SEN01058-00 50 Disassembly and assembly

2 PC800, 850-8

Work equipment 1

Removal and installation of

bucket cylinder assembly 1

Back hoe

Removal

k Retract the arm and bucket cylinder piston

rods, lower the work equipment completely

to the ground, then set the lock lever to the

LOCK position.

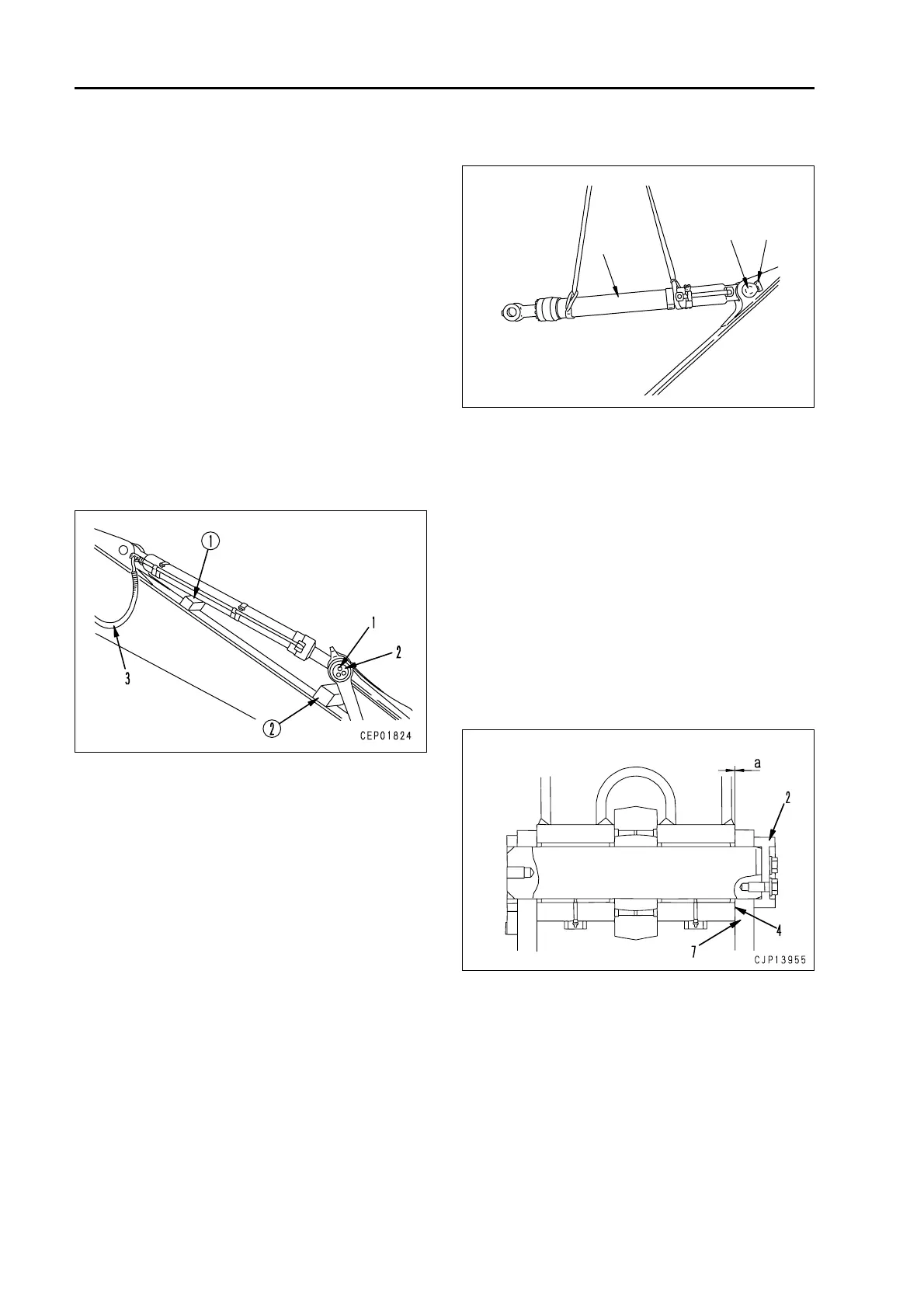

1. Set block [1] between bucket cylinder and arm,

and block [2] between link and arm.

2. Remove 3 pin lock bolts (1) and cover (2), then

using forcing screws, pull out. [*1]

a Check the number and thickness of the

shims, and keep in a safe place.

3. Start engine, and retract piston rod, then tie pis-

ton rod with wire to prevent it from coming out.

k Stop the engine and release the remain-

ing pressure in the circuit. For details, see

Testing and adjusting, “Releasing remain-

ing pressure from hydraulic circuit”.

4. Disconnect 2 hoses (3).

a Fit plugs in the hoses to prevent dust or

dirt from entering.

5. Sling bucket cylinder assembly (5), then

remove plate (6) and pull out pin (7). [*2]

a There are shims installed, so check the

number, thickness, and position, and keep

in a safe place.

6. Remove bucket cylinder assembly (5).

4 Bucket cylinder assembly:

520 kg (PC800, PC800LC)

940 kg (PC800SE, PC850SE)

560 kg (PC850)

Installation

q Carry out installation in the reverse order to

removal.

[*1]

2 Inside surface of bushing when assembling

pin: Anti-friction compound (LM-P)

2 Grease after assembling pin: Grease (LM-G)

k When aligning the position of the pin hole,

never insert your fingers in the hole.

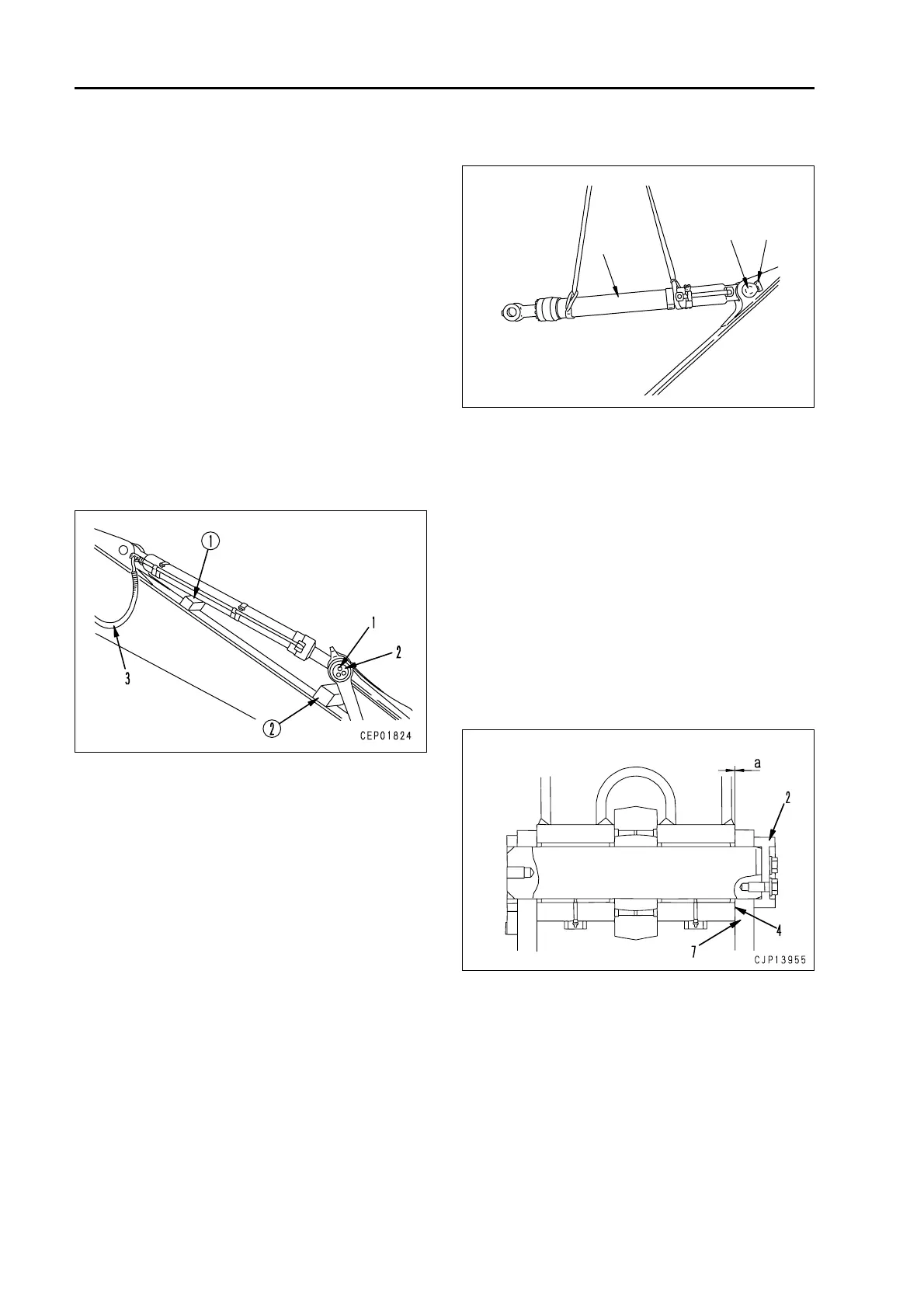

a Adjust with shims (4) so that the clearance (a)

between link (7) and cover (2) is less than 1

mm.

q Shim thickness: 0.8 mm(STD, LC)

1.0 mm(SE)

CEP00077

5

76

Loading...

Loading...