11. Press the pump casing into the Reinforcement

Ring, mount the Axial Support Plate and add

the two Semi Fixation Rings.

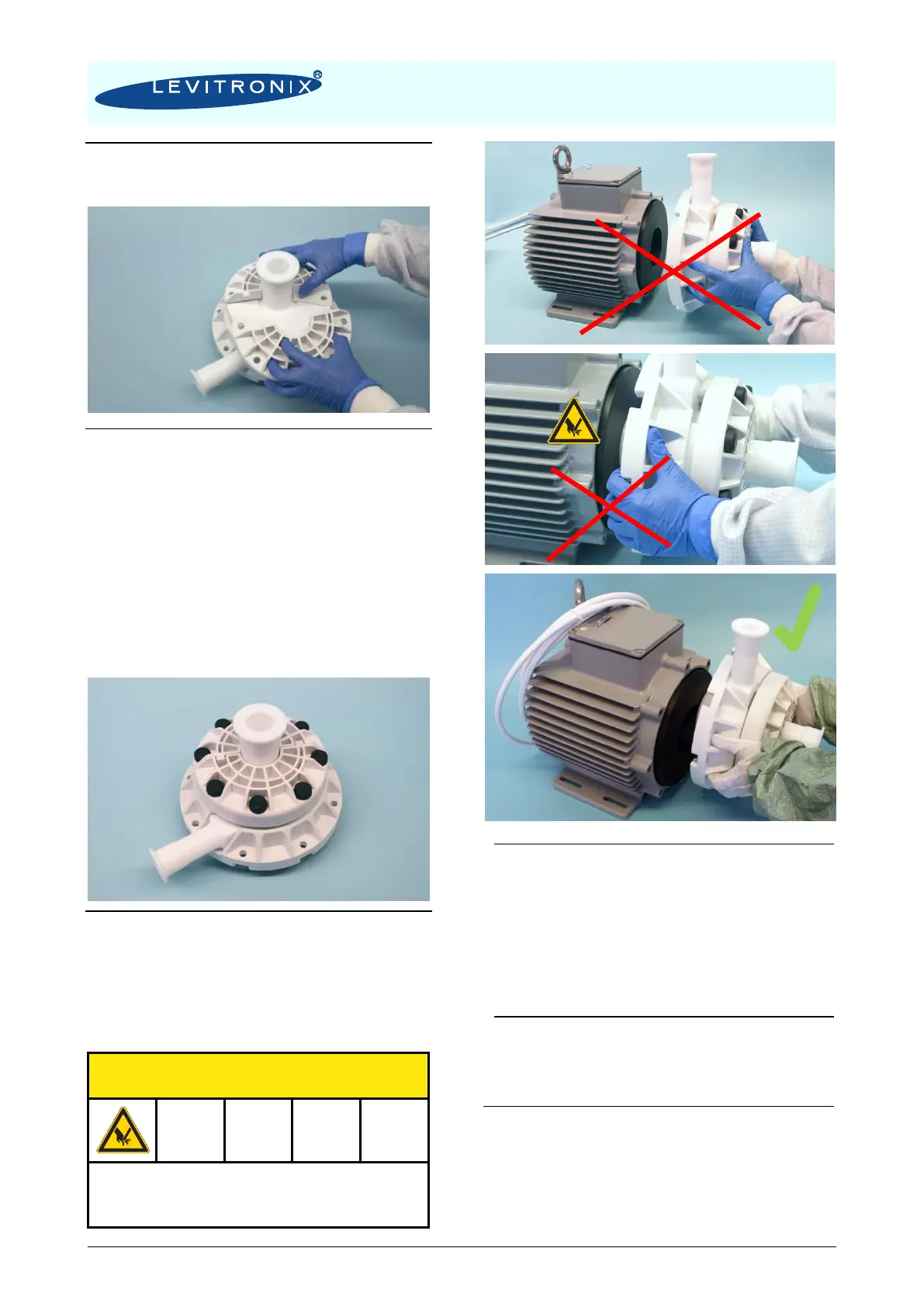

12. Tighten the 8 Pump Mounting Screws (with

the relevant washers) crosswise and

symmetric regular on the semi fixation rings

and add the Protective Screw Covers. The

screws should not be used to press the lid

with the O-ring into the bottom of the pump

casing. Do not apply too much torque. The

torque specifications are:

Recommended torque for Pump Mounting Screws:

Stainless Steel M10: 150 Ncm

(PVDF M10: 100 Ncm)

Note: These are typical values for the standard pump head

LPP-4000.5. Refer to the relevant pump head specification drawings

for other configurations, which may have different values.

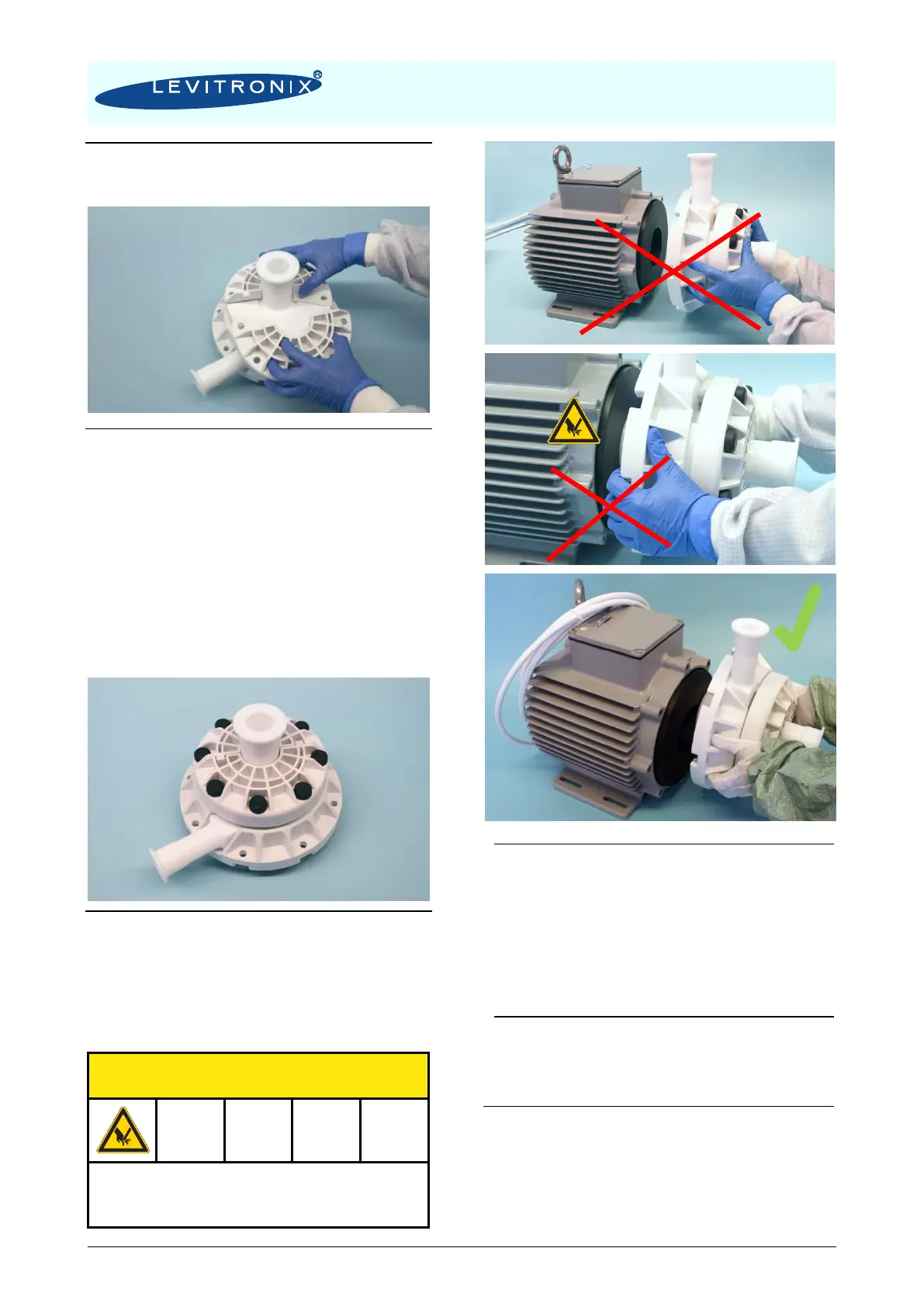

13. Insert the pump casing to the motor by placing

the bottom of the pump head on the side of

the motor cup and move it afterwards to the

center until the pump head locks in. Do not

directly insert the pump head to the center of

the motor as the fingers could be squeezed by

the magnetic forces.

Take care of your fingers. Hold the pump head

on the outer side and not on the bottom

because of risk to get the fingers squeezed.

14. Mount the pump head with the 8 Motor

Mounting Screws crosswise and symmetric

on the motor. Do not apply too much torque.

The torque specification is:

Recommended torque for pump motor screws:

PTFE coated stainless steel M10: 120Ncm

Note: These are typical values for the standard pump head LPP-

4000.5. Refer to the relevant pump head specification drawings for

other configurations, which may have different values.

15. Start the system and check if the Impeller is

rotating properly and the pump head doesn’t

leak.

16. If the pump head leaks, check and make sure

that the Pump Casing Lid and the O-Ring are

properly pressed into the Pump Casing

Bottom. It may be necessary to change the O-

Ring if it has been damaged.

Loading...

Loading...