April 8, 2011 HN FAQ Memo, Version 2.0 Page 59 of 108

3.3.3 C200 and HN cleaning sequence.

The cleaning of the parlour milking system will be changed when the HN is installed.

The princip of the changed cleaning process is that the Shutoff valves will be used to alternate

between letting the vacuum through the milking clusters and through the HN samplers. This is

done to ensure sufficient vacuum supply in both milking clusters and samplers during the

cleaning process.

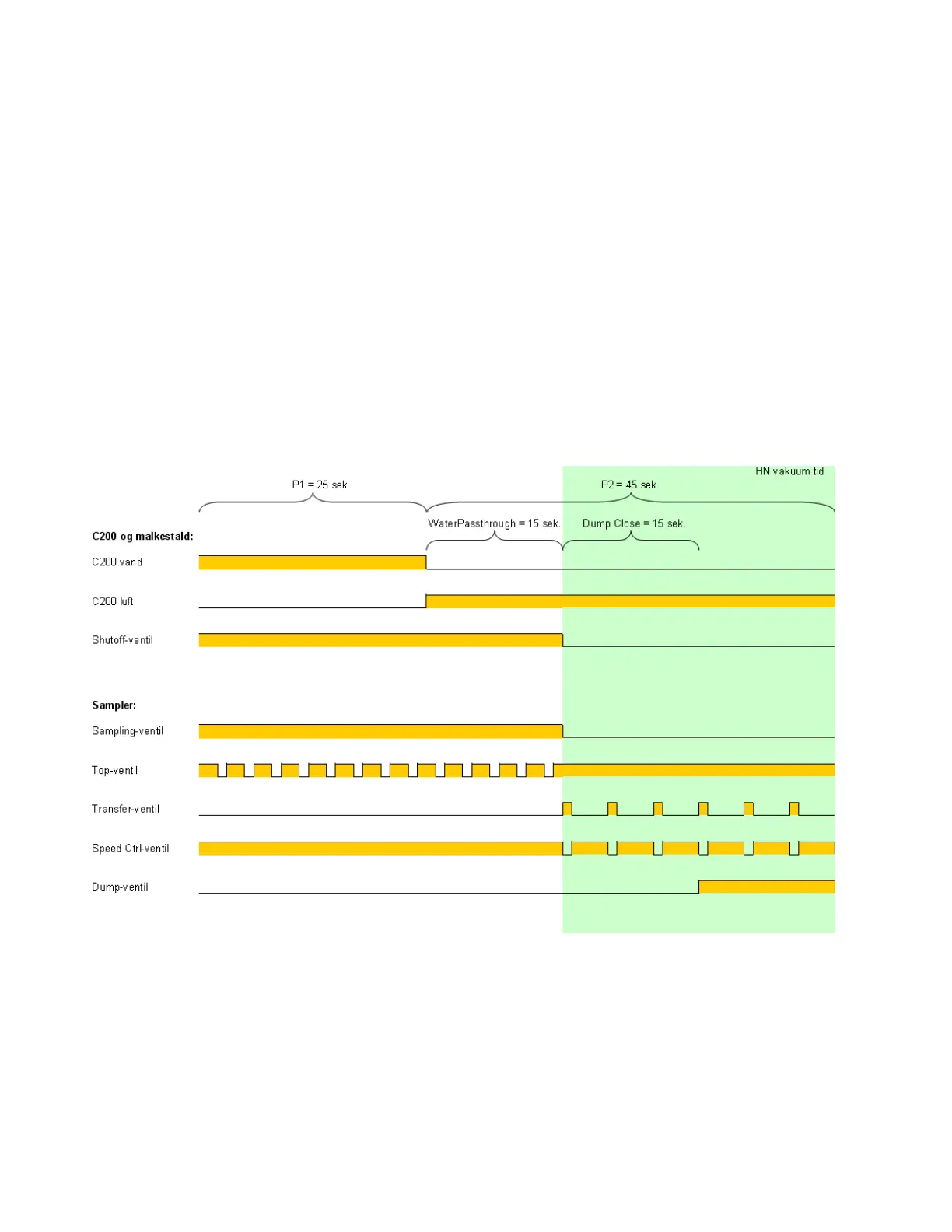

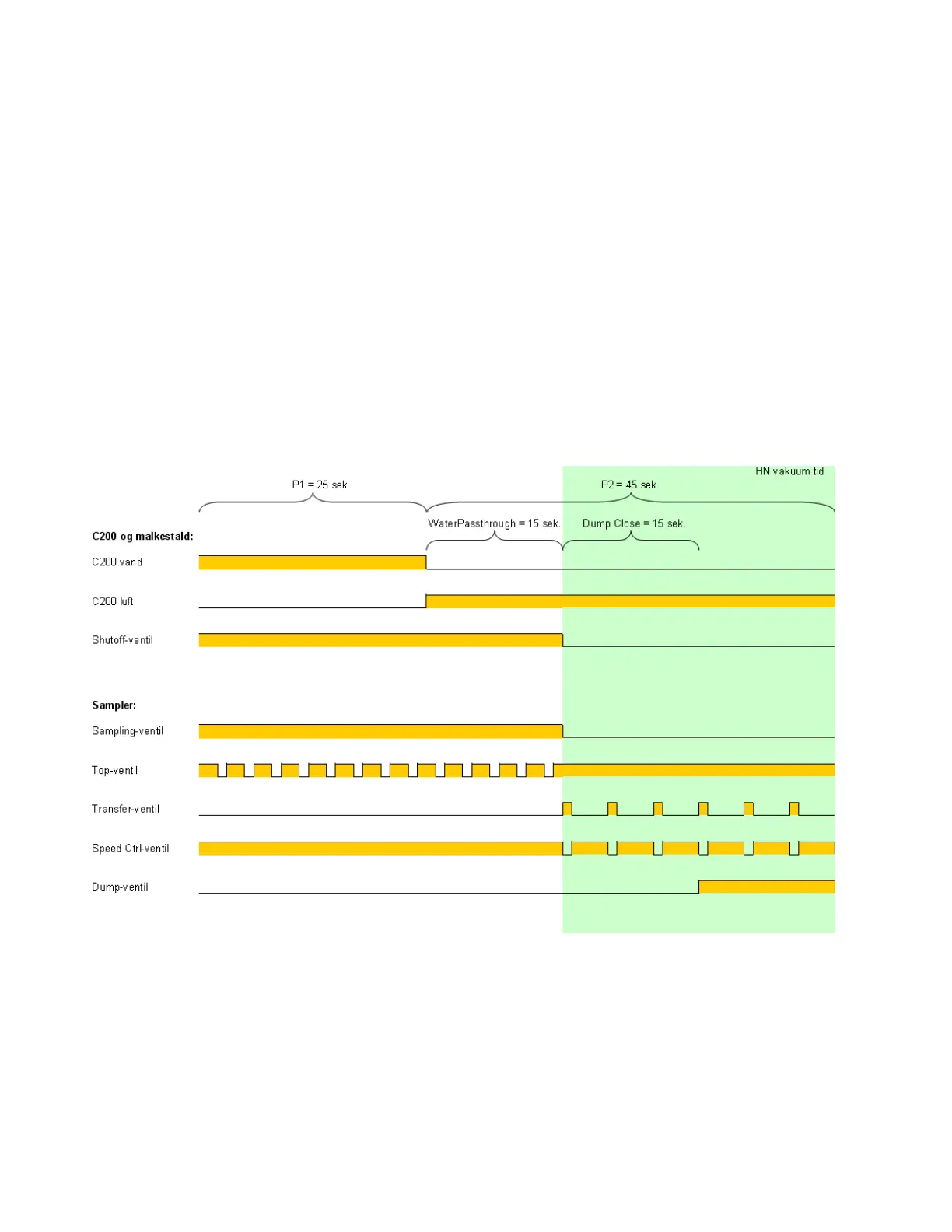

In figure 2 the sequence created by the parameters P1 and P2 during the cleaning is illustrated.

The timing of the C200 Air valve, the Shutoff valves and the valves in the Samplers during this

sequence are shown.

This sequence is repeated several times during both prerinse, finalphase and circulation

cleaning. To ensure that the samplers have enough cleaning time with all vacuum (shutoff valve

turned off) P2 has to be increased with minimum 30 sec.

The total cleaning time off the C200 shall be increased equivalent to ensure the same

cleaning time of the parlour as without the HN installed.

Refer to the table below for description of all the relevant parameters.

Figur 2. Timing for C200 Air valve,, Shutoff-valves and Sampler valves..

Loading...

Loading...