19

2.5 SAFETY DEVICES

On no account must you tamper with the safety devices. Use of the machine is forbidden if the seals have

been removed.

Locking Devices/Pin Retainers

The hinge and stop pins on the mechanical part (outriggers, arms, etc.) and the

hydraulic parts (outriggers) are provided with locking devices to prevent them sliding

out.

Lock Valve

Posioned on each jack, these valves prevent the outrigger moving in the event

that a hose bursts or there is a drop in the hydraulic system pressure.

Pressure Valves

Located on all the hydraulic distribuon units. To prevent overloading, these relieve operang pressure

when it exceeds the maximum set-point. The valves are set and sealed by the manufacturer during

tesng and must not be altered.

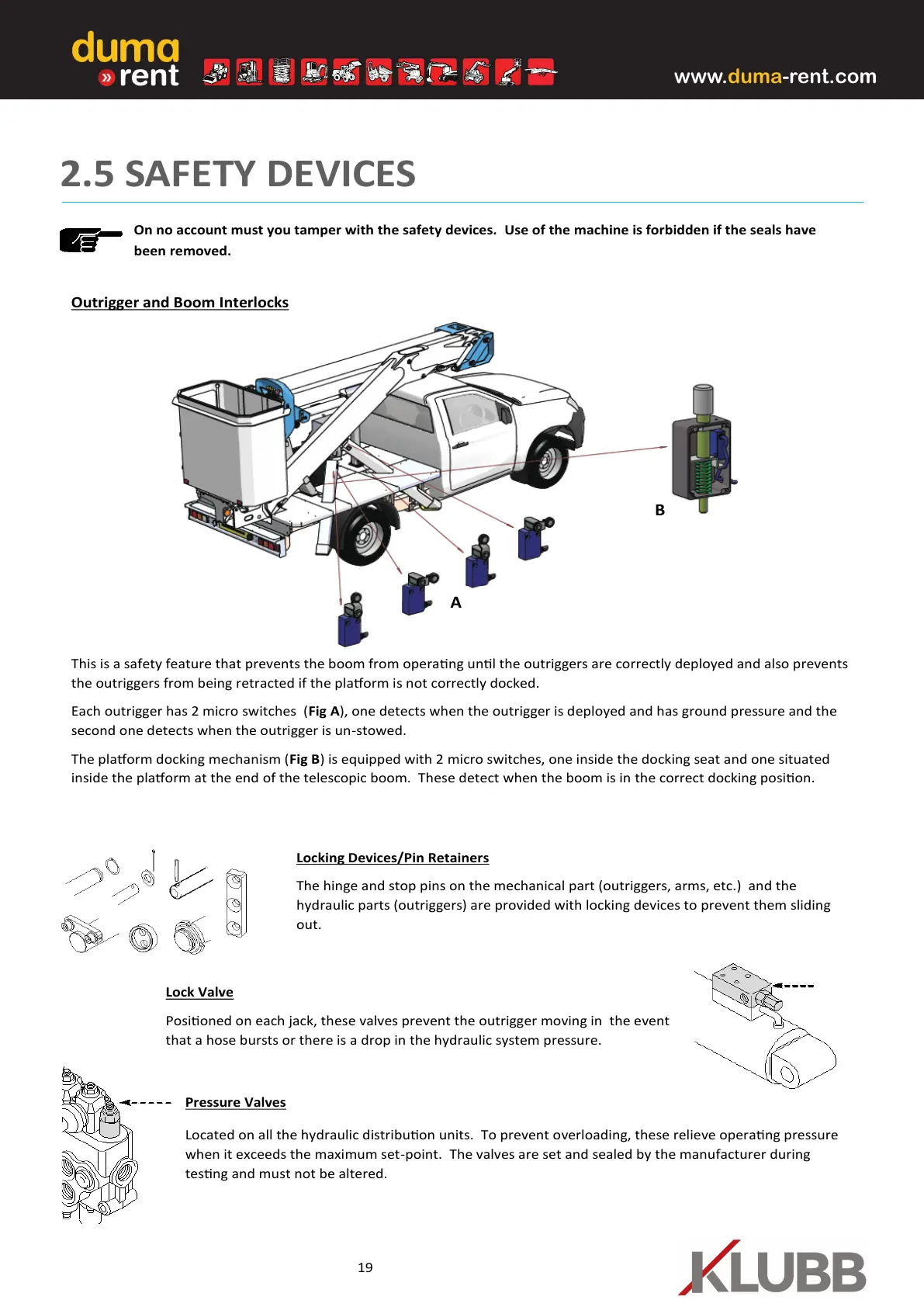

B

A

This is a safety feature that prevents the boom from operang unl the outriggers are correctly deployed and also prevents

the outriggers from being retracted if the plaorm is not correctly docked.

Each outrigger has 2 micro switches (Fig A), one detects when the outrigger is deployed and has ground pressure and the

second one detects when the outrigger is un-stowed.

The plaorm docking mechanism (Fig B) is equipped with 2 micro switches, one inside the docking seat and one situated

inside the plaorm at the end of the telescopic boom. These detect when the boom is in the correct docking posion.

Outrigger and Boom Interlocks

Loading...

Loading...