The controller's integral term (integration over time) ensures steady-state accuracy in

controlled systems with compensation function. Once the controlled variable has

reached its steady-state value, the offset will be zero, provided parameterisation is

correct. Depending on its value, the integral term of the controller PI Integral Tm

(3-9-1-3)

has the following effect on the control characteristics:

▪ Low value selected for PI Integral Tm

(3-9-1-3)

: Faster elimination of offset, if any.

This may, however, cause the value of the controlled variable to oscillate around

the setpoint and result in control process instability.

▪ Large value selected for PI Integral Tm

(3-9-1-3)

: Considerably reduces the

controller's response speed

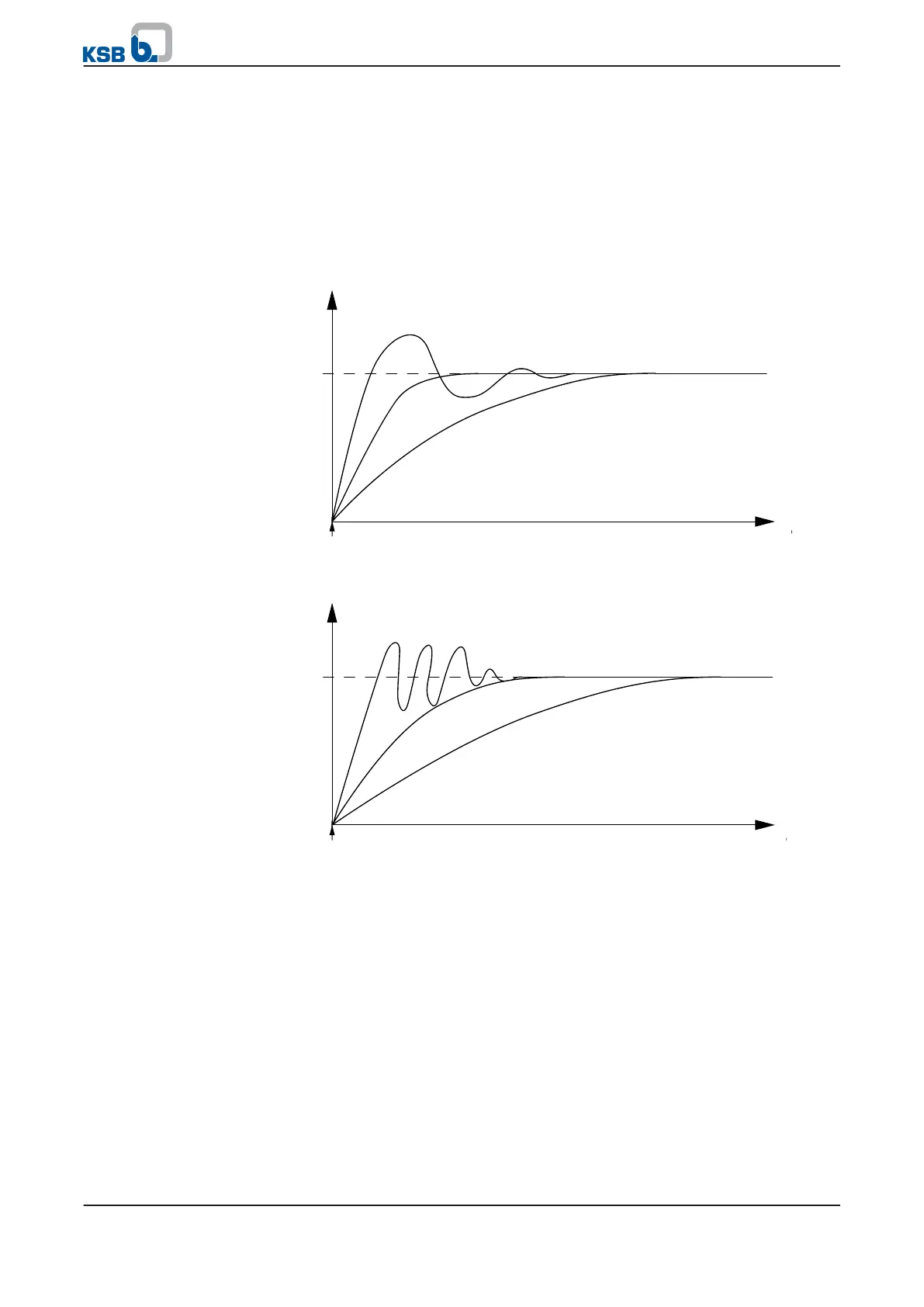

Actual value

Setpoint

3--9--1--2

Value too large

3--9--1--2

Value optimal

3--9--1--2

Value too small

Time

Point in time at which a sudden

change in setpoint occurs (dashed line)

Fig. 35: Setting the proportional gain

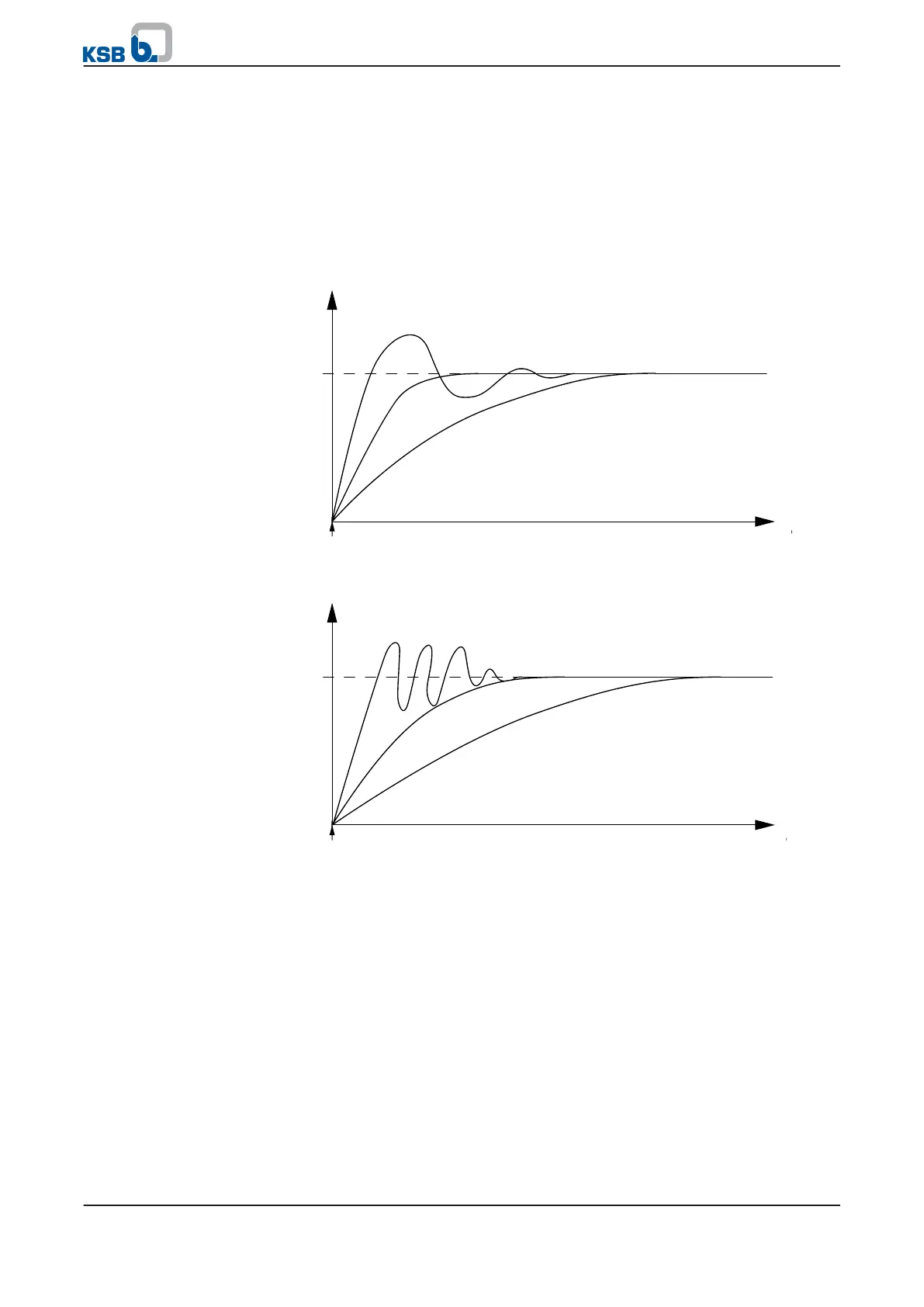

Actual value

Setpoint

3--9--1--3

Value too large

3--9--1--3

Value optimal

3--9--1--3

Value too small

Time

Point in time at which a sudden

change in setpoint occurs (dashed line)

Fig. 36: Setting the integral term

7.1.1.4.1 Closed-loop control mode via control panel

The setpoint can be specified using the control panel. For this purpose, the Setpoint

Source 2 parameter

(3-5-4-2)

must be set to Configurable Setpoint (factory setting).

The setpoint unit is set using the Setpoint Unit parameter

(3-2-2-1)

. Depending on

the unit selected, the setpoint is specified using the Configurable Setpoint parameter

(3-5-2-1)

. The Max Setpoint parameter

(3-5-1-3)

(⇨ Section 7.1.1.2 Page 49) must be

set identically to parameter

(3-8-2-8)

Analog IN 1 High or

(3-8-3-8)

Analog IN 2 High,

depending on the feedback source selected.

PumpDrive is to control the system to achieve a setpoint of 6.7 bar in a differential

pressure control process. For this purpose, a differential pressure sensor (4 - 20 mA)

with a measuring range of 0 to 10 bar is connected to analog input 2 of PumpDrive.

The setpoint is specified using the control panel.

Example

7 Commissioning/shutdown

PumpDrive

59 of 162

Loading...

Loading...