OPTIMIZER

TM

26

1.4 HYDRAULIC SYSTEM

MAINTENANCE

1.4.1 HYDRAULIC SYSTEM GENERAL

INSPECTION

HYDRAULIC SYSTEM GENERAL

INSPECTION PROCEDURE

• For new equipment, change the

return element filter after 50 hours

of use, and every 500 hours

thereafter. See hydraulic filter

replacement procedure section

1.4.9;

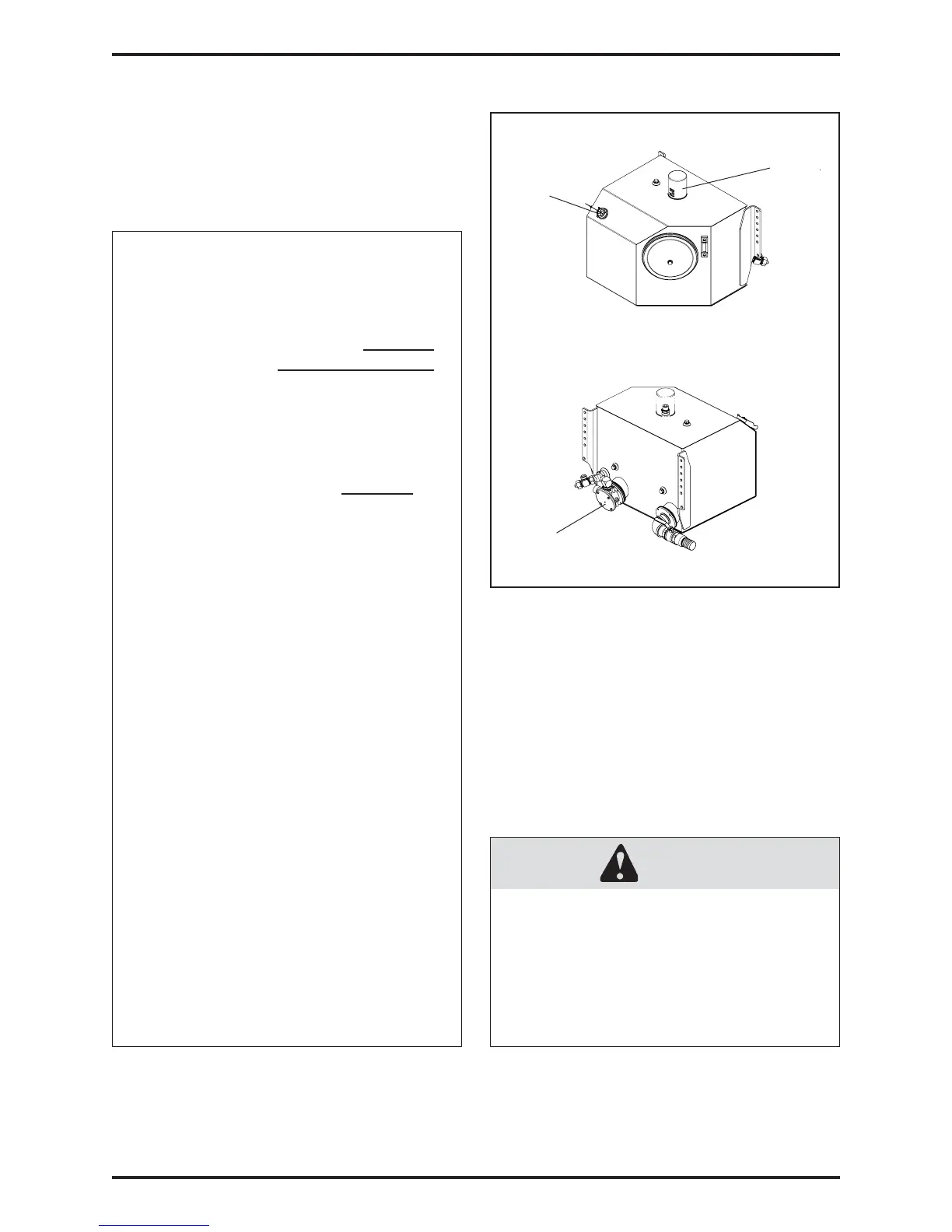

• Clean the strainer inside the

reservoir after the first 50 hours of

use and yearly thereafter (Figure

#1.16). See hydraulic strainer

cleaning procedure, sec.1.4.10;

• When maintenance is carried out,

protect the hoses from any dirt that

would eventually get into the oil;

• Periodically inspect and adjust the

oil pressure in the hydraulic system

as follows: 2500 PSI +/- 25 PSI@1500

RPM (2300PSI@700 RPM; idle

speed);

• Frequently inspect the hydraulic

lines and connections for leaks,

correct if necessary;

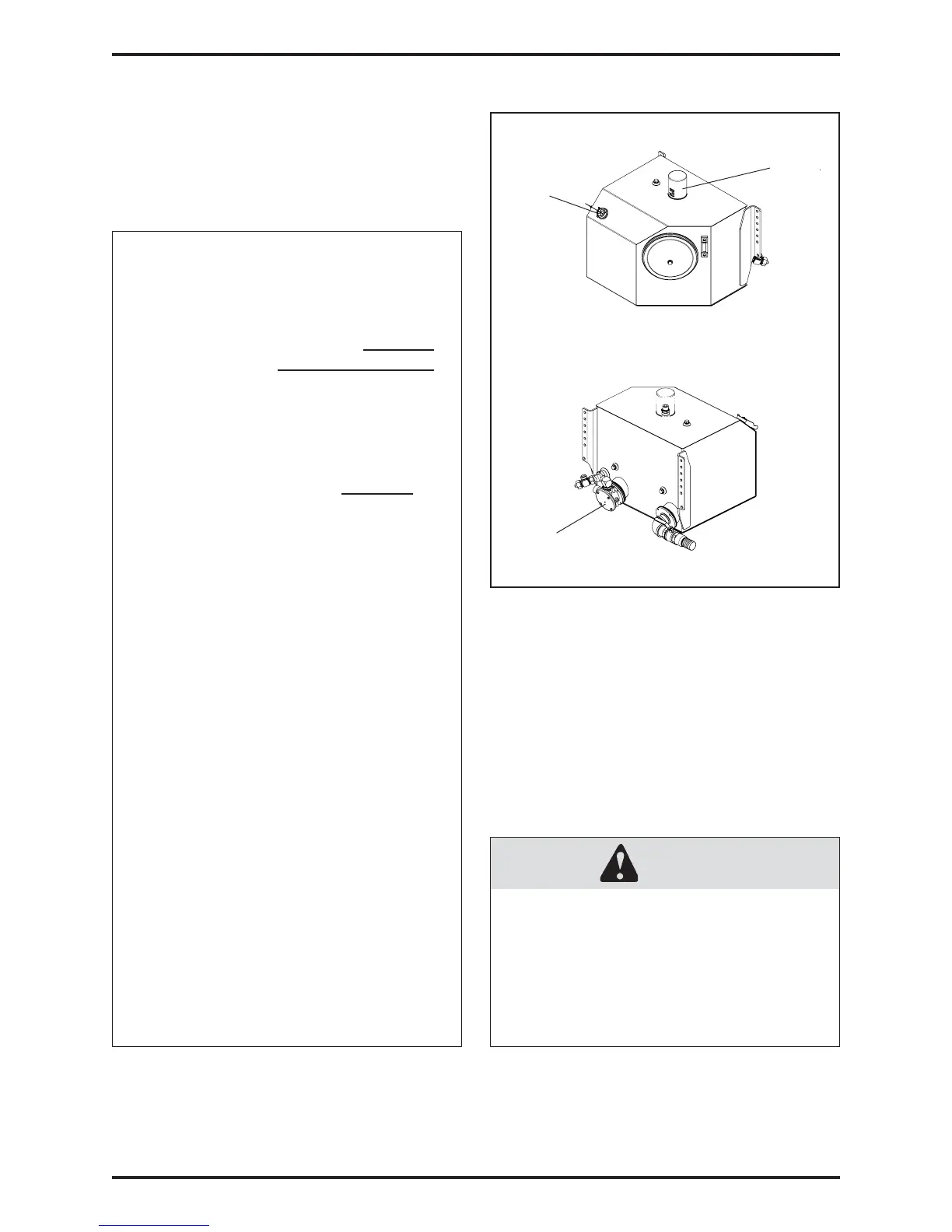

• The suction valve on the reservoir

must be fully open (Figure #1.1)

before starting the engine;

Filter/

breather

Filler

cap

FIGURE #1.16

HYDRAULIC TANK PARTS

Filter

1.4.2 MAIN RELIEF VALVE PRESSURE

ADJUSTMENT

A hydraulic oil pressure verification must be

performed every month. The relief valve is

preset to 2500 PSI +/- 50 PSI at 1500 RPM

by the manufacturer. If the pressure is not

within this preset adjustment, the pressure

relief valve must be readjusted.

ADJUSTING THE MAIN RELIEF

VALVE AT HIGHER PRESSURE

THAN 2500 PSI WILL CREATE

EXTENSIVE DAMAGE AND VOID

THE MANUFACTURER’S

WARRANTY.

CAUTION

Loading...

Loading...