This page contains Kval, Inc. proprietary information and is not to be duplicated or disclosed to unauthorized persons.

51

GENERAL AIR CIRCUITRY TROUBLE SHOOTING

IF A CYLINDER IS NOT FUNCTIONING CORRECTLY HERE ARE A COUPLE OF

ITEMS TO CHECK:

1. Check the air pressure to the machine.

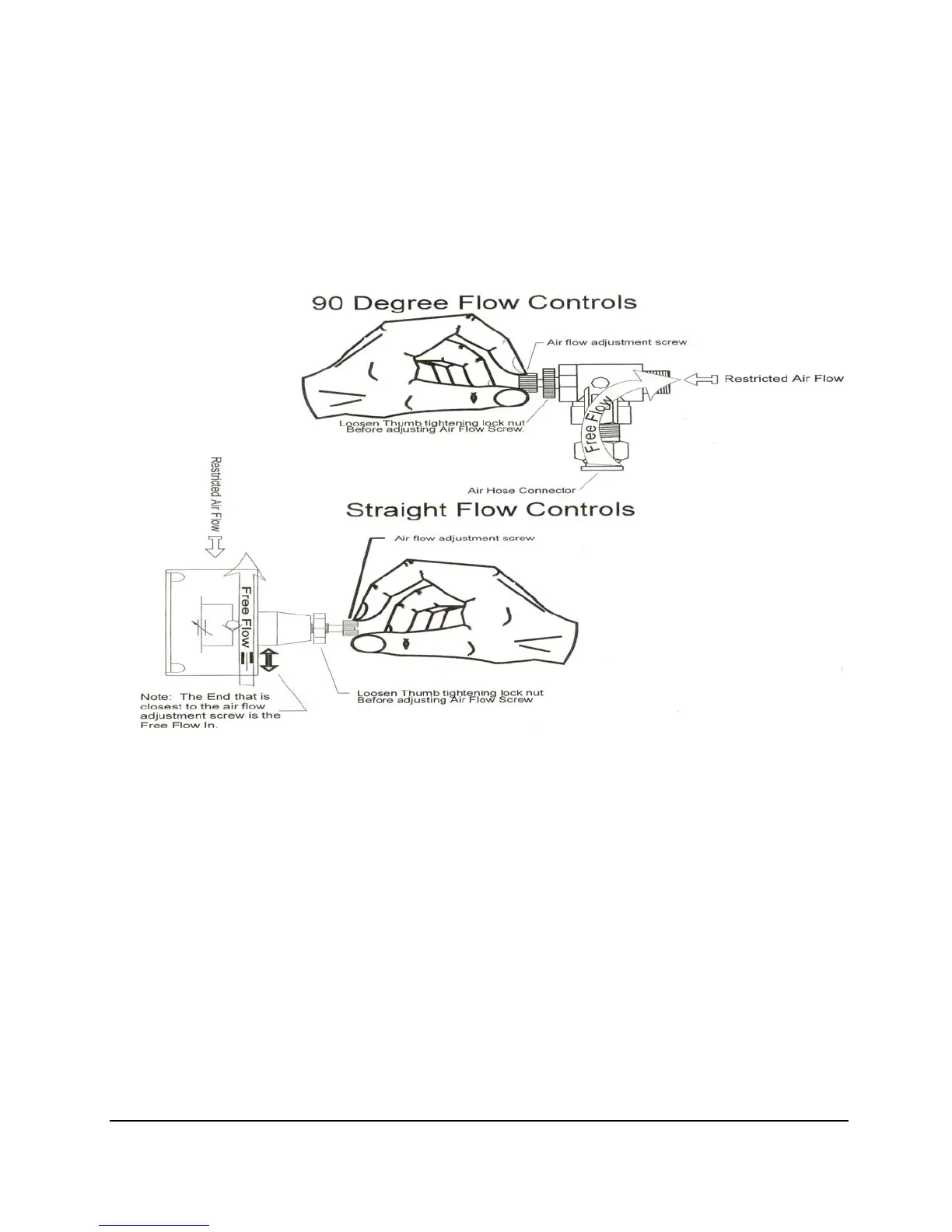

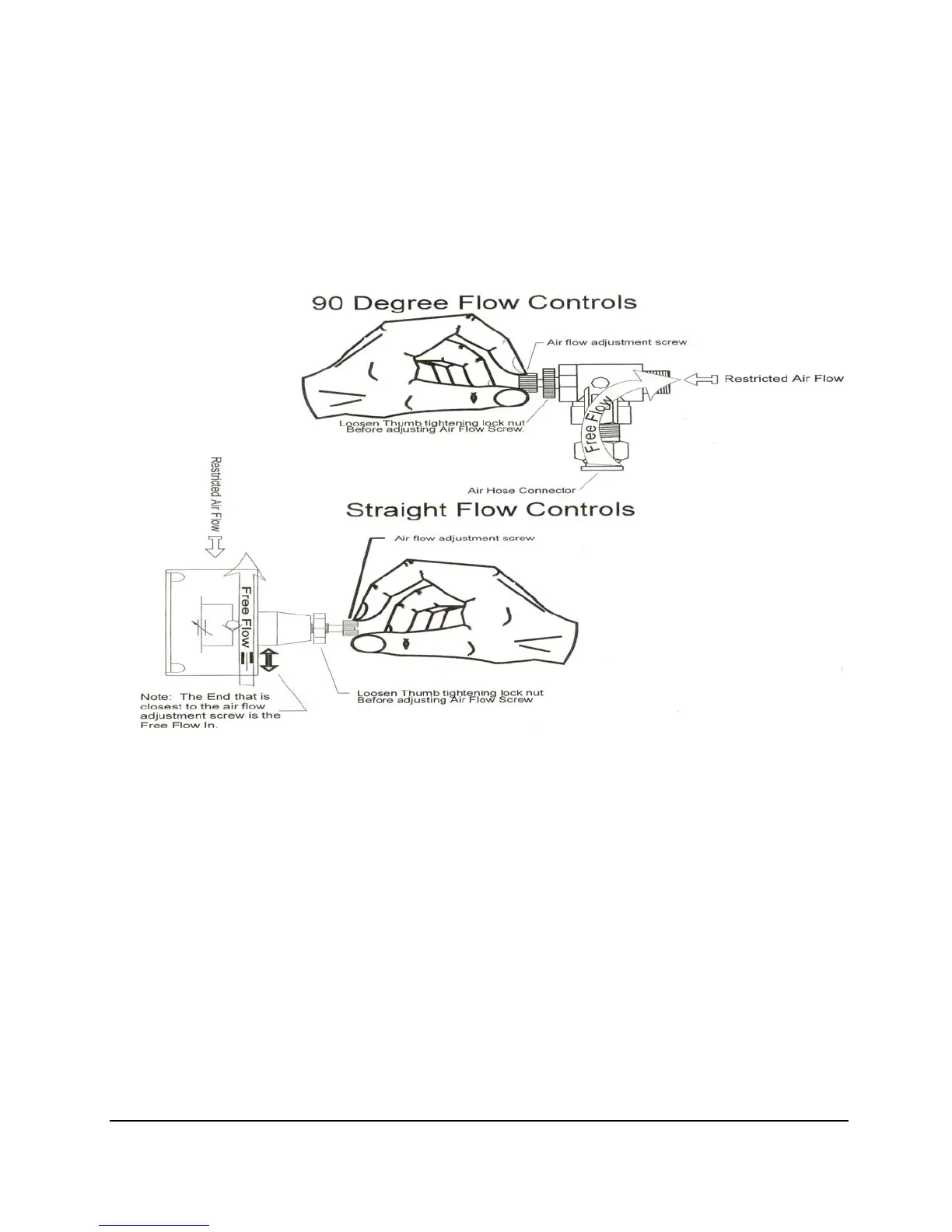

2. Check the flow controls to see that they are adjusted correctly and to the proper specifications.

3. Check for and obstructions to the cylinders such as screws or a misplaced tool etc… *

FOLLOW ALL SAFETY GUIDELINES AND SIGNS DURING THIS PROCESS.

4. Check the air valves:

The air valves can be manually operated by pushing the slotted button on the end of the valve.

If you wish to keep the valve open, the push button assembly can be removed using and open

ended wrench and inserting a 3/8” N.C. cap screw. DO NOT over tight when reassembling the

valve.

5. If the valve seems to be leaking, the seals may be dry or contaminated with water or it maybe

that the cylinder “O” rings are damaged and air is passing from one side to the other side of the

cylinder. It maybe is necessary to purchase a rebuild kit or a new cylinder.

6. If the valve is not receiving an electrical signal, see “Electrical Trouble Shooting” instruction.

It might be necessary to call in a specialist or check with KVAL customer service at 1-800-

553-5825

If an Air Leak is coming from an exhaust port on the air bank:

Loading...

Loading...