6 Commissioning/Start-up/Shutdown

28 of 76

CTN / CTN-H

CAUTION

Insufficient quantity of lubricating oil in the reservoir of the constant level oiler

Damage to the bearings!

▷ Regularly check the oil level.

▷ Always fill the oil reservoir completely.

▷ Keep the oil reservoir properly filled at all times.

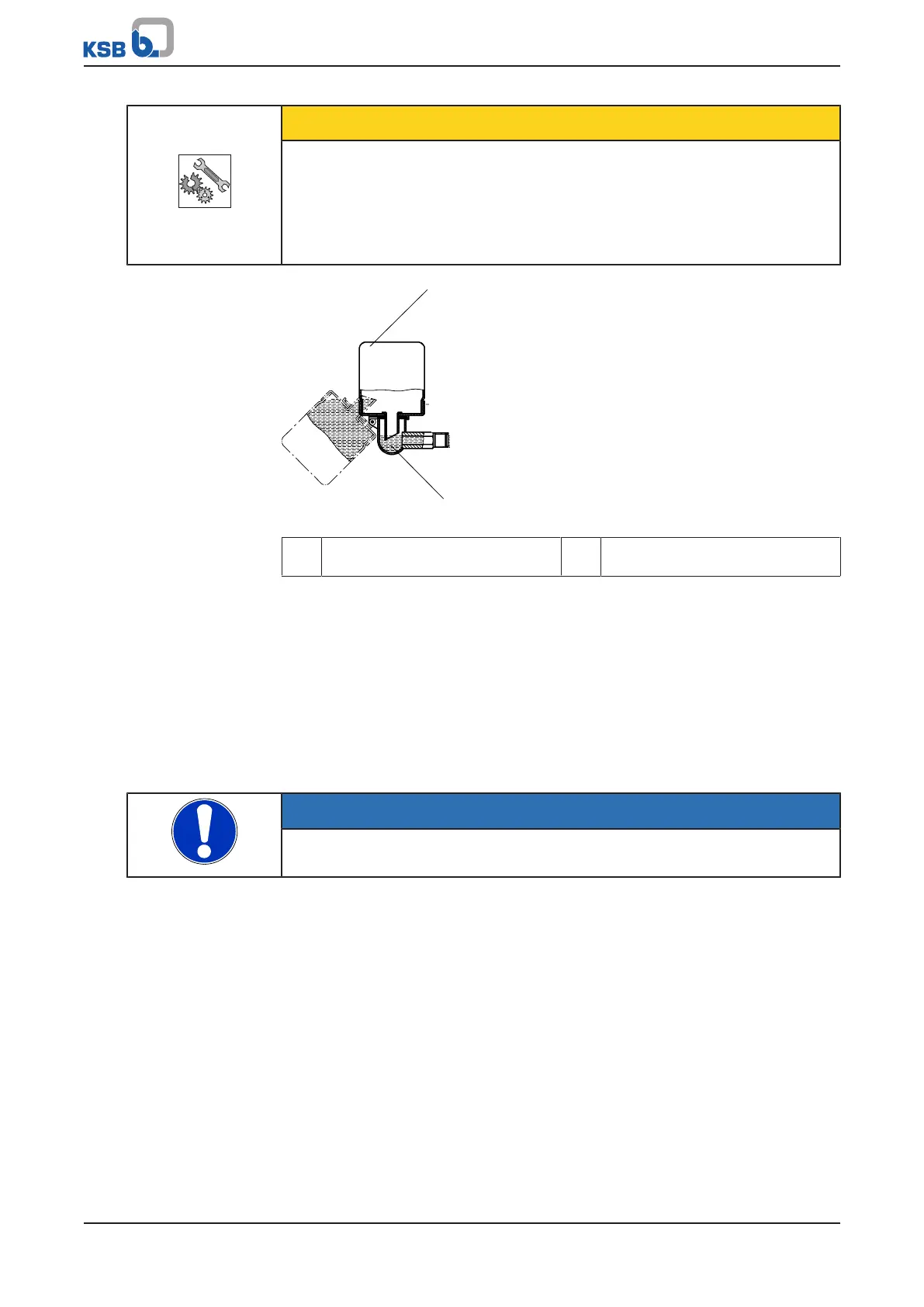

Fig.6: Constant level oiler

1 Constant level oiler 2 Connection elbow of the constant

level oiler

1. Hinge down the reservoir of the constant level oiler (1).

2. Fill oil through the open connection elbow.

3. Completely fill the reservoir of the constant level oiler (1).

4. Snap the constant level oiler (1) back into its operating position.

5. After approximately 5 minutes, check the oil level in the glass reservoir of the

constant level oiler (1).

The oil reservoir must be properly filled at all times to provide a constant oil

level. Repeat steps 1 - 4, if necessary.

6. To check the function of the constant level oiler (1), slowly drain oil via the

screw plug until air bubbles develop in the reservoir.

NOTE

An excessively high oil level can lead to a temperature rise and to leakage of the

fluid handled or oil.

6.1.3 Shaft seal

Shaft seals are fitted prior to delivery.

Observe the instructions on dismantling (ðSection7.4.5,Page45) or assembly

(ðSection7.5.5,Page52) .

Quench reservoir If applicable, fill the quench reservoir in accordance with the general arrangement

drawing.

Double mechanical seal Prior to starting up the pump, apply barrier pressure as specified in the general

arrangement drawing.

External liquid feed Apply the quantities and pressures specified in the data sheet and the general

arrangement drawing.

Loading...

Loading...