TP-6844 1/13 Section 5 Component Testing and Adjustment 69

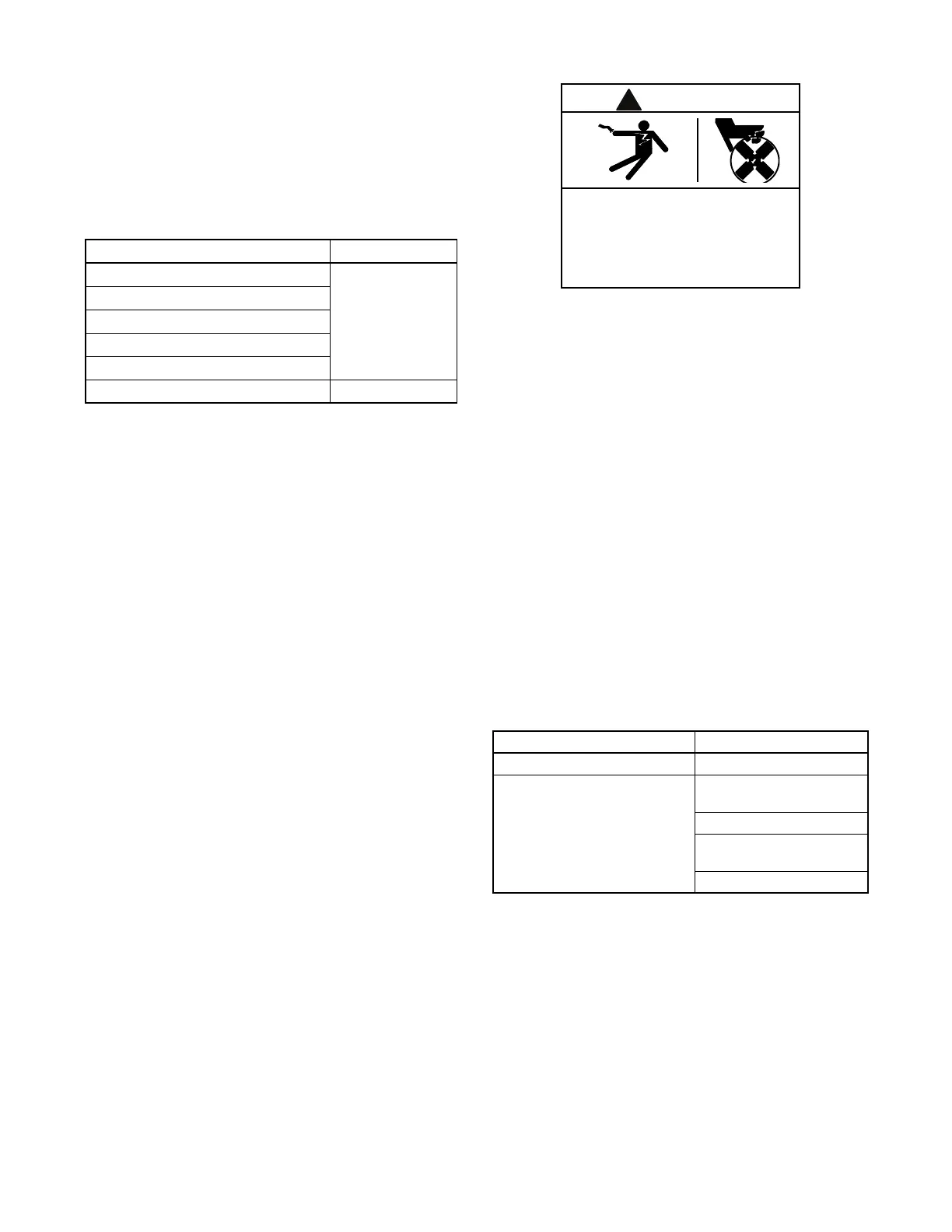

7. Check the cold resistance of the stator windings

by connecting the meter leads to stator leads 1-2,

2-3, and 3-1. See Section 1.5, Alternator

Specifications, for stator winding resistances.

Most ohmmeters do not provide accurate

readings below 1 ohm. Low resistance readings

(continuity) and no evidence of shorted windings

(heat discoloration) indicate a stator in good

condition. See Figure 5-10.

Figure 5-10

Figure 5-10 Continuity Test Results on a Good Stator

8. If the resistance test proves inconclusive, use a

megohmmeter to test the stator as described in

the next step.

Note: Because ohmmeter accuracy varies, resistance

readings are approximate readings. Take

readings of the rotor and stator at room

temperature.

Note: Make sure that all stator leads are disconnected

before running the megohmmeter test.

9. Use a megohmmeter to determine whether the

stator is shorted to ground.

a. Apply 500 volts DC to any stator lead and the

stator frame. Perform the megohmmeter test

following the instructions of the megohmmeter

manufacturer.

b. Repeat the test on the other stator leads until

each coil is tested.

Note: A reading of approximately 500 kOhms

(1/2 megohm) and higher indicates a good

stator.

c. Repair or replace the stator if any reading is

less than approximately 500 kOhms. A

reading of less than 500 kOhms indicates

deterioration of the winding insulation and

possible current flow to ground.

5.5 Voltage Adjustments

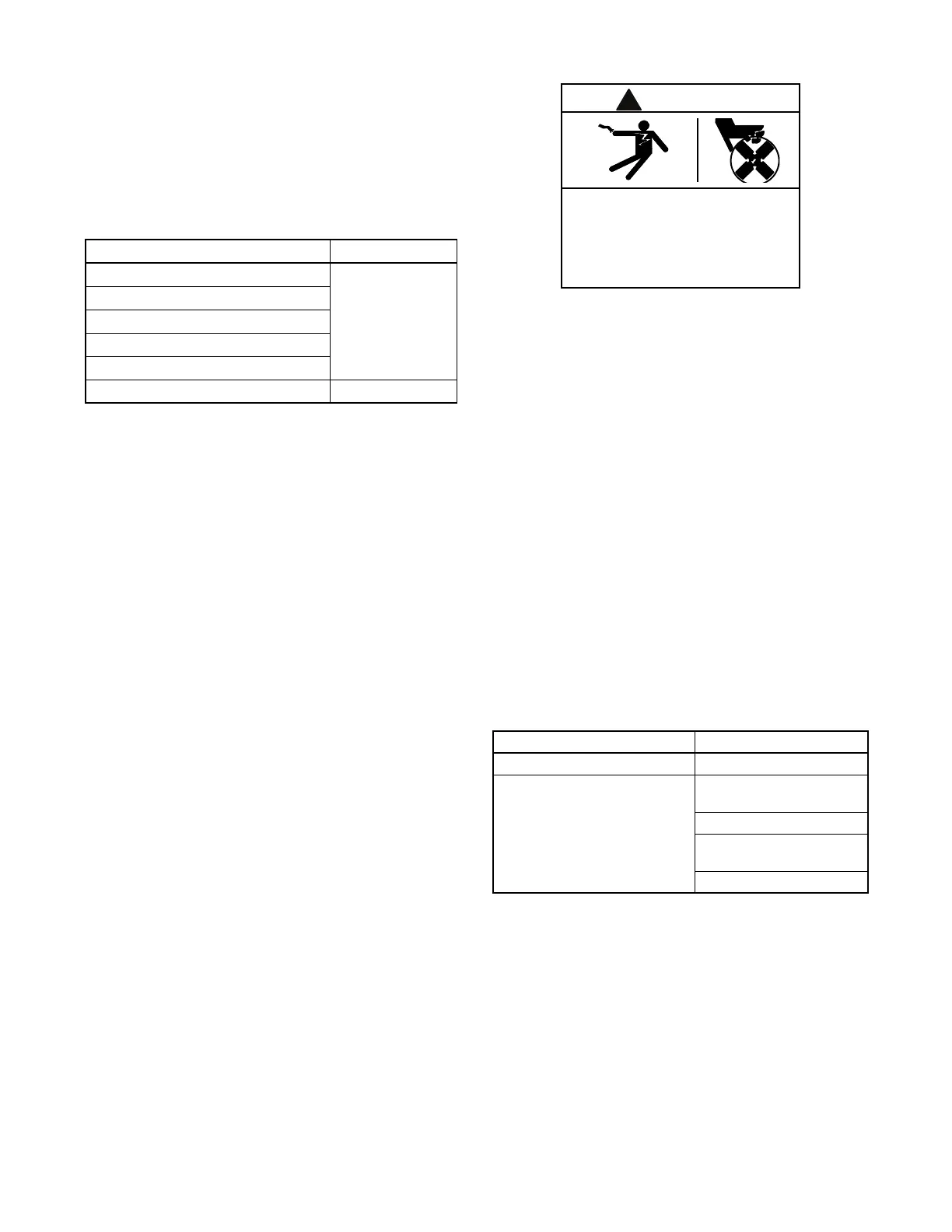

Testing live electrical circuits. Hazardous voltage or

current can cause severe injury or death. Have trained

and qualified personnel take diagnostic measurements of

live circuits. Use adequately rated test equipment with

electrically insulated probes and follow the instructions of the

test equipment manufacturer when performing voltage tests.

Observe the following precautions when performing voltage

tests: (1) Remove all jewelry. (2) Stand on a dry, approved

electrically insulated mat. (3) Do not touch the enclosure or

components inside the enclosure. (4) Be prepared for the

system to operate automatically. (600 volts and under)

Short circuits. Hazardous voltage/current can cause

severe injury or death. Short circuits can cause bodily

injury and/or equipment damage. Do not contact electrical

connections with tools or jewelry while making adjustments

or repairs. Remove all jewelry before servicing the

equipment.

Note: See Section 3.7 for voltage calibration

instructions.

Voltage Adjustments Using SiteTech

The SiteTech parameters used to adjust the voltage

are shown in Figure 5-11.

Figure 5-11

Figure 5-11 SiteTech Parameters for Voltage

5.5.1 Voltage Regulator Average Voltage

Adjustment

Voltage regulation is performed by the controller. The

controller monitors generator output voltage and

adjusts the Voltage Correction Factor to change the

operating speed range of the generator. The 6VSG

requires no adjustment to maintain rated output

voltage, as the DC output voltage is corrected to the

Voltage Regulator Average Voltage Adjustment as the

generator runs.

Leads Continuity

1 and 2, 2 and 3, 3 and 1

Yes

4 and 5, 5 and 6, 6 and 4

1 and 4, 2 and 5, 3 and 6

1 and 5, 2 and 6, 3 and 4

1 and 6, 2 and 4, 3 and 5

1, 2, 3, 4, 5, or 6 to ground No

Hazardous voltage. Moving parts.

Can cause severe injury or death.

Operate the generator set only when

all guards and electrical enclosures

are in place.

SiteTech Group Parameter

Genset System Configuration Genset System Voltage

Voltage Regulator Average Voltage

Adjustment

Volts per Hertz Slope

Volts per Hertz Cut-in

Frequency

Voltage Regulator Gain

Loading...

Loading...