S-73

07-E3B SERIES, WSM

ENGINE

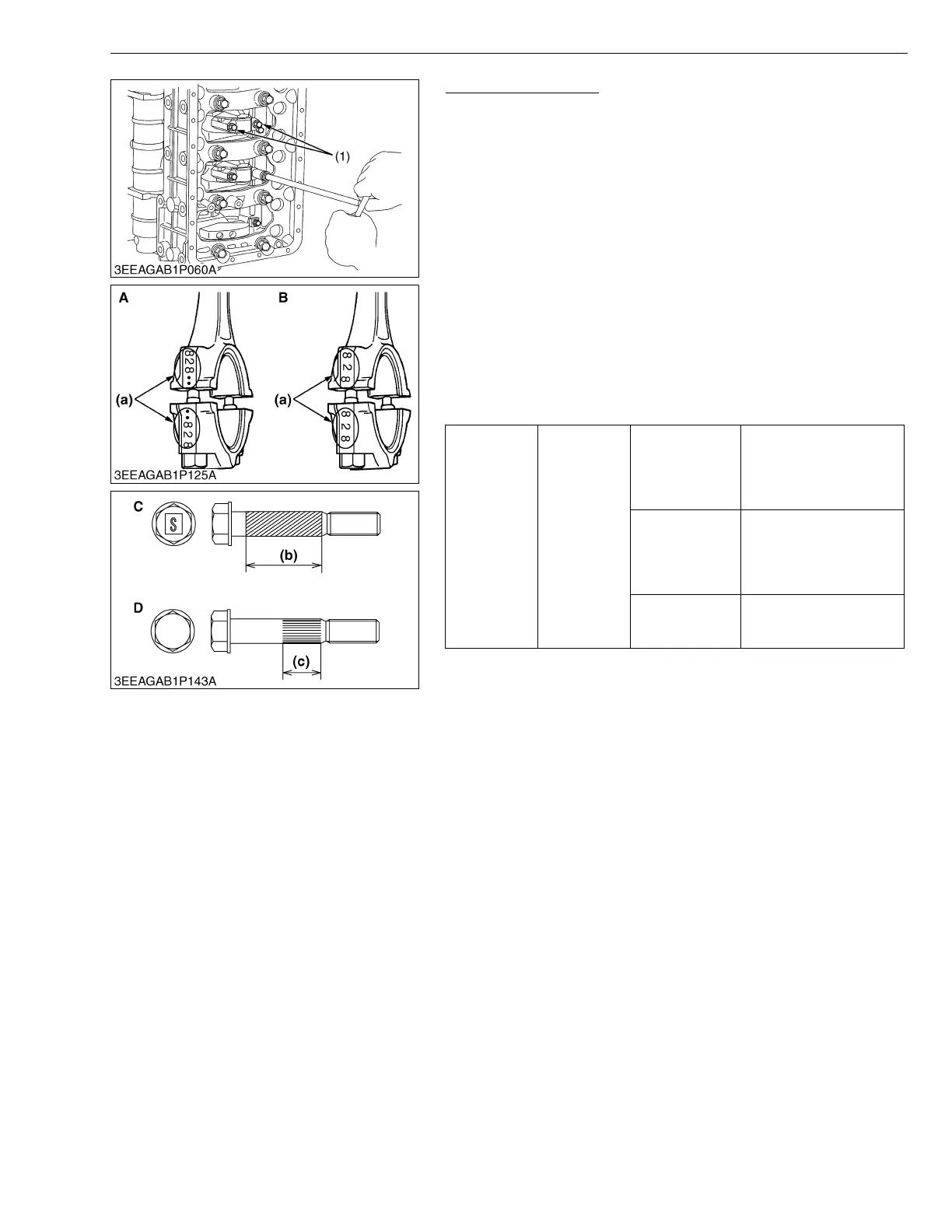

Connecting Rod Cap

1. Remove the connecting rod screws (1) from connecting rod cap.

2. Remove the connecting rod caps.

(When reassembling)

• Align the marks (a) with each other. (Face the marks toward the

injection pump.)

• Apply engine oil to the connecting rod screws (1) and lightly

screw it in by hand, then tighten it to the specified torque.

If the connecting rod screw (1) won’t be screwed in smoothly,

clean the threads.

If the connecting rod screw (1) is still hard to screw in, replace it.

• When using the existing crank pin metal again, put tally marks on

the crank pin metal and the connecting rod in order to keep their

positioning.

• At the time of reassembling the connecting rod caps, use a

combination of the connecting rod screws with the same

specified tightening torque.

W1058252

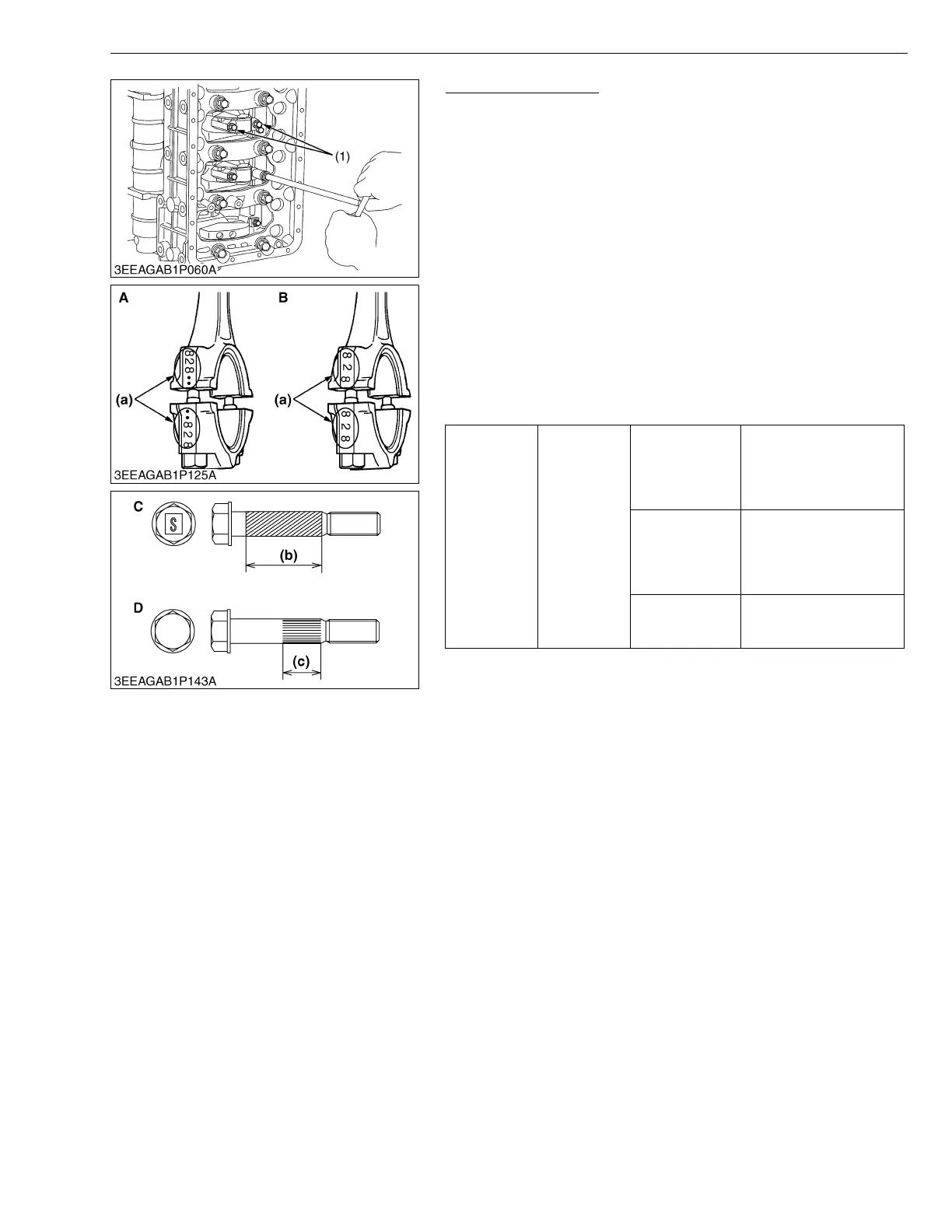

Tightening

torque

Connecting

rod screw

V2607-DI-T-E3B

[Serial No. :

8G0001

to 9K9999]

(Fig. C)

45 to 49 N·m

4.5 to 5.0 kgf·m

33 to 36 lbf·ft

V2607-DI-E3B

V2607-DI-T-E3B

[Serial No. :

9L0001 and

above] (Fig. D)

41 to 45 N·m

4.1 to 4.6 kgf·m

30 to 33 lbf·ft

V3007-DI-T-E3B

V3307-DI-T-E3B

69 to 73 N·m

7.0 to 7.5 kgf·m

51 to 54 lbf·ft

(1) Connecting Rod Screw

(a) Mark

(b) Serration (Spiral) : 26 mm (1.0 in.)

(c) Serration (Axial direction) :

13 mm (0.51 in.)

A : V2607-DI-E3B / V2607-DI-T-E3B

B : V3007-DI-T-E3B / V3307-DI-T-E3B

C : Old Connecting Rod Screw

D : New Connecting Rod Screw

Loading...

Loading...