Contact Information and Troubleshooting 7-3

7.3 Maintenance alerts

During normal use, the Echo liquid handler may prompt that it needs

attention. Refer to the following maintenance alerts:

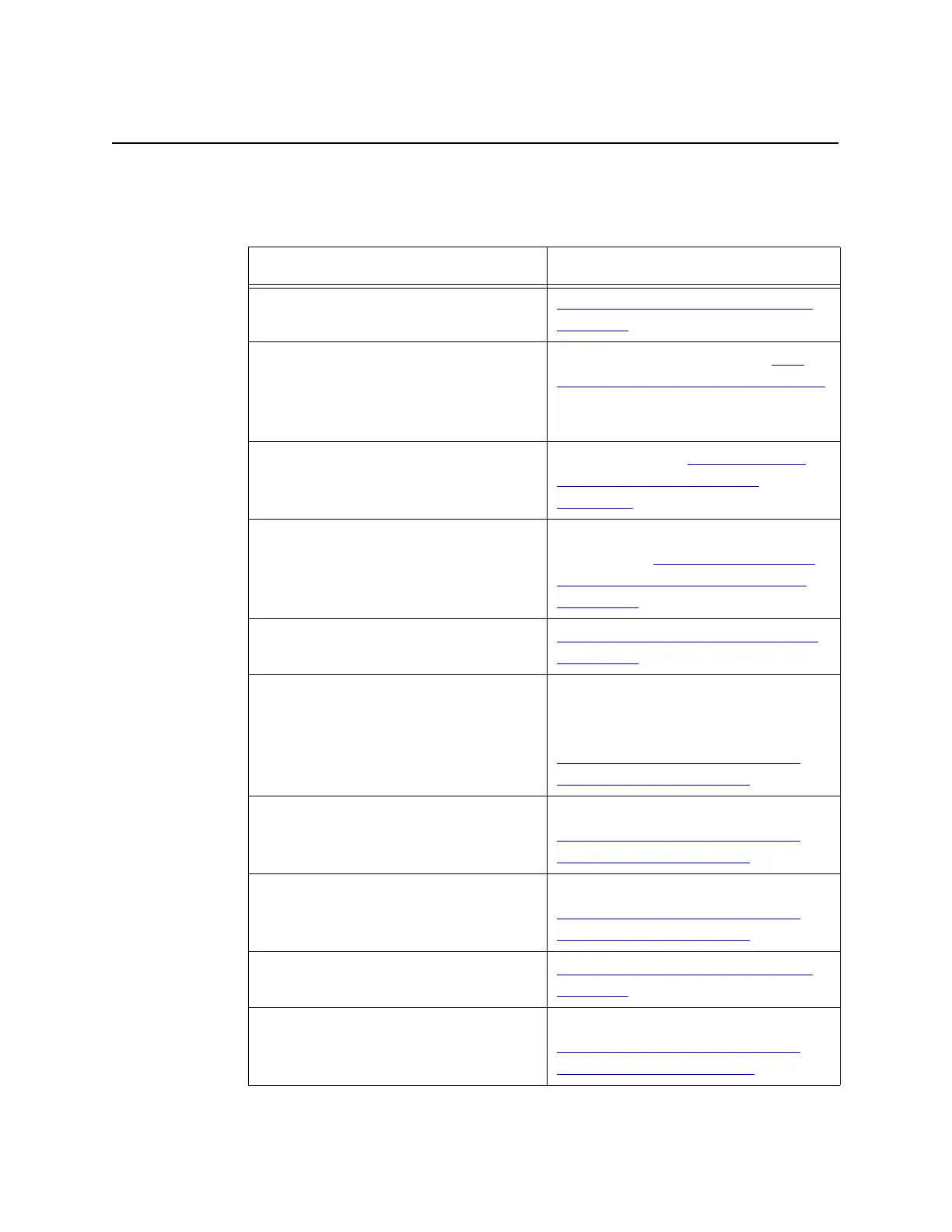

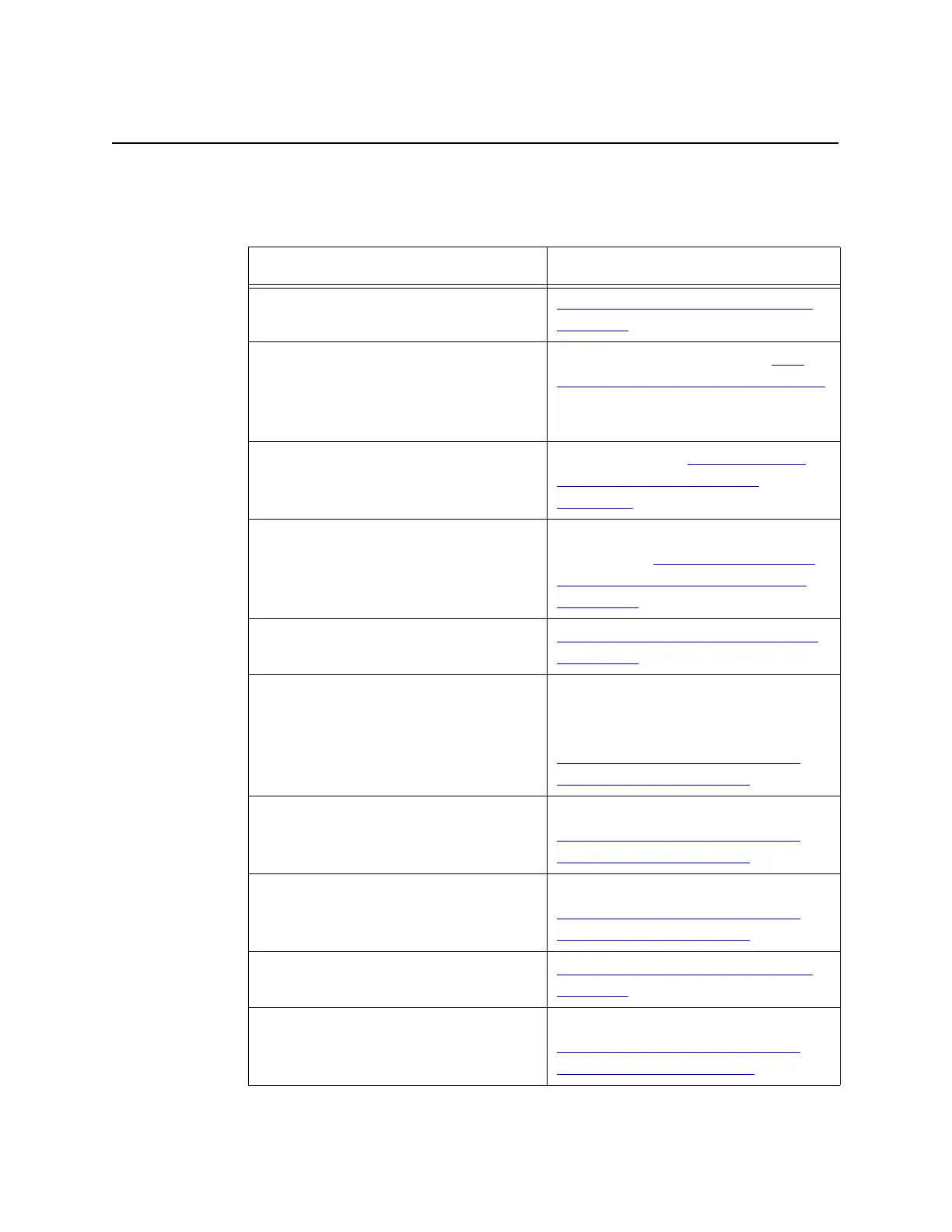

Table 7.1. Echo Maintenance Alerts

Maintenance Alert Procedure

Warning light is yellow. Possible

causes:

See “Status indicator lights” on

page 3-9.

The Echo stages (acoustic

transducer, source plate, and

destination plate) are not

homed.

Perform Home calibration. See

“Home calibration” on page 5-45.

The fluid level is low in the

coupling fluid bottle.

Add more fluid. See “Refill the

coupling fluid bottle” on

page 6-8.

The coupling fluid temperature

is outside of the normal range:

21.2°C–23.0°C

Check the chiller setting, it should

be at 22°C. See “Coupling fluid

temperature and indicator” on

page 5-36.

The waste water bottle is full

(on older systems only).

See “Waste bottle indicator” on

page 5-35.

The process door is neither fully

open nor fully closed.

Check for obstruction.

Check compressed air pressure,

it could be too low.

See “Compressed air pressure

indicator” on page 5-35.

The upper anti-static bar is

neither fully up nor fully down.

Check compressed air pressure.

See “

Compressed air pressure

indicator” on page 5-35.

The source plate dryer nozzle is

neither fully up nor fully down.

Check compressed air pressure.

See “

Compressed air pressure

indicator” on page 5-35.

Fault light is red. Possible

causes:

See “Status indicator lights” on

page 3-9.

The user-supplied compressed

air supply is low (< 70 PSI) or

nonexistent.

Increase air pressure.

See “Compressed air pressure

indicator” on page 5-35.

Loading...

Loading...