OPTIMIZER

TM

56

3.3 TAILGATE LOCKING MECHANISM TROUBLESHOOTING

The tailgate locking mechanism is equipped with hydraulic safety systems that prevent

accidental unlocking of the tailgate during operation. One of the systems is the velocity fuse

with the “power bleed” and the other is the holding valve.

The spool inside the tailgate section of the valve is designed in such a way, that it will allow

pressure to pass through it each time the pressure is building up in the hydraulic system (i.e.:

when the packer is working). The pressure “burst” goes to the holding valve into port “D1”

and then out to the cylinder by port “U1”. This will keep the tailgate cylinders pressurized and

the tailgate closed when packing material.

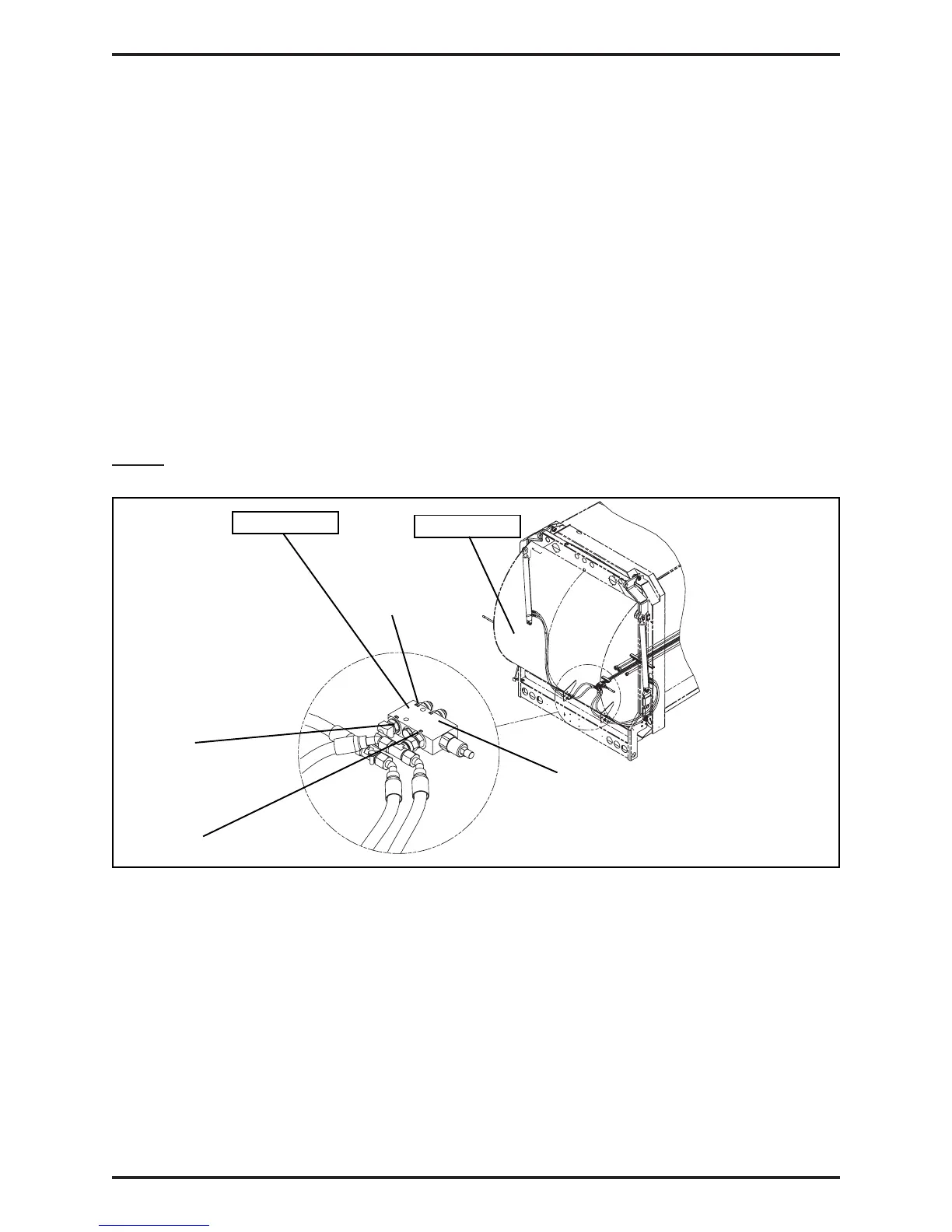

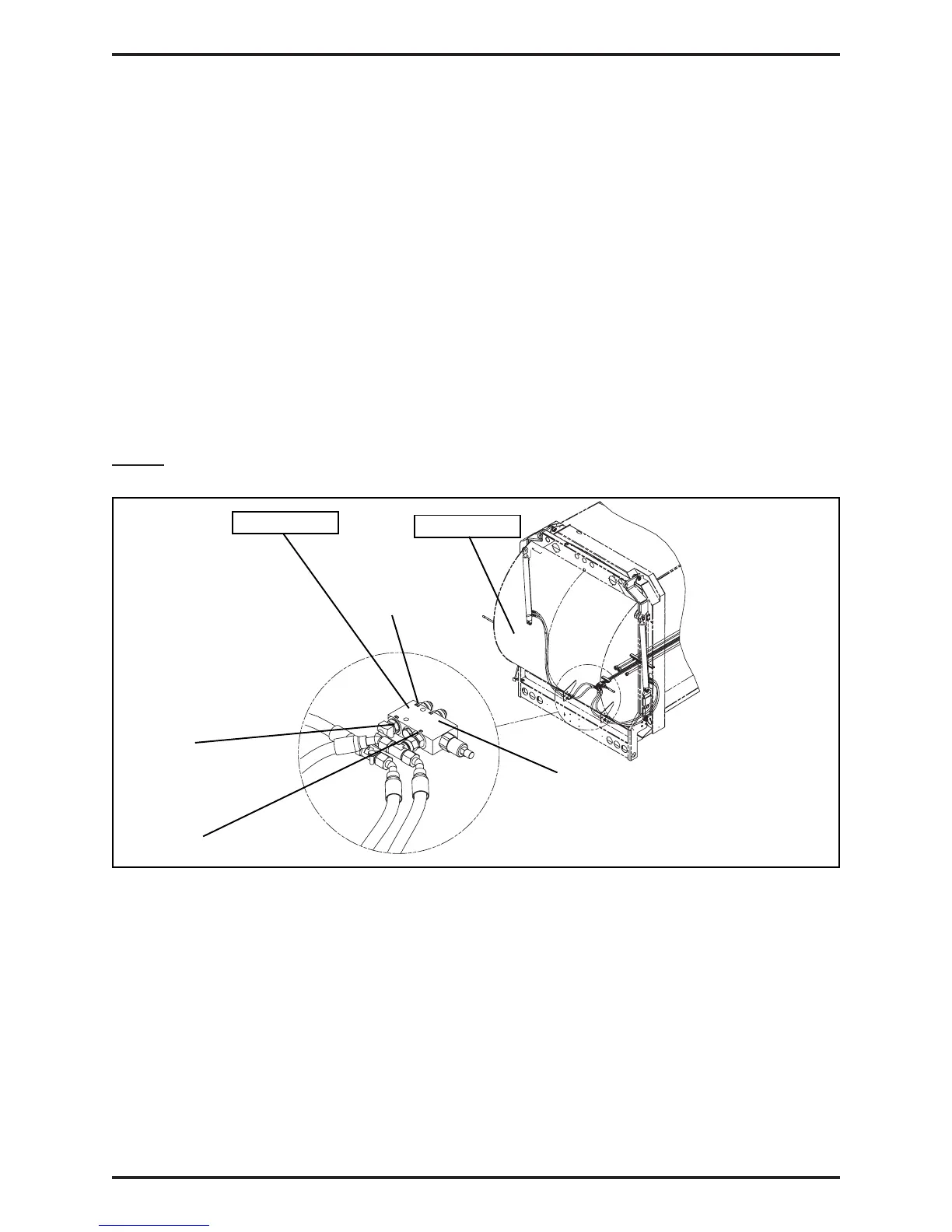

The velocity fuse, located on the valve (Figure #3.3), will make sure to drain any slow moving

oil coming from the piston side of the tailgate cylinders. Since the rod side is being pressurized

with the “Power bleed” system, the other side has to drain to avoid any pressure build-up.

The velocity fuse makes the piston side open to tank when the oil is moving under 3 gallons

per minute and will shut when a flow signal is sent.

NOTE: Refer to the main hydraulic schematic.

Holding valve

Tailgate

Port

U2

Port U1

Port D1

Port D2

FIGURE #3.2

Loading...

Loading...