12 Servicing

12.2 Replacing seals and ball bearings

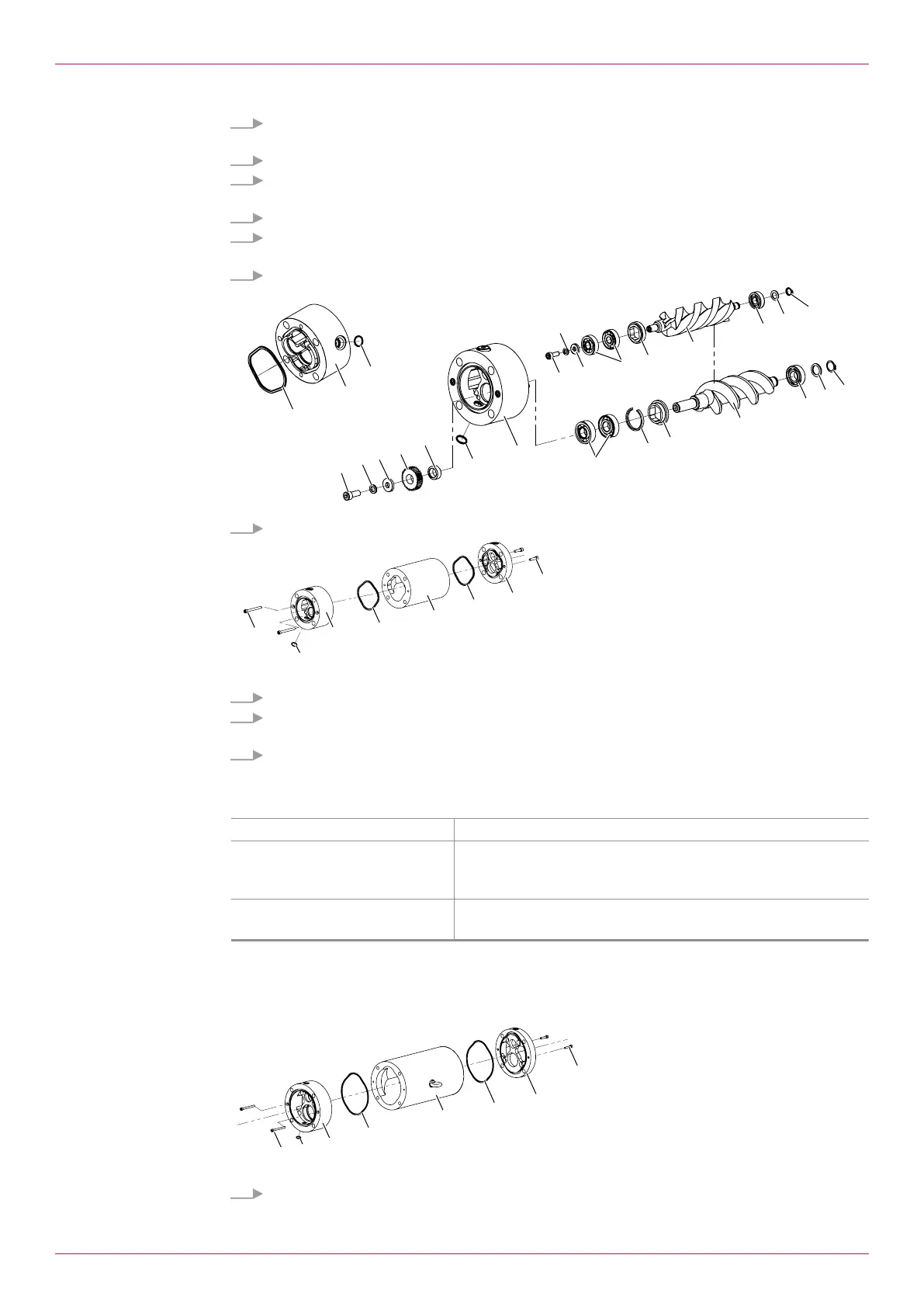

7. Press the measuring screws into the ball bearings in the bearing cover3. Support the respective

inner ring of the ball bearing.

8. Slide the distance ring8 on the measuring screw large17 and press on the pole wheel7.

9. Pull the wedge lock washers10 and supporting ring9 onto the socket screw11. Observe the lay-

out of the wedge lock washer (wedge on wedge).

10. Apply Loctite 242 to the socket screw11 and install on the measuring screw small24.

11. Pull the wedge lock washers5 and supporting ring6 onto the socket screw4. Observe the layout

of the wedge lock washer (wedge on wedge).

12. Apply Loctite 242 to the socket screw4 and install on the measuring screw large17.

15

16

13

17

18

19

20

4

5

6

7

8

14

21

22

23

24

12

25

26

28

27

3

3

14

2

13. Install the support rings19 and22 as well as the circlips20 and21 on the floating bearing end.

14. Insert the O-ring32 into the bearing cover29.

15. Place the bearing cover29 onto the measuring housing1 and tighten the socket screws30 with

torque.

16. Carefully insert the bearing cover3 with premounted measuring unit into measuring housing1

and tighten the socket screws31 with torque.

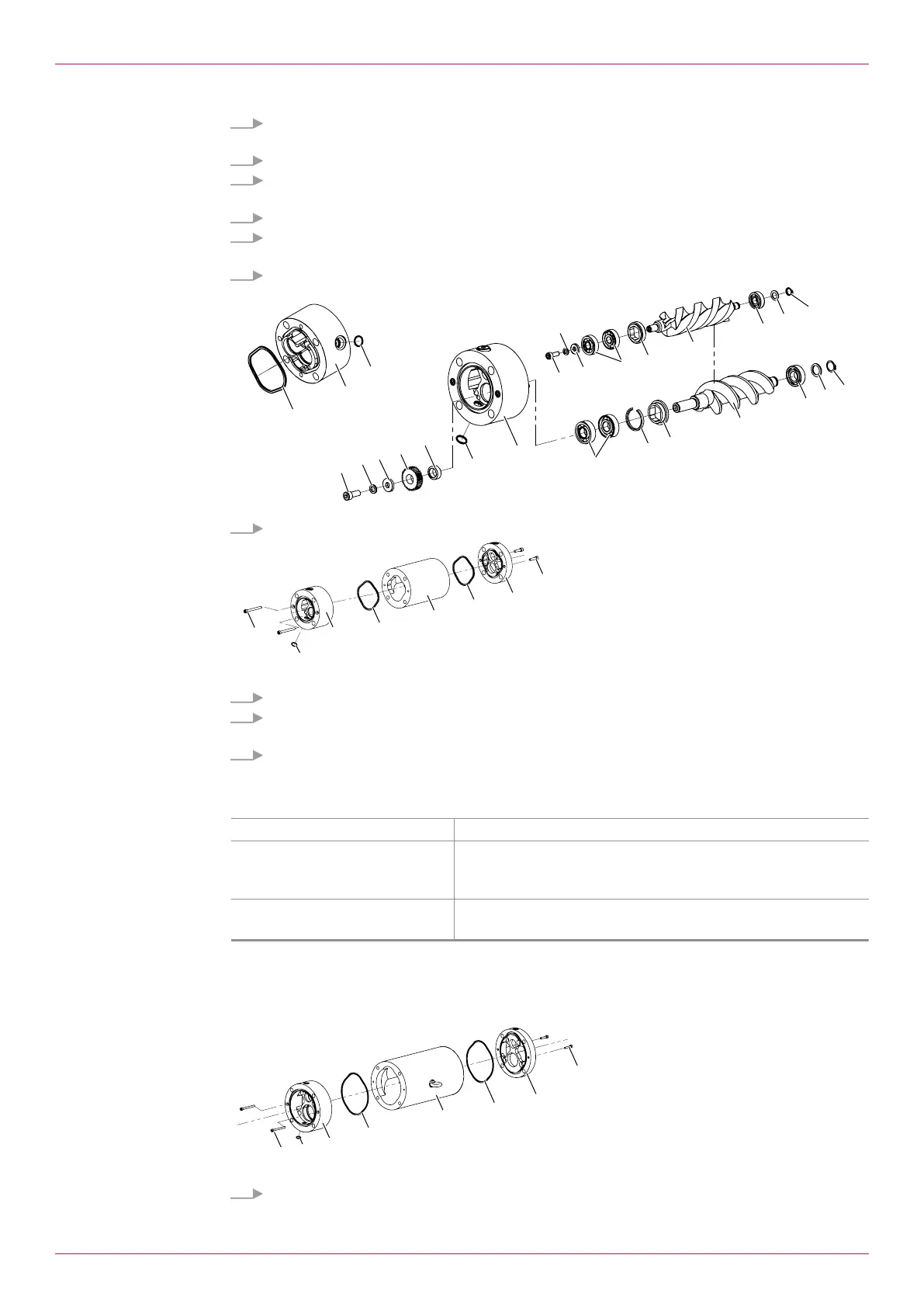

12.2.7 Removing seals and ball bearings OMG-100/OMG-140

Personnel qualification: o Fitter

Personal protective equipment: o Work clothing

o Protective gloves

o Safety boots

Aids: o Plastic hammer

o Extractor

Requirement:

ü Flowmeter removed from system

ü Completion consisting of socket screws, flanges and seals removed

ü Pick up inserts removed

1. Remove the socket screws27 and30, take off the bearing cover29 and remove the O-ring28.

38

OIO 14en-GB Edition 2020-01

Operating instructions

Loading...

Loading...