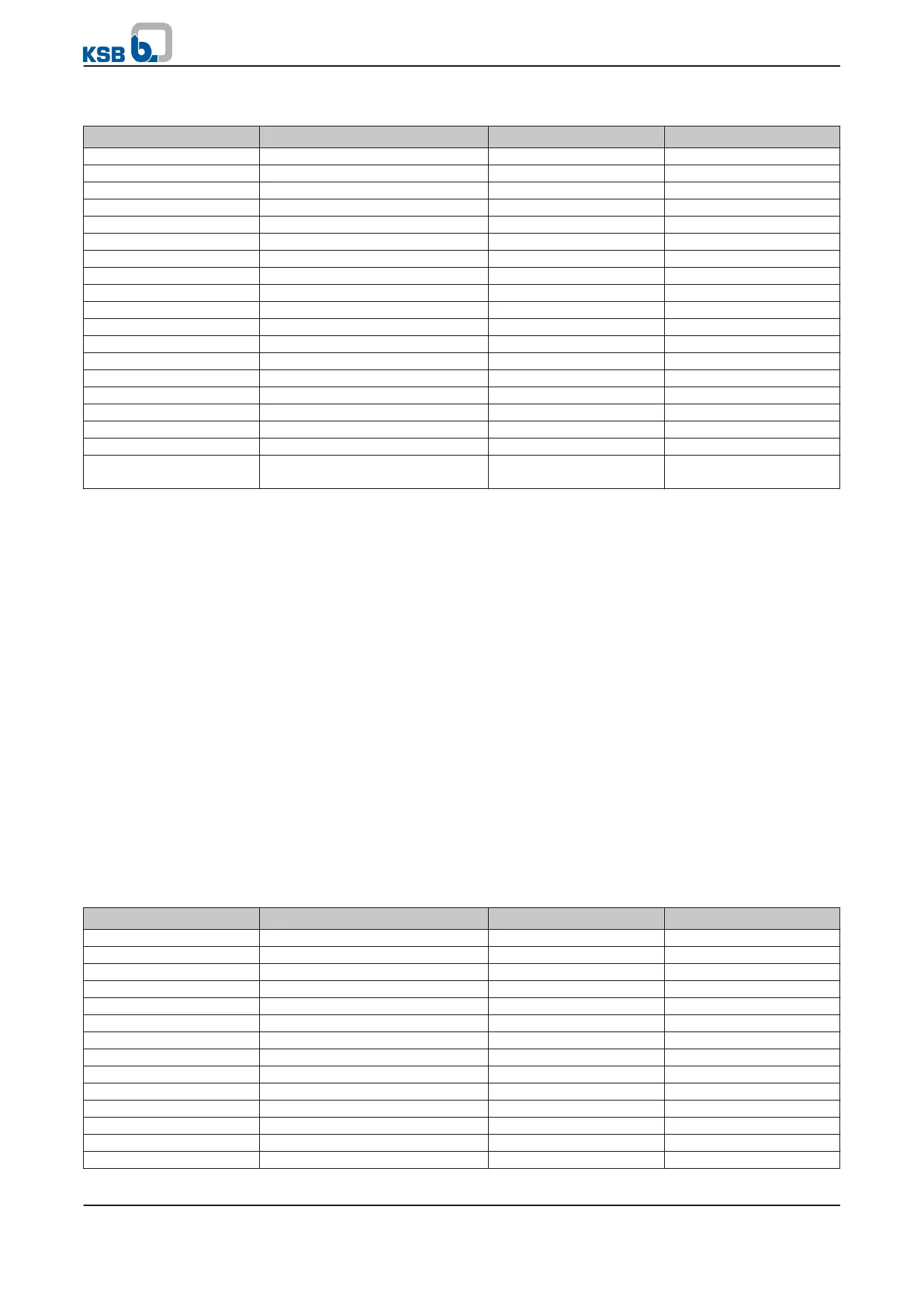

Table 56: Sample parameters for closed-loop control mode using the control panel

Parameter Description Settings Factory setting

3-2-2-1

Physical unit of setpoint bar %

3-2-2-3

Physical unit of pressure bar %

3-5-1-2

Minimum setpoint 0 bar 0 %

3-5-1-3

Maximum setpoint 10 bar 100 %

3-5-4-1

Setpoint source 1 None Analog IN 1

3-5-4-2

Setpoint source 2 Configurable Setpoint Configurable Setpoint

3-5-4-3

Setpoint source 3 None Remote Setpoint

3-5-2-1

Configurable Setpoint 6,7 bar 0 %

3-8-3-1

Configuration of analog input 2 Current Current

3-8-3-2

Analog IN 2 Low current 4 mA 4 mA

3-8-3-3

Analog IN 2 High current 20 mA 20 mA

3-8-3-4

Unit of Analog IN 2 bar %

3-8-3-5

Low value for Analog IN 2 0 bar 0 %

3-8-3-6

High value for Analog IN 2 10 bar 100 %

3-9-1-6

PI Auto mode Disabled Enabled

3-9-1-1

Disable/enable PI controller Enabled Disabled

3-9-1-4

Control direction of PI controller Negative Negative

3-9-1-5

Process type of PI controller Constant pressure Constant pressure

3-9-2-1

Selection of feedback (actual

value) source

Analog IN 2 Analog IN 2

Maintain the following sequence for activating the process controller:

1.

Change parameter

3-9-1-6

.

2. Change parameter

3-9-1-1

.

The value displayed for parameter 1-3-1-3 Setpoint is 6.7 bar.

Parameter 1-3-1-1 for the actual feedback value in the corresponding unit displays

the current actual value.

7.1.1.4.2 Closed-loop control mode with external setpoint signal

By default, analog input 1 (terminal P7:9 AIN1 and 10 AGND P7) is set as the setpoint

source (

3-5-4-1

). A direct voltage of 0 to 10 V (0 to 100 %) is expected as the signal. If

a current signal, e.g. 4 - 20 mA (0 - 100 %) is to be used, the Al 1 Setting parameter

(3-8-2-1)

has to be changed accordingly. Parameters Analog IN 1 Low Voltage

(3-8-2-2)

to Analog IN 1 High Current

(3-8-2-5)

can be used to match the setpoint

input to the signal received.

PumpDrive is to control the system to achieve a setpoint of 6.7 bar in a differential

pressure control process. For this purpose, a differential pressure sensor (4 - 20 mA)

with a measuring range of 0 to 10 bar is connected to analog input 2 of PumpDrive.

The setpoint is specified using an external setpoint signal (4 - 20 mA) via analog

input 1. For the desired setpoint of 6.7 bar, 10.72 mA must be applied at analog

input 1.

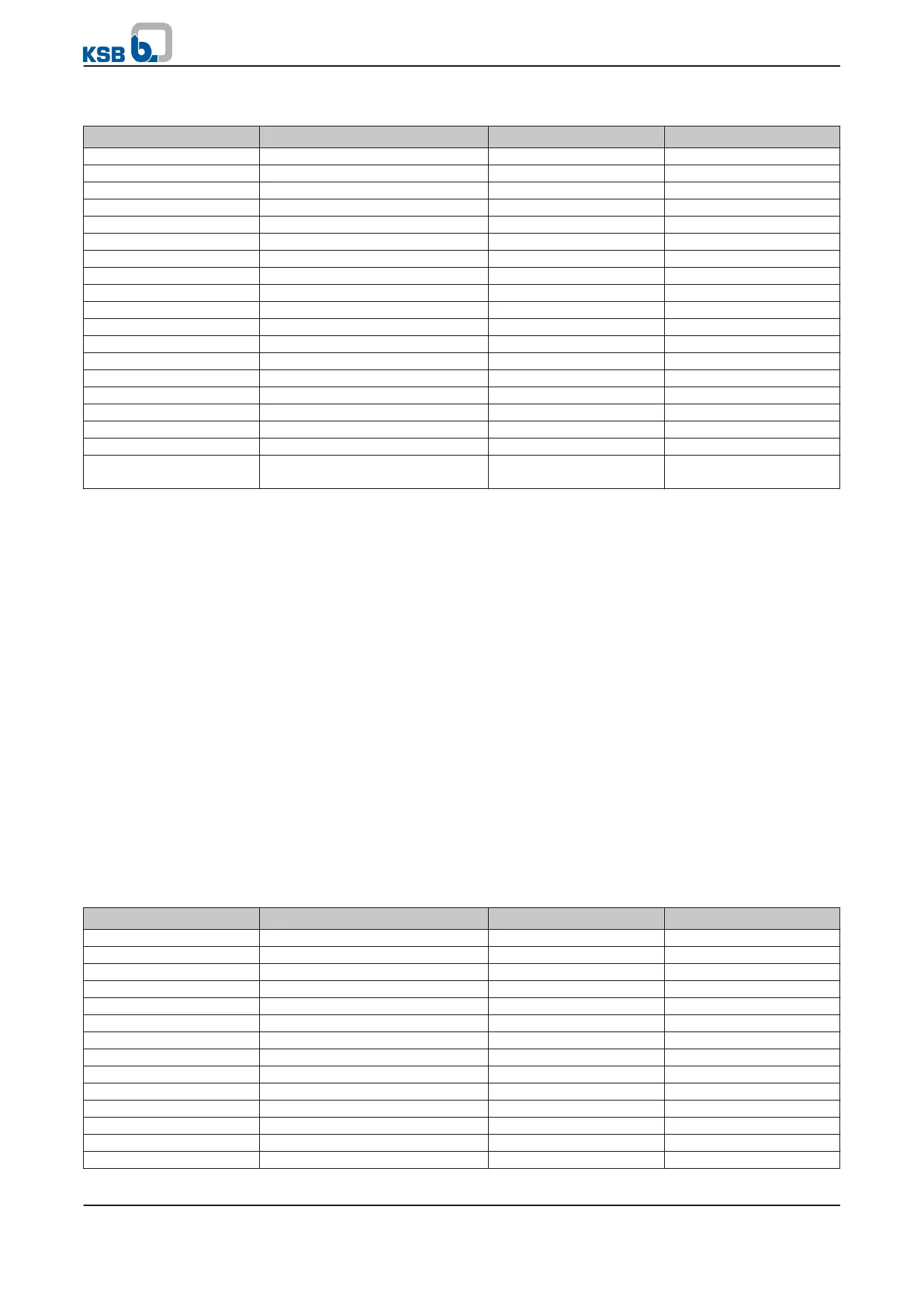

Table 57: Parameters for closed-loop control mode using an external setpoint signal

Parameter Description Possible settings Factory setting

3-2-2-1

Physical unit of setpoint bar %

3-2-2-3

Physical unit of pressure bar %

3-5-1-2

Minimum setpoint 0 bar 0 %

3-5-1-3

Maximum setpoint 10 bar 100 %

3-5-4-1

Setpoint source 1 Analog IN 1 Analog IN 1

3-5-4-2

Setpoint source 2 None Configurable Setpoint

3-5-4-3

Setpoint source 3 None Remote Setpoint

3-8-2-1

Configuration of analog input 1 Current Current

3-8-2-2

Analog IN 1 Low current 4 mA 4 mA

3-8-2-3

Analog IN 1 High current 20 mA 20 mA

3-8-2-4

Unit of Analog IN 1 bar %

3-8-2-5

Low value for Analog IN 1 0 bar 0 %

3-8-2-6

High value for Analog IN 1 10 bar 100 %

3-8-3-1

Configuration of analog input 2 Current Current

Example

7 Commissioning/shutdown

60 of 162

PumpDrive

Loading...

Loading...