50

5.4 REGULAR MAINTENANCE CHECKS

Various kinds of adjustments may be necessary during normal machine use and, therefore, these operaons come under

regular maintenance acvity.

HOSING

Checking Condion

Check the seam fastening the ng to the hose and the condion of the hose.

If the hose shows signs of ageing, breakages, swellings, abrasions etc., it must be replaced.

Check that there are no oil leaks. Oil leaking out from a very small hole can be almost invisible

but can create a jet strong enough to pierce skin. When looking for oil leaks, use a piece of

card or wood.

Check the condion of the rigid hydraulic pipelines too.

Replacement

NOTE!! The hosing must be replaced with the hydraulic system depressurised.

To depressurise the system, disconnect the PTO, stop the truck engine, and move the

control levers both ways.

Unscrew the ngs, collecng the oil in a suitable container.

Replace the hose and ghten ngs.

CHECKING FOR OIL LEAKS FROM FITTINGS

Oil leaks from the ngs can normally be stopped by ghtening the ngs correctly.

Oil leaks from the ngs (A) equipped with gaskets can only be stopped by replacing the

ng.

CHECKING HOSING GUARDS

These guards protect the operator against potenal oil spurts in the event of hose breakage. If worn or broken,

they must be replaced.

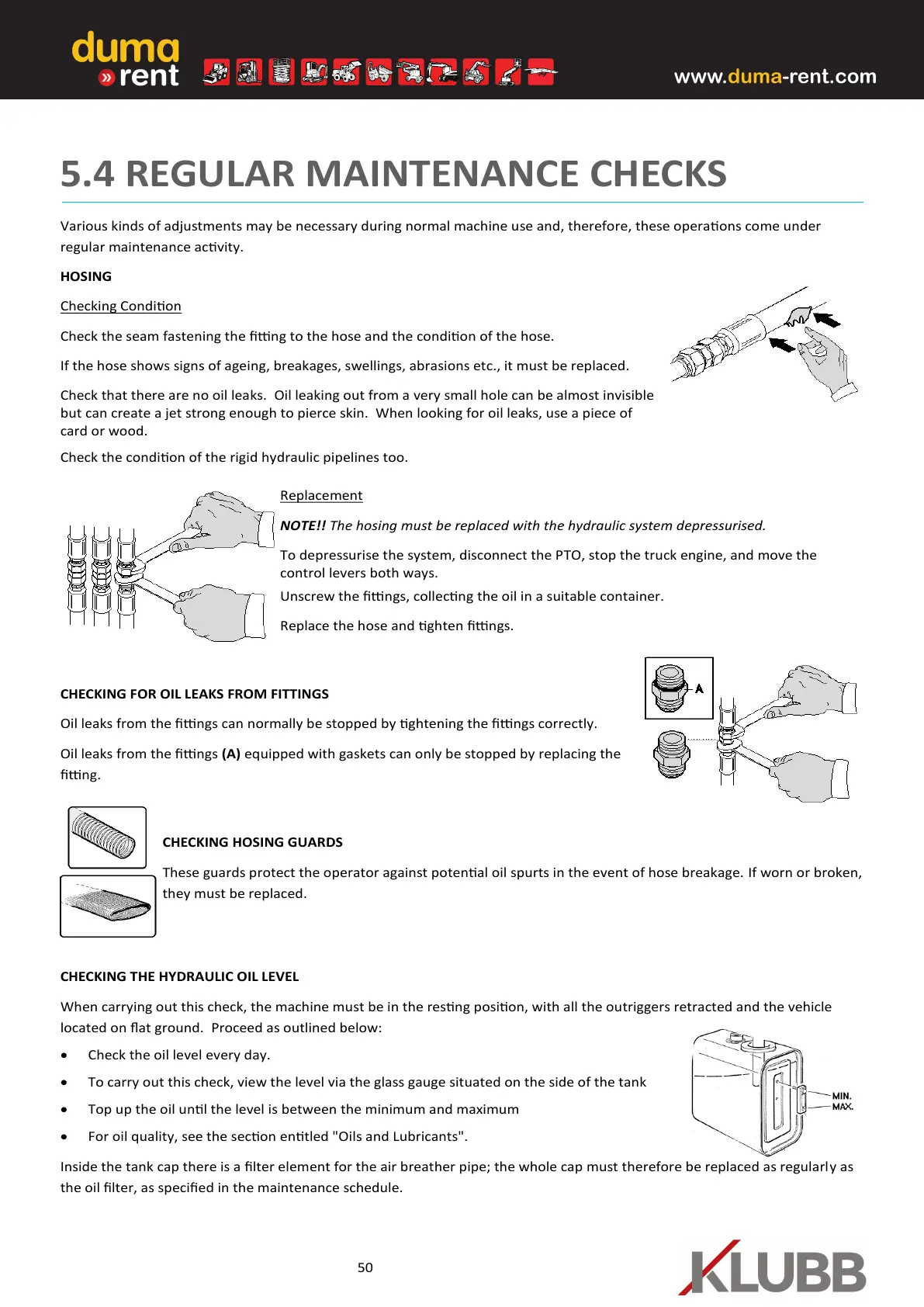

CHECKING THE HYDRAULIC OIL LEVEL

When carrying out this check, the machine must be in the resng posion, with all the outriggers retracted and the vehicle

located on at ground. Proceed as outlined below:

• Check the oil level every day.

• To carry out this check, view the level via the glass gauge situated on the side of the tank

• Top up the oil unl the level is between the minimum and maximum

• For oil quality, see the secon entled "Oils and Lubricants".

Inside the tank cap there is a lter element for the air breather pipe; the whole cap must therefore be replaced as regularly as

the oil lter, as specied in the maintenance schedule.

Loading...

Loading...