7 Servicing/Maintenance

57 of 76

CTN / CTN-H

3. Turn bearing nut 923 to the right.

Move the rotor to the upper stop.

4. Measure the dimension of the upper edge of the bearing nut/shaft end.

5. Lower the rotor from the upper stop by 0.5x the overall clearance.

One full turn of the bearing nut will cause the rotor to move upwards or

downwards by 1.5mm.

6. Screw the centring sleeve to the bearing nut with hexagon socket head cap

screws 914.12 and secure against rotation.

The throughholes in the bearing nut align with the tapped holes in the centring

sleeve.

7.5.7 Preloading the mechanical seal

Move the setting ring 500.12 and shaft protecting sleeve in the direction of the

motor to the setting dimension of 5mm (distance to the seal cover) and secure on

shaft 210 with grub screw 904.32.

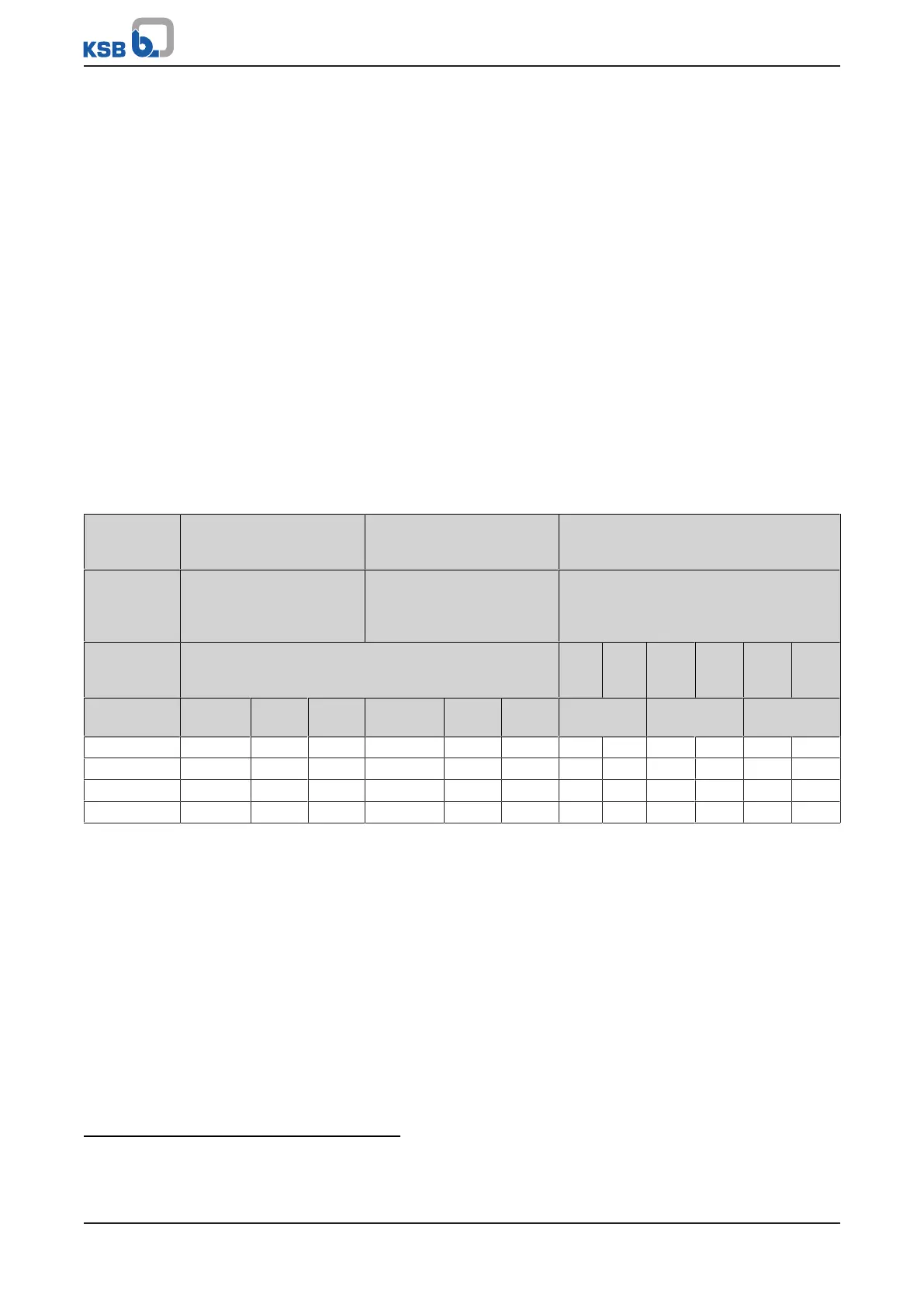

7.6 Tightening torques

Use a torque wrench to tighten the bolted connections (902.01/920.01) between the

volute casing and the bearing bracket lantern.

Table27: Tightening torques [Nm] for screwed connections

Material of

stud/hexagon

nut

C35E+Qt/C 35 A4-70/A4-70 1.7709+QT/1.7258+QT

Stamp mark

on

stud/hexagon

nut

12)

YK/Y A4-70/A4-70 GA/G

Bearing

bracket

lantern

13)

A B A B A B

New

threads

14)

-15 %

15)

-20 %

15)

New

threads

14)

-15 %

15)

-20 %

15)

New

threads

14)

-15 %

15)

-20 %

15)

M10 - - - 30 25,5 24 47 30 39,9 25,5 37,6 24

M12 40 34 32 55 46,7 44 80 55 68 46,7 64 44

M16 100 85 80 155 131,7 124 190 155 161,5 131,7 152 124

M20 - - - 200 170 160 330 200 280,5 170 264 160

7.7 Spare parts stock

7.7.1 Ordering spare parts

Always quote the following data when ordering replacement or spare parts:

▪ Order number

▪ Order item number

▪ Consecutive number

▪ Type series

▪ Size

▪ Material variant

▪ Seal code

▪ Year of construction

12) Treat unstamped screwed connections like material pair C35/E+QT/C 35.

13) A: made of ductile material – except for JL1040; B: made of material JL1040

14) These values are determined on the basis of a friction coefficient of μ=0.12.

15) After repeated tightening of the threads and in case of good lubrication the values shall be reduced by 15 to 20%.

Loading...

Loading...