TP-6844 1/13 Section 5 Component Testing and Adjustment 79

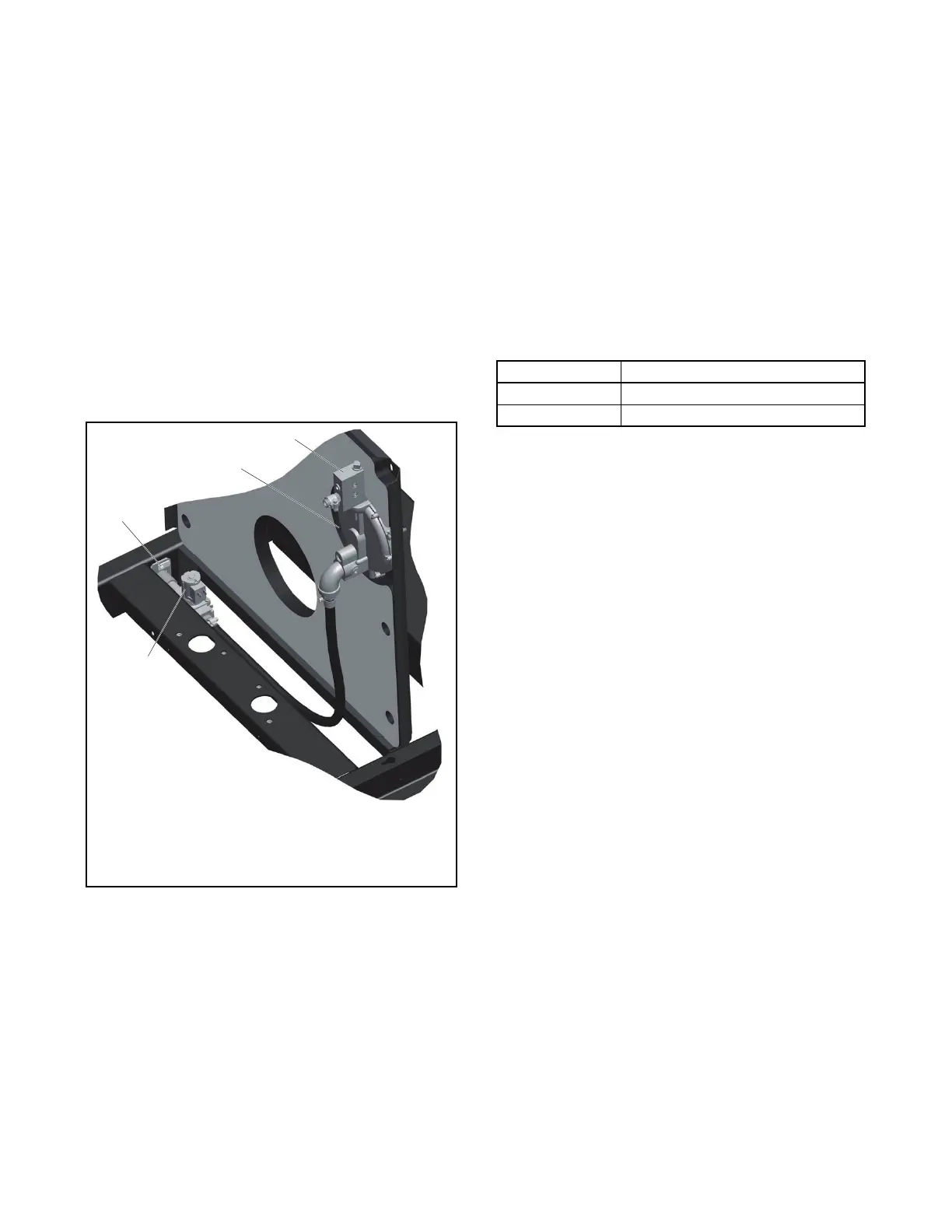

5.8.1 Fuel Solenoid Valve

A solenoid valve upstream of the regulator and the

flexible fuel connector provides automatic fuel on/off

control. See Figure 5-23. The engine starting battery

powers the solenoid valve and the engine starting

controls open the valve when the engine cranks or

runs.

Fuel Valve Operation Test Procedure

1. Disconnect the positive (+) battery lead from the

gas valve terminal.

2. Apply 12 VDC to the gas valve terminal and listen

for an audible click, indicating that the valve

actuates.

3. Replace the gas valve if it does not actuate in

step 2.

Figure 5-23

Figure 5-23 Fuel System

5.8.2 Fuel Regulators

The typical gaseous fuel system uses two regulators.

The primary regulator reduces the line pressure to an

allowable inlet pressure for the secondary regulator.

The fuel supplier provides and maintains the primary

regulator. The secondary regulator is factory-installed

on the generator set and is designed for a maximum

inlet pressure of 2.7 kPa (6 oz./in.

2

) or 280 mm (11 in.)

water column.

Note: Do not attempt to adjust the fuel mixture or

engine speed by adjusting the regulators.

The fuel lockoff prevents fuel flow when the engine is

not operating. See Figure 5-25. Do not try to adjust

the fuel pressure, fuel mixture, or engine speed using

the fuel lockoff.

Checking the Fuel Pressure

Use a gauge or manometer to check the fuel pressure

at the secondary regulator inlet. See Figure 5-25.

Measure the fuel pressure with the generator set

running at rated load. Contact the fuel supplier if the

inlet pressure is not within the range shown in

Figure 5-24.

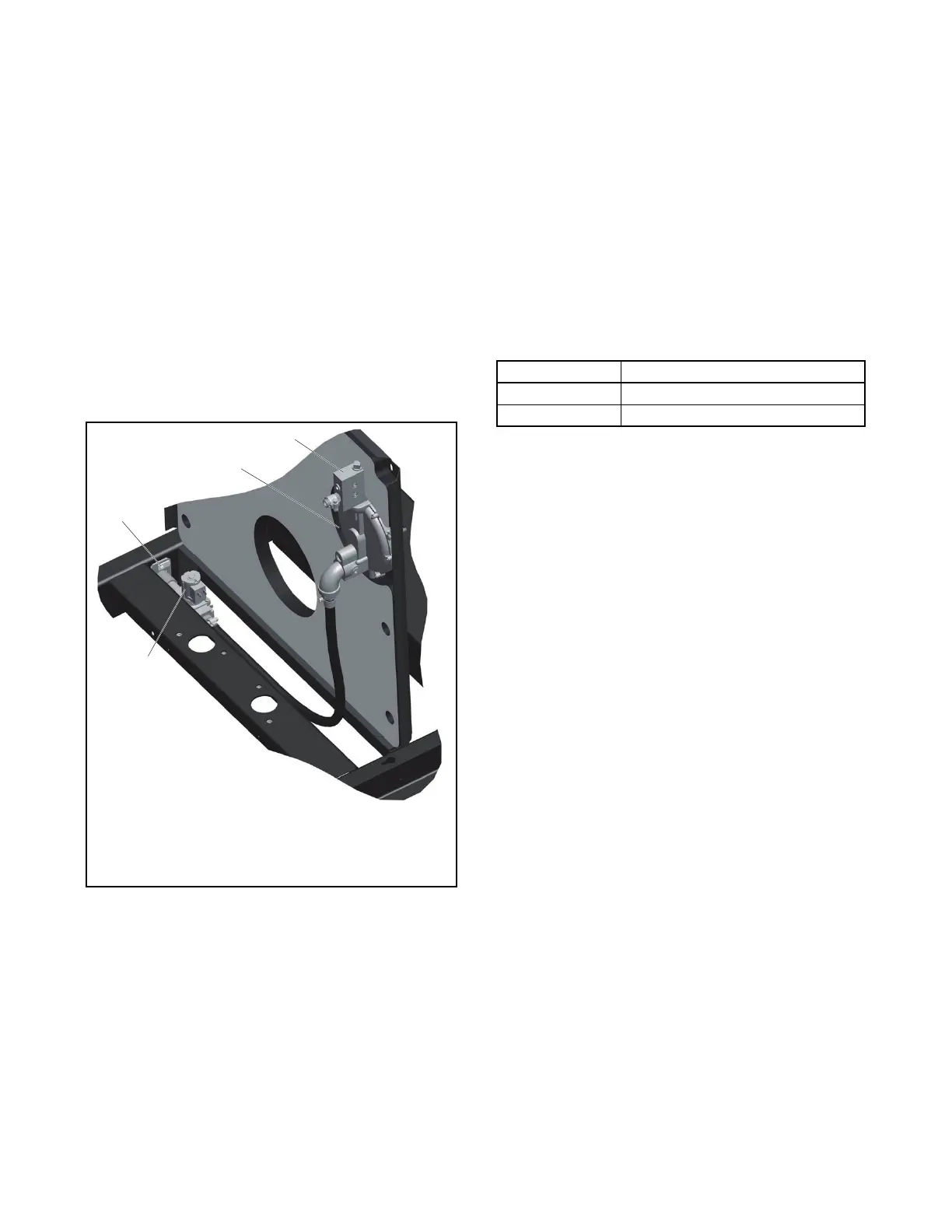

Figure 5-24

Figure 5-24 Fuel Pressure Requirements

1. Regulator

2. Fuel block

3. Fuel solenoid valve

4. Fuel inlet, 1/2 in. NPT

female

Fuel Fuel Pressure Required

Natural Gas 1.2–2.7 kPa (5–11 inches H

2

O)

LPG 1.7–2.7 kPa (7–11 inches H

2

O)

Loading...

Loading...