12 Servicing

12.2 Replacing seals and ball bearings

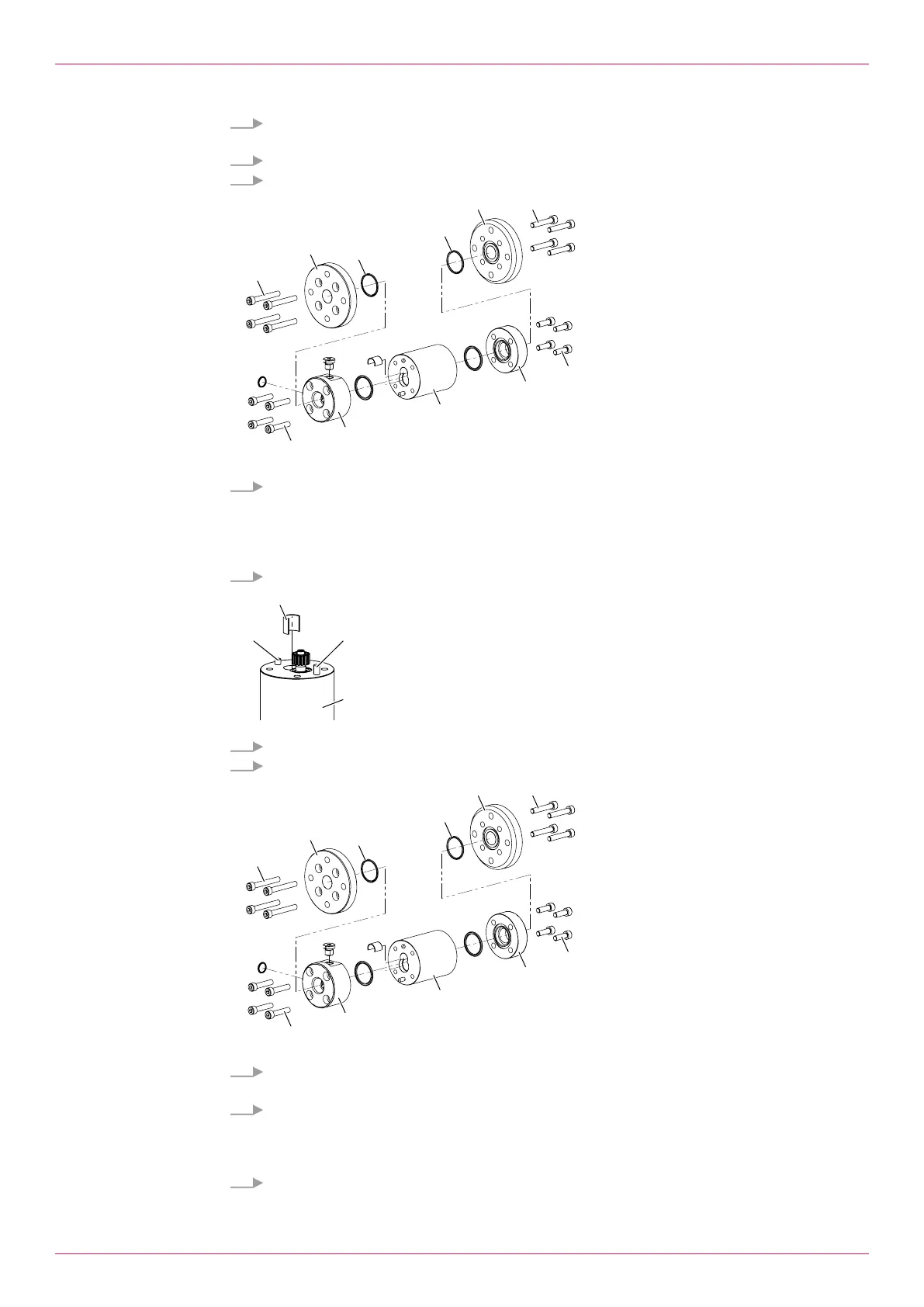

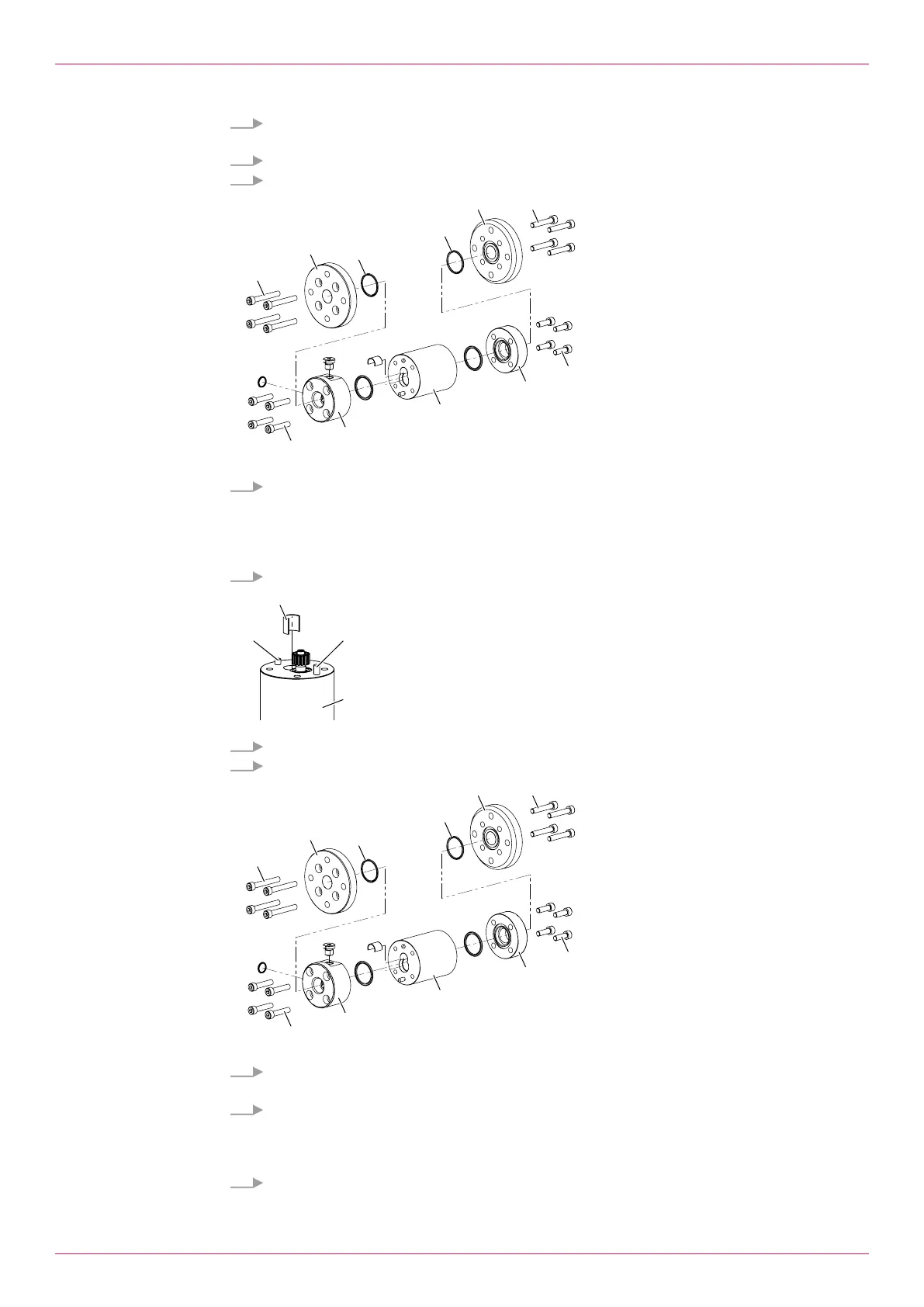

8. Pull the wedge lock washers25 and supporting ring24 onto the socket screw26. Ensure the cor-

rect positioning of the wedge lock washers (wedge on wedge).

9. Apply Loctite 242 to the socket screw26 and install on the measuring screw small22.

10. Install the circlips19 and20 on the floating bearing end.

11. At a pipe thread connection: Place the end cover4 on the measuring housing3, lay ready the

socket screws5.

-or-

At a flange connection: Place the end cover4 and flange cover31 with O-ring30 on the meas-

uring housing3, lay ready the socket screws32.

12. Pretension the oiled screws crosswise and tighten with torque.

13. Carefully slide the screw set into the measuring housing3.

14. Slide the distance sleeve9 into the hole of the measuring screw small22.

15. Place the end cover2 onto the measuring housing. Please ensure that the tapered dowel pinsA

in the measuring housing match the fitting holes.

16. At a BSPP connection: Lay ready the socket screws1.

- or -

At a flange connection: Place on the flange cover28 with O-ring29 and lay ready the socket

screws27.

17. Pretension the oiled screws crosswise and tighten with torque.

Operating instructions

OIO 14en-GB Edition 2020-01

35

Loading...

Loading...