31

MAINTENANCE

10. Clean inside the hydraulic tank

with a clean and dry cloth in order to

remove any metal particles or debris

accumulated at the bottom.

• To clean the interior of the an

aluminum tank (cylindrical), insert

the hand in the hole where the

strainer was fixed. This allows to

clean one half of the tank. To clean

the other half, remove the entire

filter at the rear side of the tank,

insert the hand inside, and clean

with the cloth.

• To clean the steel tank (Figure

#|1.16), remove the access panel by

removing the retaining screw. Insert

the hand inside and clean the interior

with the dry and clean cloth.

11. Change the return filter element

(twice a year).

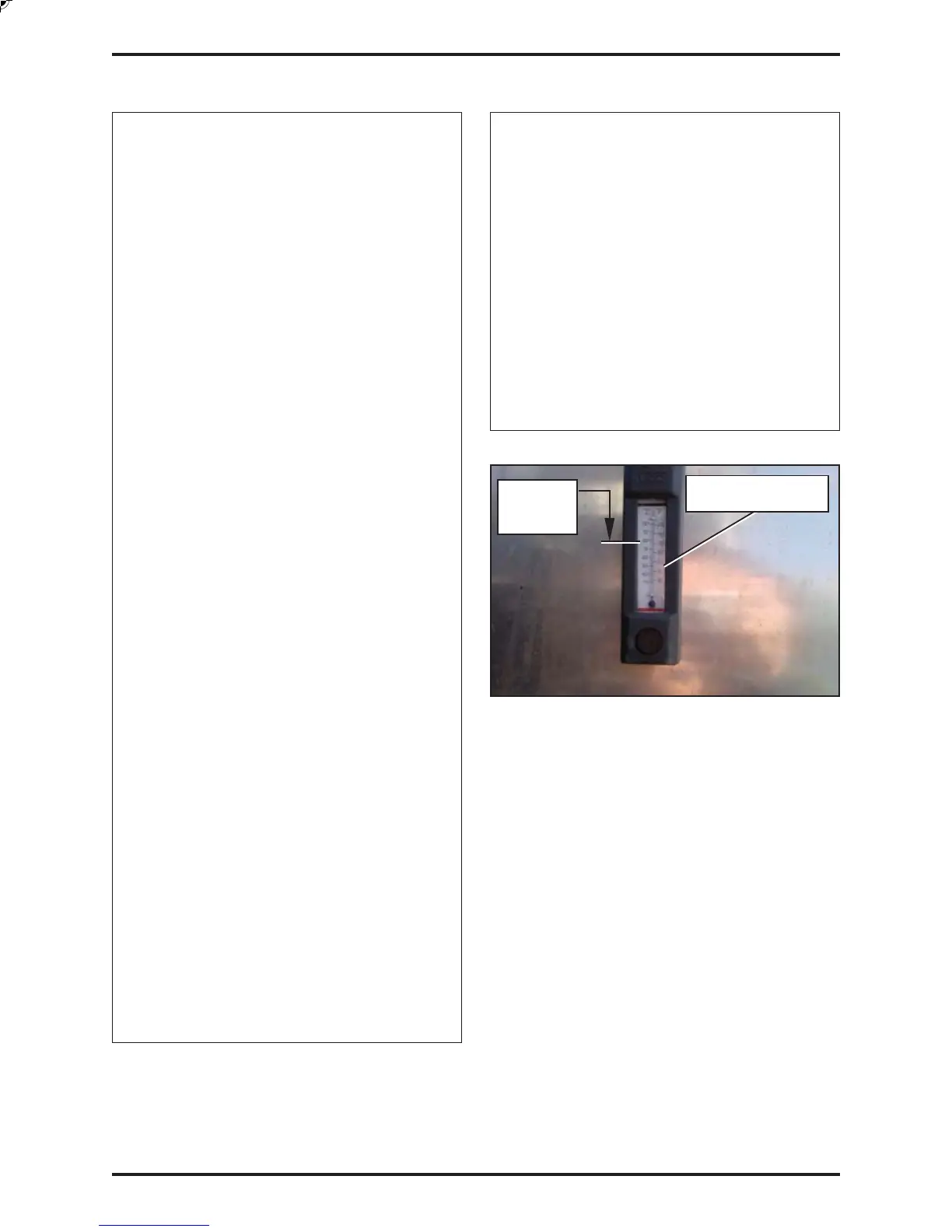

12. Refill the tank until oil reaches

the 3/4 of the oil gauge (Figure #1.20).

Use a high quality oil, that has good

performance in cold weather(if

applicable), such as SHELL TELLUS

T32 or equivalent (See “Lubrication”

section for specifications). The

whole system will require between

50 and 60 gallons.

13. The oil must be clean and free of

any dirt, metallic particles or sand

etc.) The use of a filtering screen is

strongly recommended while filling

the tank with new oil.

14. If the suction line has been

replaced, fill the line until the oil

reaches the pump to avoid cavitation

(see section 3.1 of Troubleshooting).

15. Start the engine and check again.

OIL GAUGE

AND TEMPERATURE

3/4 OF OIL

LEVEL

GAUGE

FIGURE #1.20

HYDRAULIC OIL

REPLACEMENT PROCEDURE (Cont’d)

Loading...

Loading...