PC800, 850-8 21

30 Testing and adjusting SEN00786-02

Testing and adjusting

alternator belt tension

Testing procedure

1. Open the engine compartment cover on the

counterweight side.

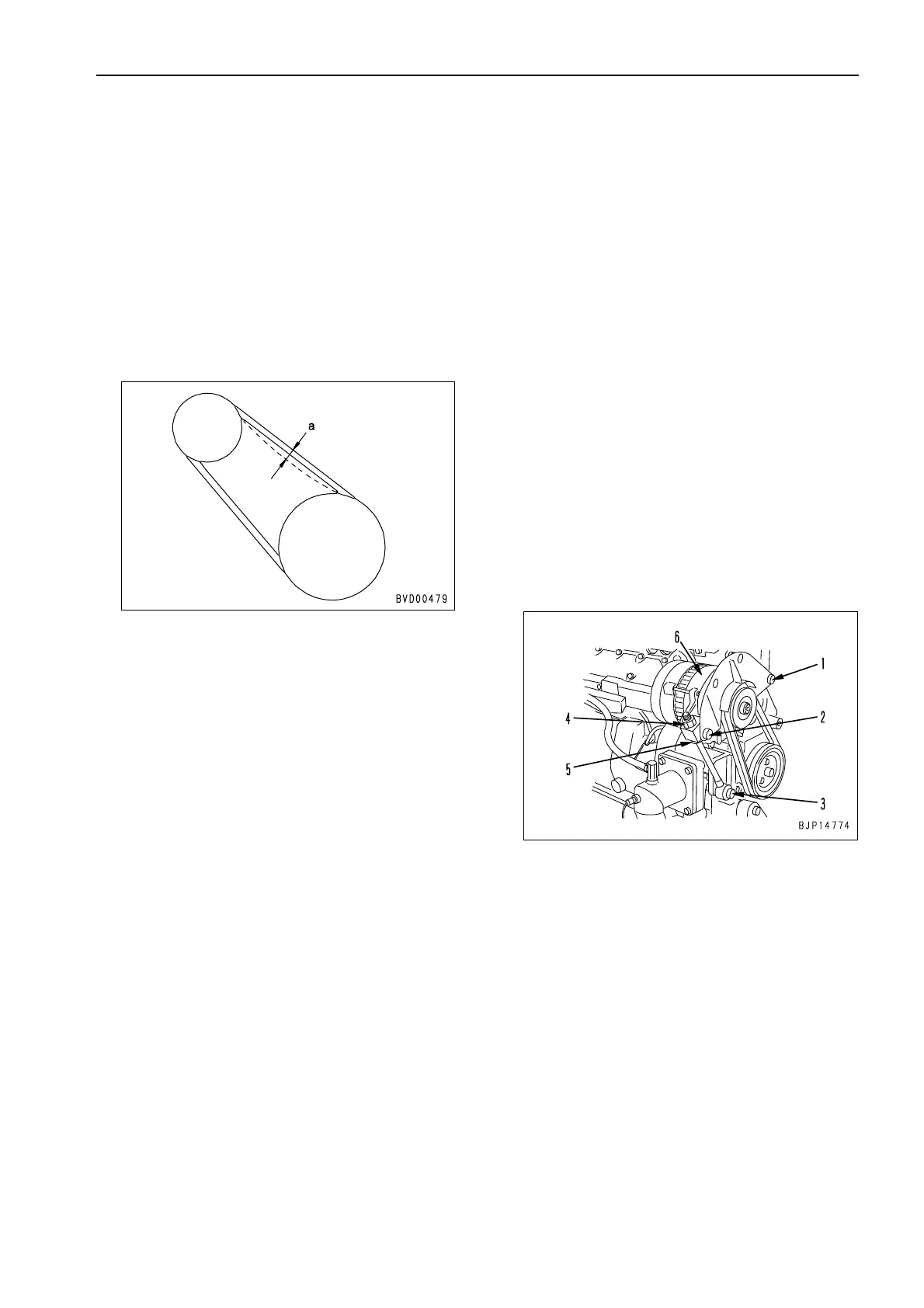

2. Measure the belt deflection (a) when pushing a

point midway between the alternator pulley and

the drive pulley with the finger.

a Deflection (a) when pressing force is approx.

58.8 N {approx. 6 kg}: 13 – 16 mm

Adjustment procedure

a Adjust the belt according to the following proce-

dure when the belt deflection is not normal.

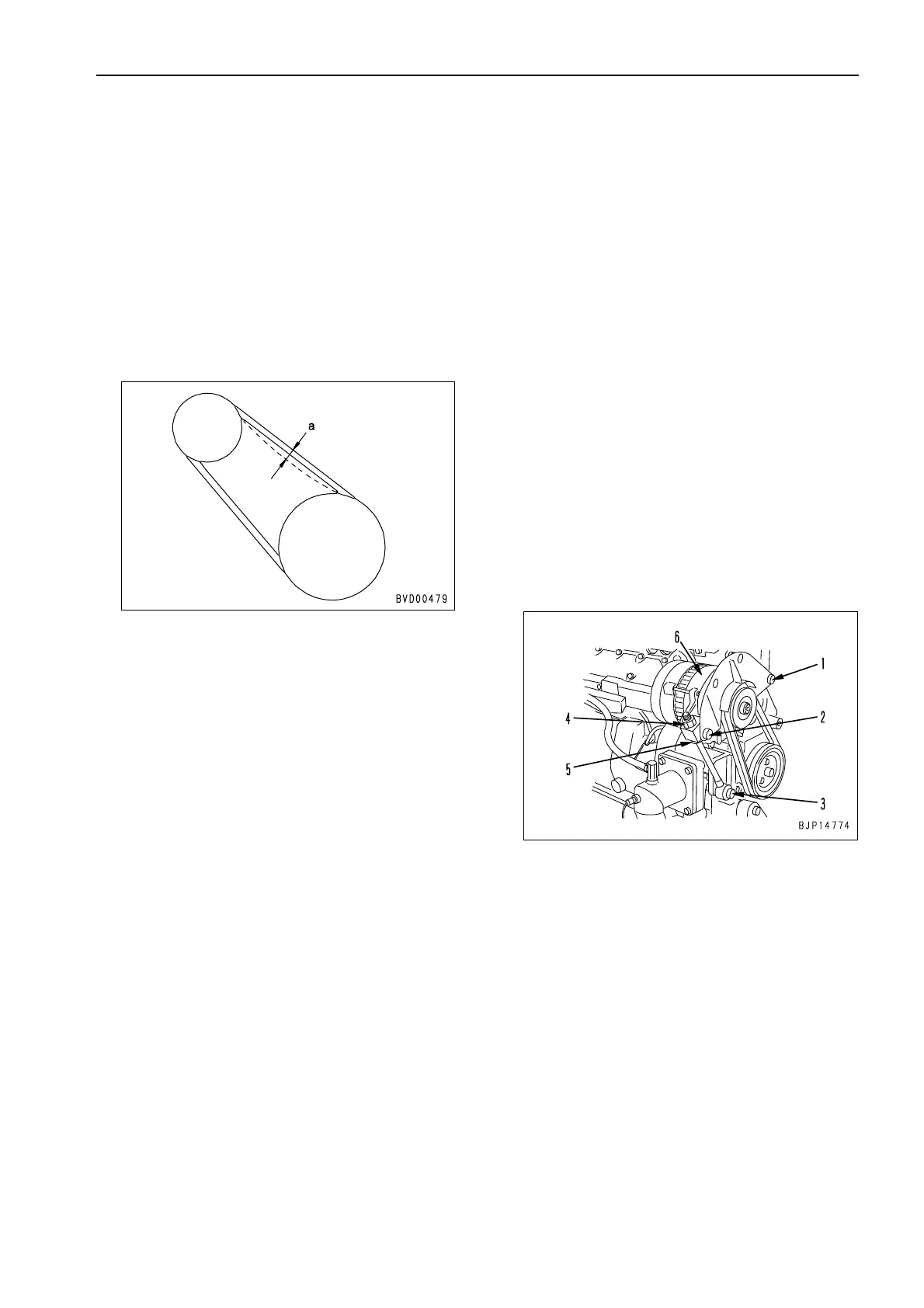

1. Loosen nuts and bolts (1), (2), (3) and (4) in this

order.

2. Turn nut (5) to move alternator (6), and adjust

the belt tension.

a Nut (5):

• It is moved to the side that belt is loos-

ened when turning it clockwise.

• It is moved to the side that belt is ten-

sioned when turning it counterclockwise.

a Test for breakage of each pulley, friction of

V-ditch, friction of belt, and contact between

belt and V-ditch.

a Replace it with new belt if it was too

stretched so that adjustability was lost, or cut

and crack occurred.

3. Tighten nuts and bolts (4), (3), (2) and (1) in this

order.

a When the V-belt was replaced, measure its

deflection again after one-hour operation

and then readjust it if necessary.

Loading...

Loading...