PumpDrive

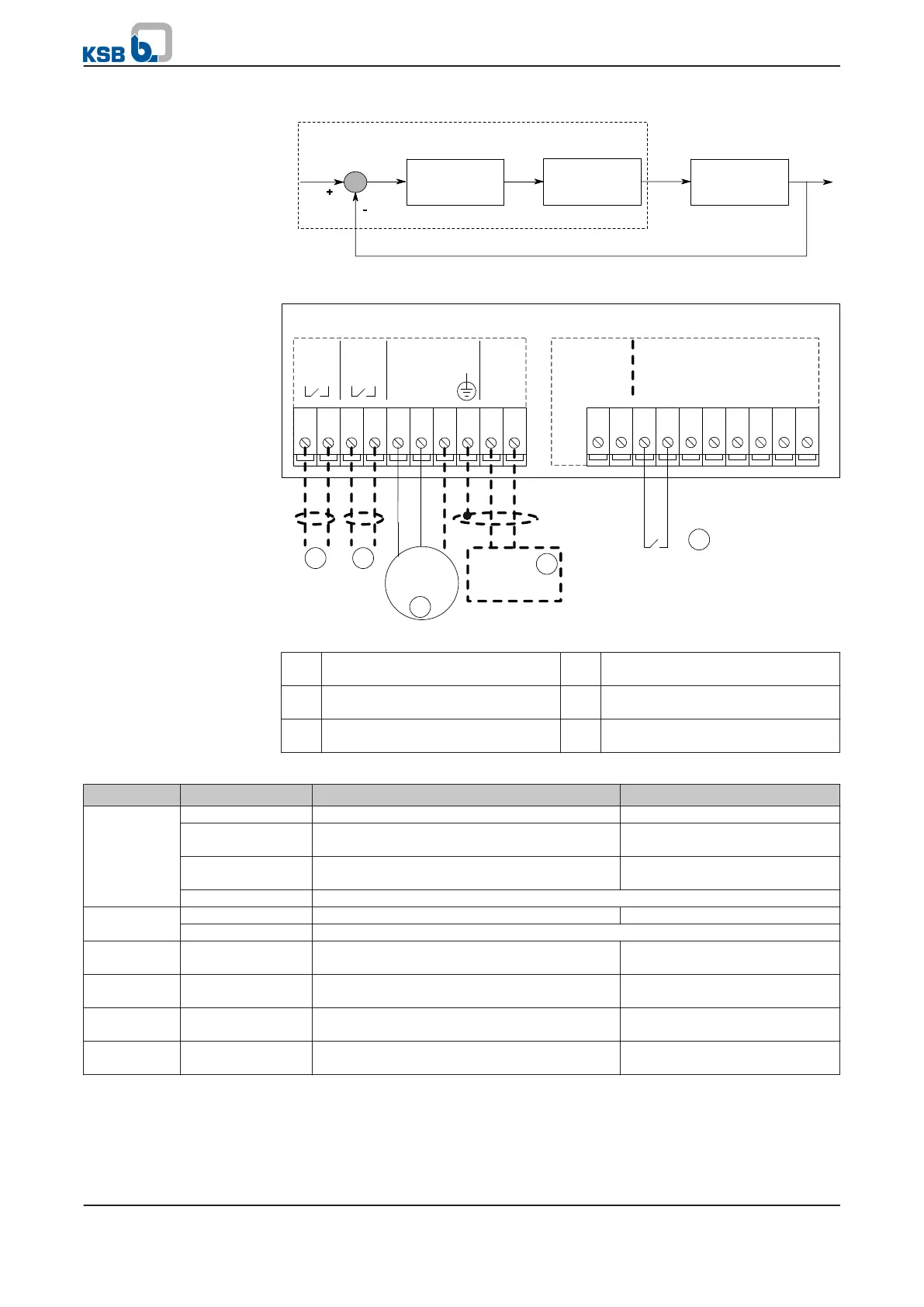

∆ ∆p ∆n ∆

∆

U[V,f]

p setpoint

Controlled system

p

Speed controller

actual

p

Process controller

(PI controller)

actual

(PI controller)

Fig. 28: Closed-loop control mode block diagram

G

ND

DI6

DI5

D

I4

D

I3

DI2

D

I1

+

24V

A

GN

D

AN

-

O

U

T

20191817161514131211

1

AGND

AIN1

GND

AIN2

+24V

NO2

COM2

NO1

COM1

10931 2 4 5 6 7 8

Sensor

4...20mA

P4

P7

5

2

0V

S ignal

3 4

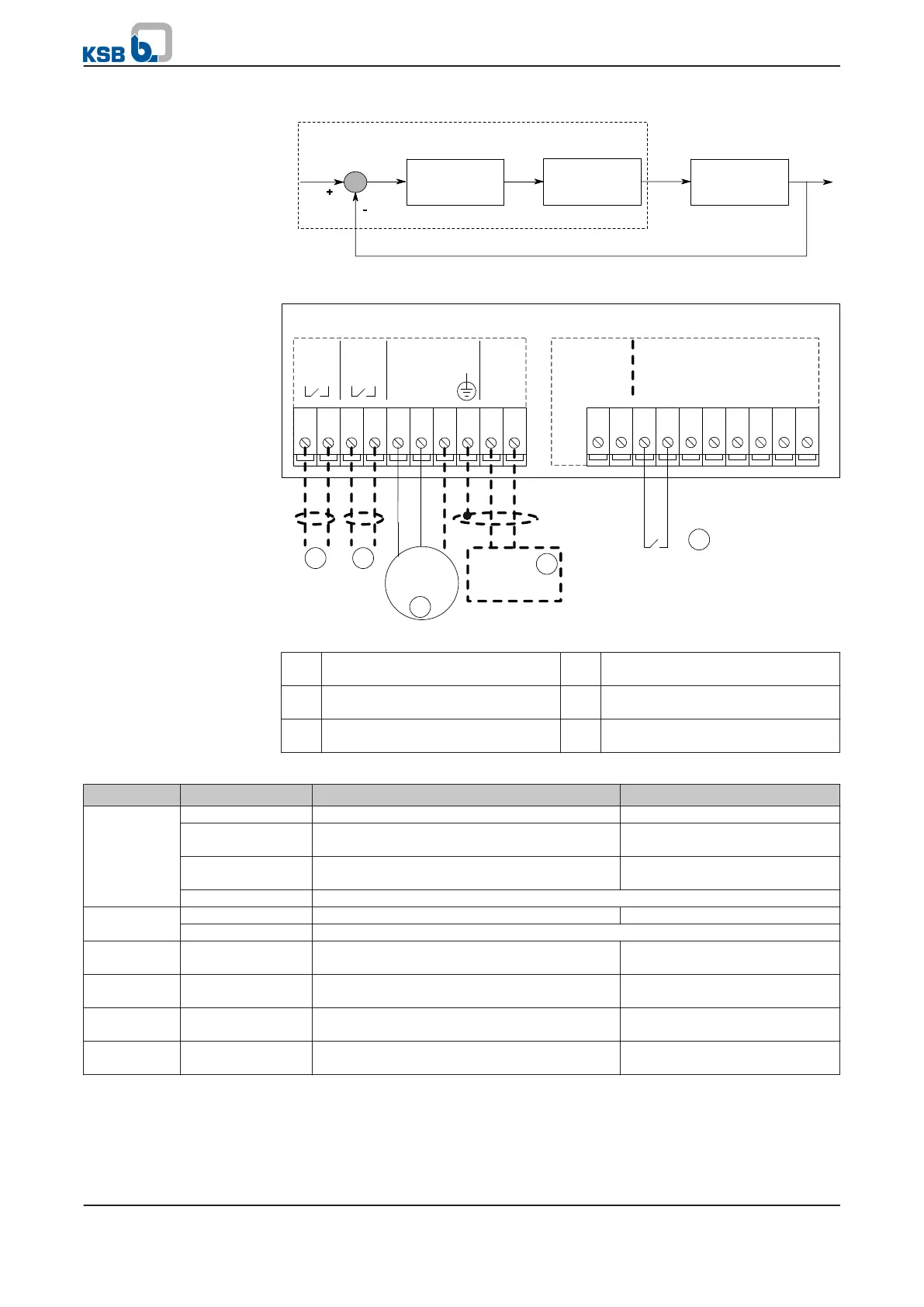

Fig. 29: Terminal wiring diagram, closed-loop control mode (dashed line = optional)

1 Start/stop 2 External setpoint signal

(⇨ Section 7.1.1.2 Page 49)

3 Signal relay 1

(⇨ Section 7.4.2 Page 95)

4 Signal relay 2

(⇨ Section 7.4.2 Page 95)

5 External sensor signal

(⇨ Section 7.1.1.4 Page 54)

Table 54: Closed-loop control mode

Function Input/connection Specification Setting range/parameter value

Setpoint

specification

P7 terminal strip Analog input 1 (P7: 9/10) 5-10 V DC ≙ 25-50 Hz

Graphical control

panel

Configurable setpoint

(3-5-2-1)

50 - 100 % ≙ 25 - 50 Hz

Standard control

panel

(⇨ Section 6.1.5 Page 39) 50 - 100 % ≙ 25 - 50 Hz

Field bus See field bus module literature

Start

command

P4 terminal strip Digital input 1 (P4: 13/14) Start in automatic mode

Field bus See field bus module literature

Process

controller

Graphical control

panel

PI Auto (3-9-1-6) Deactivated

Process

controller

Graphical control

panel

PI mode (3-9-1-1) Disabled

Operating

mode

Graphical control

panel

MAN-OFF-AUTO AUTO

Process

controller

Graphical control

panel

PI mode (3-9-1-1) Enabled

Circuit diagram (⇨ Section 9 Page 99)

7 Commissioning/shutdown

PumpDrive

55 of 162

Loading...

Loading...