M-SS-017-07 Rev C 10 SERVOSTAR CD

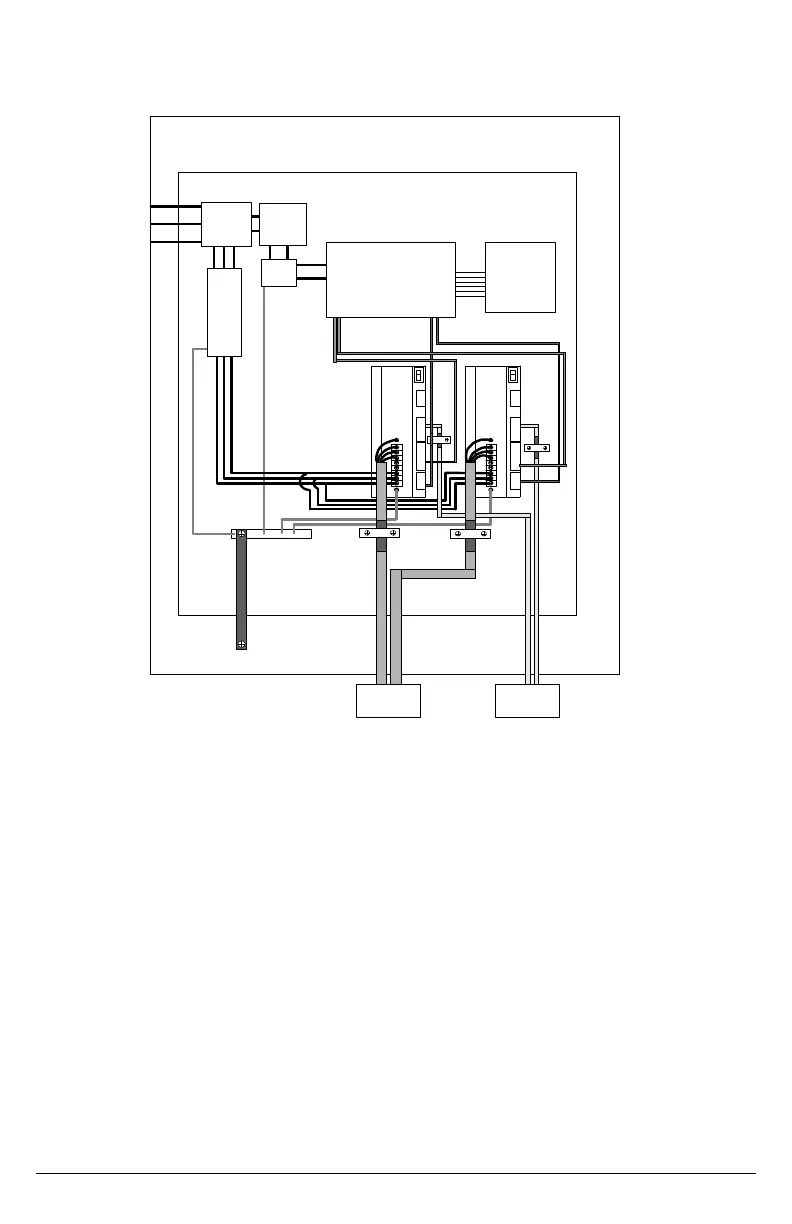

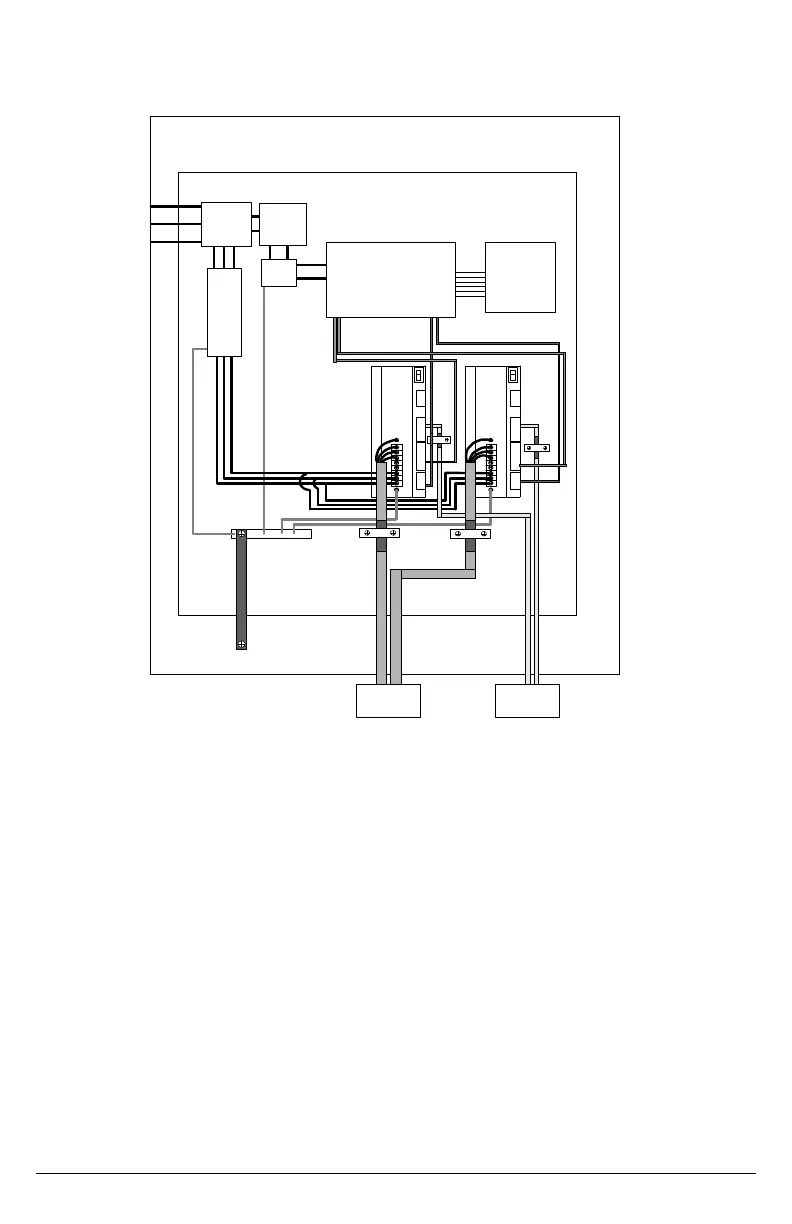

CX FILTER AND BONDING DIAGRAM

Cabinet/Enclosure

CDCD

Routed to

Motors

Controller I/O

Routed to

Motors

Contactor,

Fuses,

Xfmr,

etc.

230

VAC

XFMR

CNC / PLC / Controller

EMI

filter

EMI

filter

Back Plane

2

3

4

5

6

7

8

9

1

Note 1

Input power enters enclosure from metal conduit. This

eliminates the need for shielded input power cable.

Note 2

Single point ground. A bus bar (ground bus) is an

excellent way to achieve this.

Note 3

High frequency ground between non-conductive back

panel and enclosure. Also, a high frequency ground is

required between the enclosure and earth ground.

Note 4

EMI filter grounding. Safety grounds must be provided

on the filters. Hazard potentials exist even when the

power is off because of the capacitors internal to the

filters.

Note 5

Bonding of motor cables. The use of armored

(screened) motor cables bonded as close to the drive

as possible are essential for CE compliance and

strongly recommended to better the overall

performance and reliability of the system.

Note 9

Motor cables and feedback cables exiting the cabinet going to the motor should be

separated as much as possible. Ideally, the use of separate conduits provides good isolation,

which can limit coupling of noise from motor to feedback cables.

Note 6

Feedback cable bonding is required for CE compliance. As with the motor cables, the

feedback cables should be bonded to the back panel. This bonding does two things. First, it

cuts down radiation from the drive, which may be in the form of high frequency energy

resulting from internal processor clocks. Second, it provides immunity for the drive. Since the

feedback device is located internal to the motor, it is going to pick up some noise currents and

transmit them along the feedback cable. The bonding directs the currents from the shield of

the feedback cable to back panel ground. This reduces the amount of noise entering the

drive.

Note 7

AC power lines that must be routed past other lines (such as motor cables or I/O lines) should

cross at a 90º angle. This minimizes the coupling effect. Additionally, the power lines should

be routed as close to the back panel as possible. Any noise currents on the lines are

capacitively coupled to the ground plane and not to other lines.

Note 8

Control (I/O) signals should be kept separate from all power and motor cables, if possible.

Keep control wiring as short as possible and use screened wire. Bonding is also

recommended but not required for CE compliance. A separation distance of 20 cm. (8 in.) is

sufficient in most cases. Where control cables must cross power cables, they should cross at

a 90º angle.

Loading...

Loading...