What to do if receiver is set on C1 and transmitter on C2 for Leuze electronic MLC 520 Security Sensors?

- KkentayalaSep 8, 2025

Set the transmitter and receiver on the same transmission channel and align both correctly.

What to do if receiver is set on C1 and transmitter on C2 for Leuze electronic MLC 520 Security Sensors?

Set the transmitter and receiver on the same transmission channel and align both correctly.

How to troubleshoot OSSD error, source unknown in Leuze electronic MLC 520 Security Sensors?

Check the wiring. Replace the cable and the receiver if necessary.

What to do if alignment is incorrect or protective field interrupted in Leuze electronic Security Sensors?

If the alignment is incorrect or the protective field is interrupted, remove any objects obstructing the protective field. Ensure the transmitter and receiver are correctly aligned, or reposition any blanked objects to their correct size and position.

What to do if there is a short circuit against GND at OSSD2 in Leuze electronic MLC 520?

Check the wiring. Exchange the cable, if applicable.

What to do if there is short circuit against +24 V at OSSD1 in Leuze electronic MLC 520?

Check the wiring. Exchange the cable, if applicable.

What to do if there is short circuit against GND at OSSD1 in Leuze electronic MLC 520 Security Sensors?

Check the wiring. Exchange the cable, if applicable.

How to fix high-impedance short circuit to VCC OSSD2 in Leuze electronic MLC 520?

Check the wiring and replace the cable if needed.

How to fix high-impedance short circuit to VCC OSSD1 in Leuze electronic MLC 520 Security Sensors?

Check the wiring and exchange the cable, if necessary.

What to do if the operating mode changed for Leuze electronic MLC 520?

Check the wiring and restart the sensor.

What to do for internal fault in Leuze electronic MLC 520 Security Sensors?

If a restart fails, replace the device.

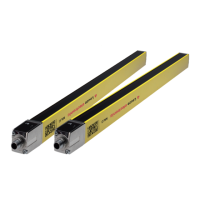

| Brand | Leuze electronic |

|---|---|

| Model | MLC 520 |

| Category | Security Sensors |

| Language | English |

Defines correct usage and potential misuse of the safety sensor to ensure safe operation.

Outlines the qualifications and responsibilities of personnel involved with the safety sensor.

Details the safety responsibilities of machine manufacturers and operating companies.

Explains the mandatory safety function for preventing unintended restarts after interruptions.

Describes the function for monitoring external contactors for safety.

Describes using the sensor for hand/finger protection at machine operation points.

Guidelines for positioning the transmitter and receiver for correct operation.

Formula and parameters for calculating the required safety distance according to EN ISO 13855.

How to calculate safety distance for different approach directions.

Specific calculation for safety distance in access guarding scenarios.

Formula for safety distance when accessing the protective field from above.

Calculation for parallel approach in danger zone guarding.

Guidelines on maintaining distances to reflective surfaces to prevent false triggers.

Methods to prevent optical crosstalk and interference between multiple sensors.

Details the pin assignments for transmitter and receiver connectors.

Details the pin assignments and connection diagram for the MLC 520 receiver.

Illustrates a typical circuit diagram for connecting the MLC 520.

How to safely unlock the start/restart interlock after interruptions.

Tests required before initial use and after modifications to the system.

A checklist for integrators to verify proper installation and setup.

Periodic testing requirements for qualified personnel to ensure reliability.

Regular function checks to be performed by trained operators.

General guide for diagnosing and resolving device failures using indicators.

Technical data related to safety standards like PL, SIL, and category.