PC800, 850-8 25

30 Testing and adjusting SEN00912-02

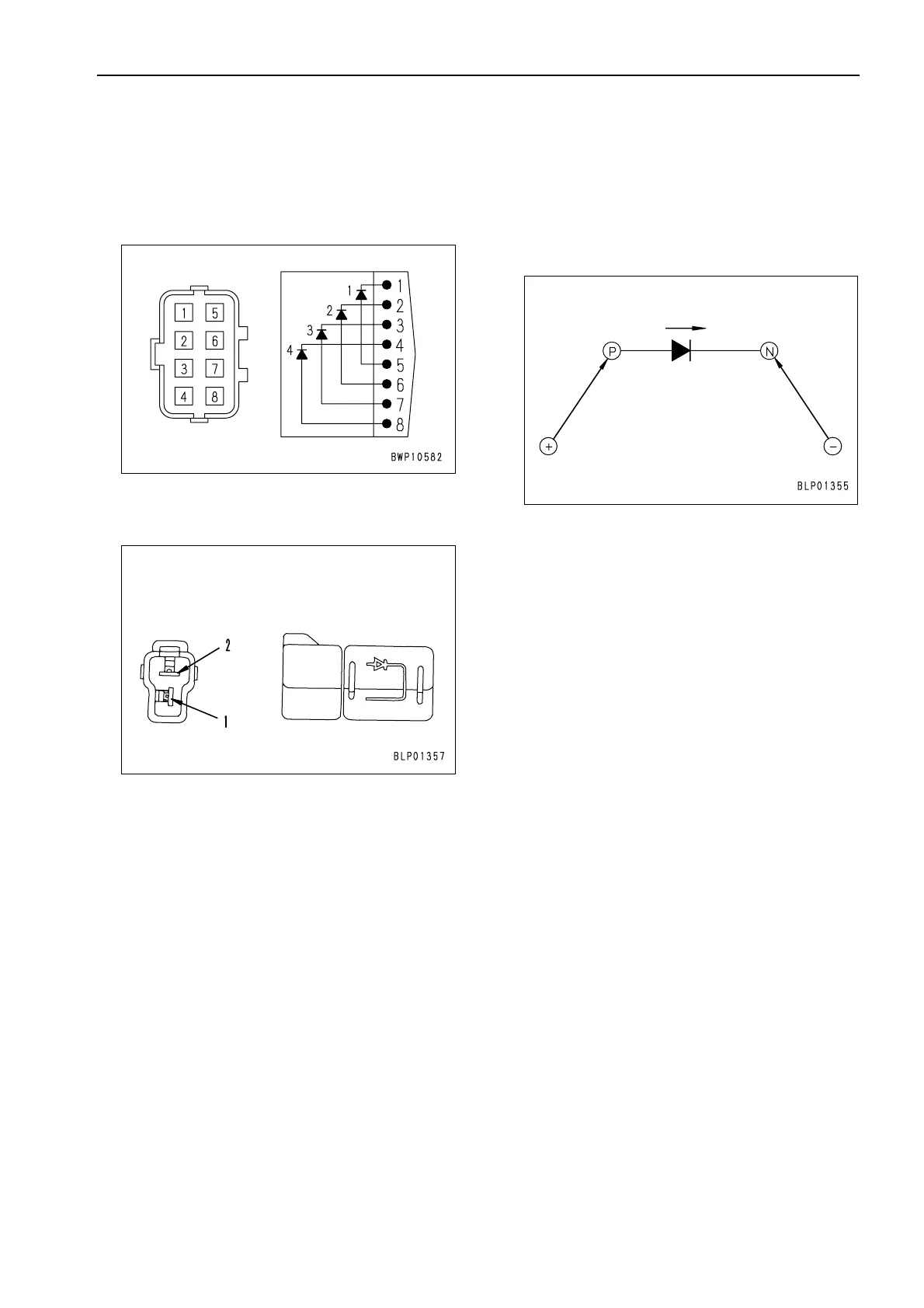

Inspection procedures for diode

a Check an assembled-type diode (8 pins) and

single diode (2 pins) in the following manner.

a The continuity direction of an assembled-type

diode is as shown in the diagram below.

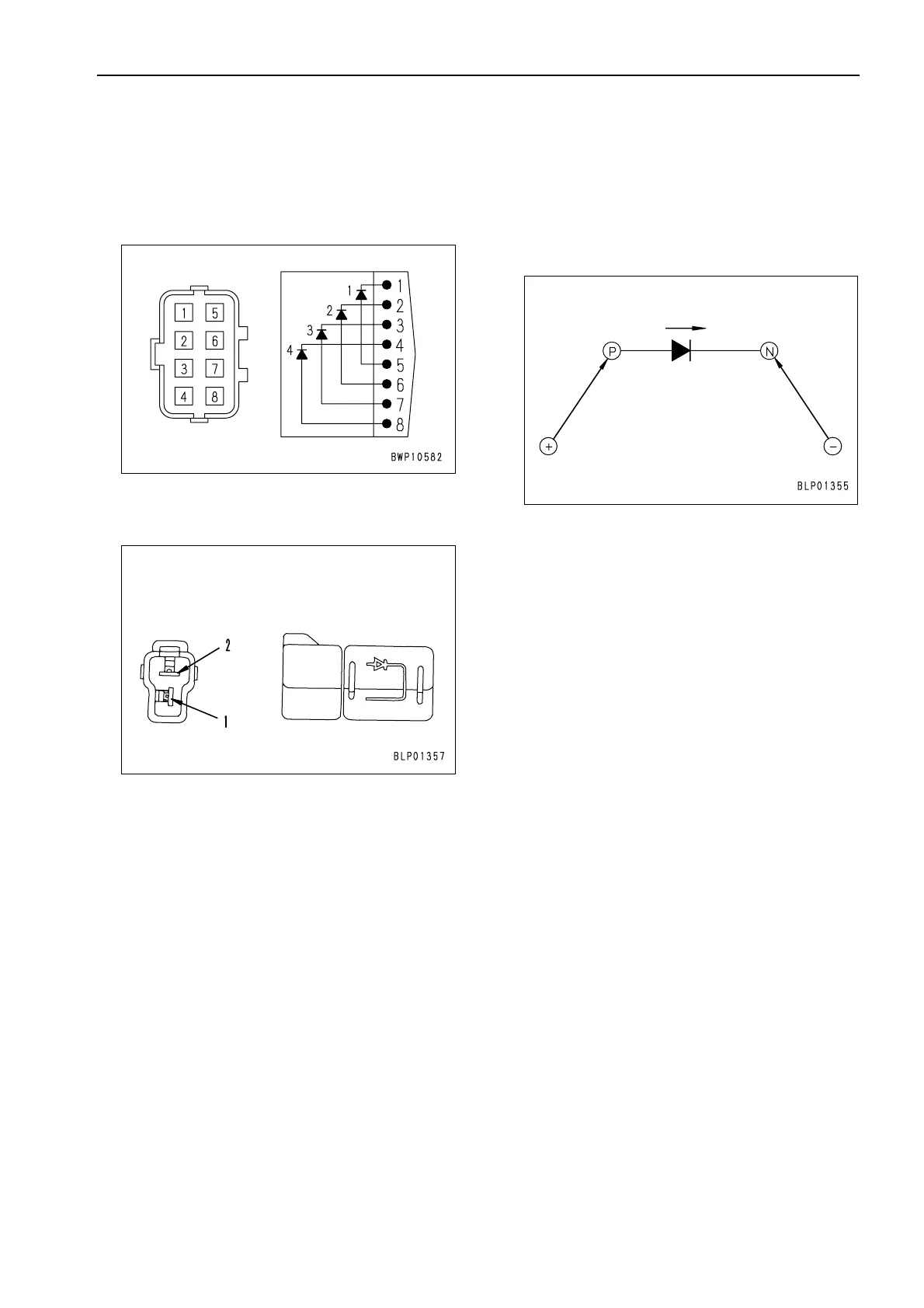

a The continuity direction of a single diode is

shown on the diode surface.

1. When using digital type circuit tester

1) Switch the testing mode to diode range and

confirm the indicated value.

a Voltage of the battery inside is displayed

with conventional circuit testers.

2) Put the red probe (+) of the test lead to the

anode (P) and the black probe (–) to the

cathode (N) of diode, and confirm the dis-

played value.

3) Determine if a specific diode is good or no

good with the indicated value.

• No change in the indicated value: No

continuity (defective).

• Change in the indicated value: Continui-

ty established (normal) (Note)

Note: A silicon diode shows a value between

400 and 600.

2. When using analog type circuit tester

1) Switch the testing mode to resistance range.

2) Check the needle swing in case of the fol-

lowing connections.

i) Put the red probe (+) of the test lead to

the anode (P) and the black probe (–) to

the cathode (N) of diode.

ii) Put the red probe (+) of the test lead to

the cathode (N) and the black probe (–)

to the anode (P) of diode.

3) Determine if a specific diode is good or no

good by the way the needle swings.

• If the needle does not swing in Case i),

but swings in Case ii): Normal (but the

breadth of swing (i.e. resistance value)

will differ depending on a circuit tester

type or a selected measurement range)

• If the needle swings in either case of i)

and ii): Defective (short-circuited inter-

nally)

• If the needle does not swing in any case

of i) and ii): Defective (short-circuited in-

ternally)

Loading...

Loading...