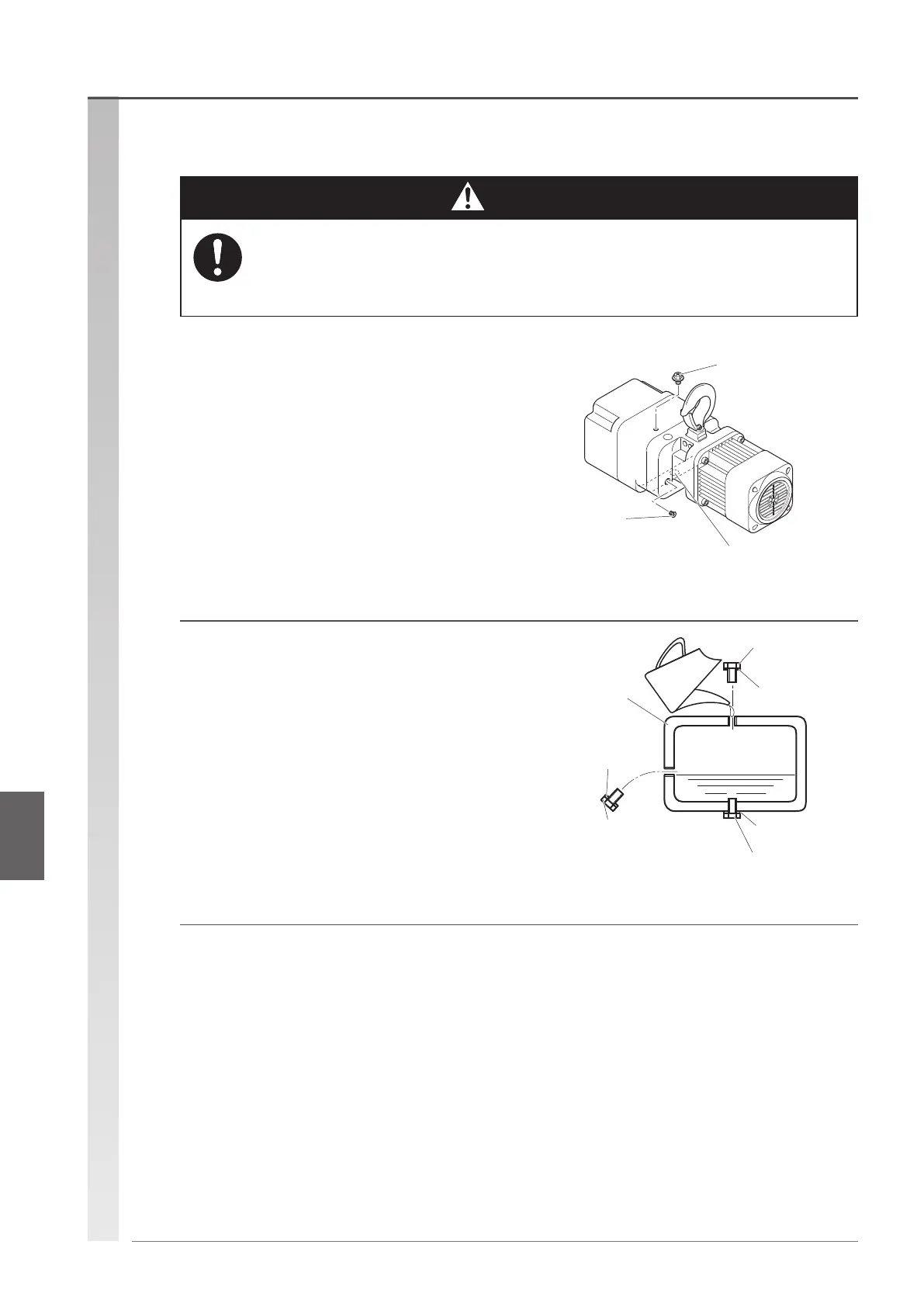

(2) Inject gear oil from the oil plug B

(for oilhole).

•

Inject a proper quantity of oil by referring to the table on

the next page.

Inject oil up to the proximity of the oil plug (for oil check

window).

(3) Place a new packing on the oil plug B (for

oilhole) and tighten it.

Use Kito genuine gear oil. (Refer to the oil

quantity on the next page.)

* The friction clutch with mechanical brake specification has a

sticker that indicates “With mechanical brake" (orange letters

on a black background) to the right side seen from the main

body controller cover.

Packing

Packing

Packing

Oil plug B

(for oilhole)

Main body

Oil plug

(for waste oil hole)

Oil plug

(for oil check window)

Gear oil

Mandatory

Danger

Reassembly procedure (continued)

Reassembly procedureOillling

Loading...

Loading...