47

5.3 ROUTINE CHECKS

In addion to the required Periodic Checks to be performed by service centres authorised by the manufacturer, you should

carry out certain simple preventave checks to ensure safe reliable plaorm operaon.

NOTE!! To benet from the plaorm warranty, the informaon given in this maintenance schedule must be followed exactly.

A . DAILY INSPECTIONS

Every day a visual inspecon of the plaorm is necessary to detect any problems before they become serious. Special

aenon must be given to the following details:

1) Welds: All welds must be examined for signs of fague. Emerging cracks in a weld are a serious sign of weld fague. A

few crical welds can be found in the turret area and these call for special aenon. Inspect carefully where the anges

of the turrets are welded to the base, where the cylinder armatures are welded to the boom and the cylinder armatures

are welded to the turret together with the plaorm support welds.

2) Cracks/Damage to Structural Parts of the Plaorm: All structural parts must be checked for cracks or damage; if found

the machine should not be used.

3) Emergency Motor: Operate the electric emergency motor for 30 seconds to ensure operaon

4) Hydraulics: Check for the following

• Hydraulic leaks - revealed by hydraulic oil spillage under the vehicle, on the oor or under the mast.

• Hydraulic pipes - check for cracks, wear and any other damage

• Hydraulic oil - check the hydraulic oil level

5) Basket: Check that the basket is free of damage or cracking on the sides or in the boom. If there is a problem, have the

bucket repaired by a qualied repairer before use.

6) Tyres: Check that the basket is free of damage or cracking on the sides or in the boom. If there is a problem, have the

bucket repaired by a qualied repairer before use.

7) Air Bags: Check air bags are inated correctly.

8) Electric Cables: Check that there is no damage to the protecve sheathing.

9) Outrigger Plates: Check that they are free of damage.

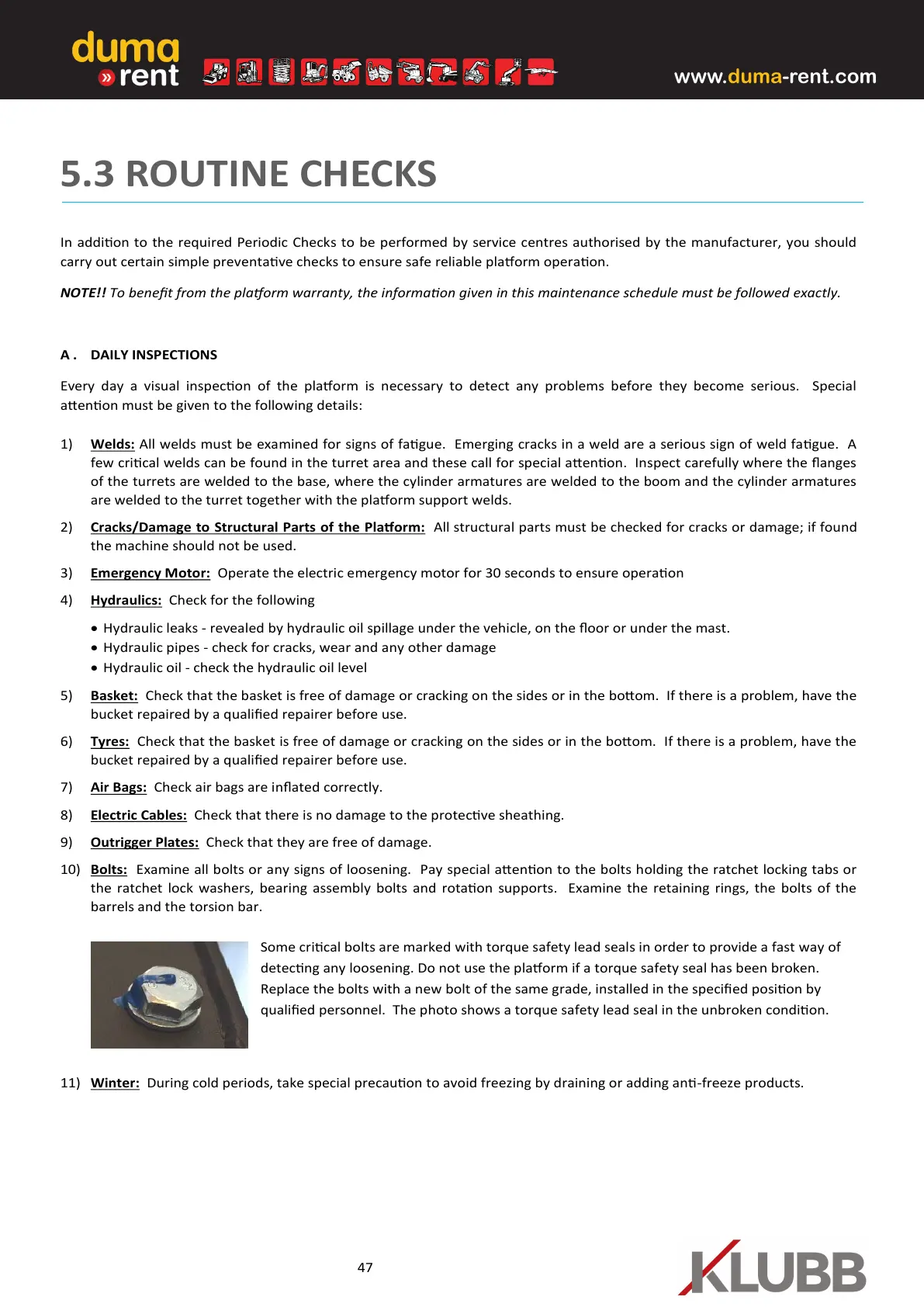

10) Bolts: Examine all bolts or any signs of loosening. Pay special aenon to the bolts holding the ratchet locking tabs or

the ratchet lock washers, bearing assembly bolts and rotaon supports. Examine the retaining rings, the bolts of the

barrels and the torsion bar.

11) Winter: During cold periods, take special precauon to avoid freezing by draining or adding an-freeze products.

Some crical bolts are marked with torque safety lead seals in order to provide a fast way of

detecng any loosening. Do not use the plaorm if a torque safety seal has been broken.

Replace the bolts with a new bolt of the same grade, installed in the specied posion by

qualied personnel. The photo shows a torque safety lead seal in the unbroken condion.

Loading...

Loading...