User Manual for PuraLev

®

600MU

www.levitronix.com

PL-4033-00, Rev09, DCO# 20-144

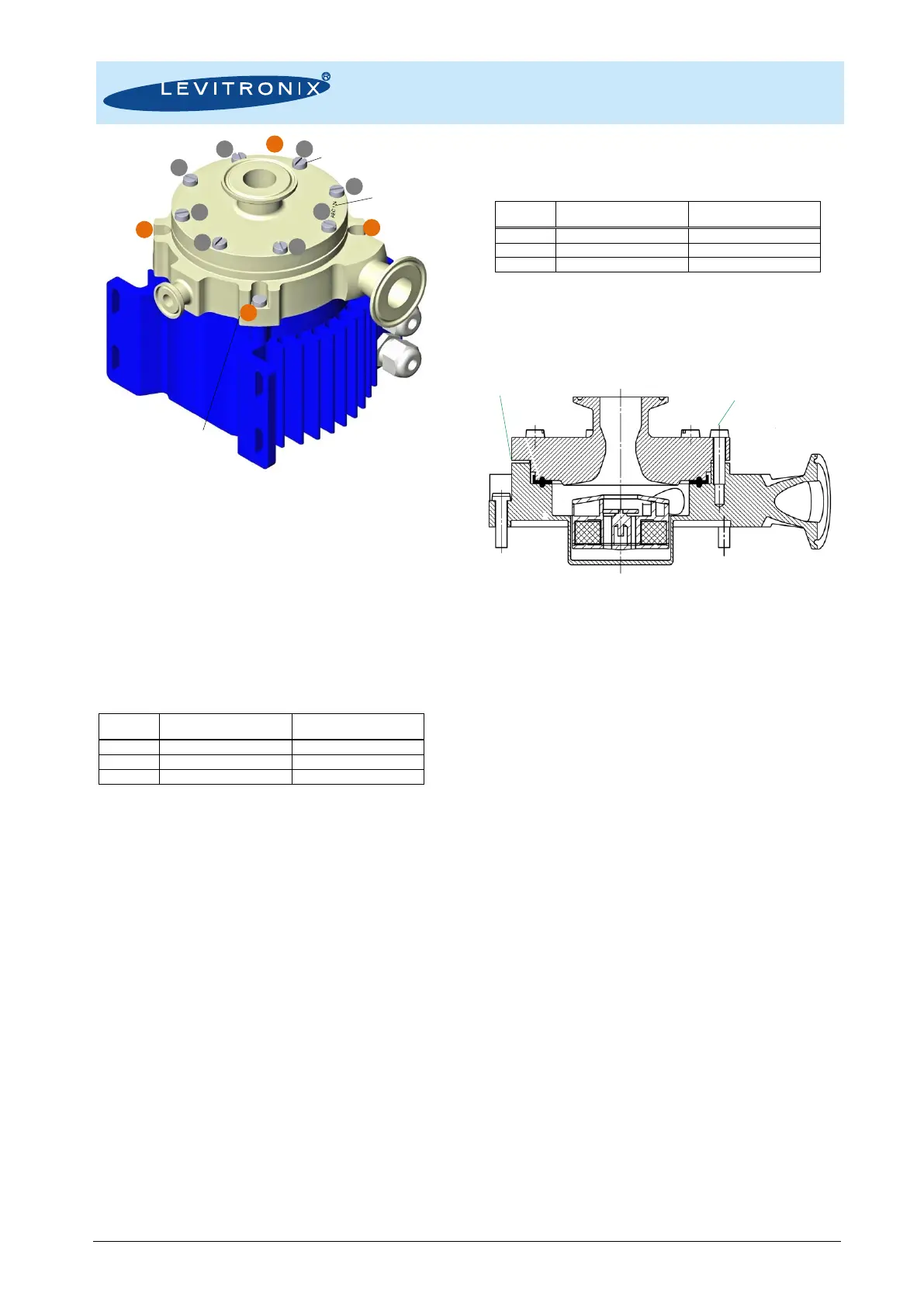

Figure 38: Screws of pump head (Stainless Steel INOX A4)

6.3.4 Insertion and Fixation of New Pump Head

Assure that on the new pump head the Fixation Disk is

not attached anymore. Then insert the pump head

smoothly into the motor. Rotate it until the pump head

holes and the motor threads are aligned.

6.3.5 Fixation of New Pump Head to Motor

Tighten the Screws M1 to M4 in the order as numbered in

Figure 38. Use sequences with incremental torque steps

in order to avoid fixing the pump head asymmetrically to

the motor.

Torque for LPP-600.7/18

(PVDF Hous.)

Torque for LPP-600.27

(SS Housing)

6.3.6 Start-Up and Functionality Check

Start up the system and check if the impeller is rotating

properly. If the pump is not operating as expected, make

sure that the metallic Fixation Disk or another magnetic

part has not accidentally attached itself to the bottom of

the pump head.

6.4 Re-Assembling of Pump Head

If possible, avoid disassembling the pump head. If this is

not avoidable, for example due to cleaning reasons, use

the following instructions to re-assemble a pump head.

6.4.1 Insertion of Impeller and Sealing

Insert the Impeller into the Housing Bottom and then

insert the Sealing into the relevant cavity (see Figure 36).

6.4.2 Press the Lid into the Housing Bottom

Press the Housing Lid in to the Housing Bottom. Do not

use the pump screws for doing this.

6.4.3 Tighten the Pump Head Screws

Tighten the pump head screws P1 to P8 in the order as

numbered in Figure 38. To avoid an asymmetric lid to

bottom alignment, use sequences with torque increments

until each screw is tightened according to the following

table:

Torque for LPP-600.7/18

(PVDF Hous.)

Torque for LPP-600.27

(SS Housing)

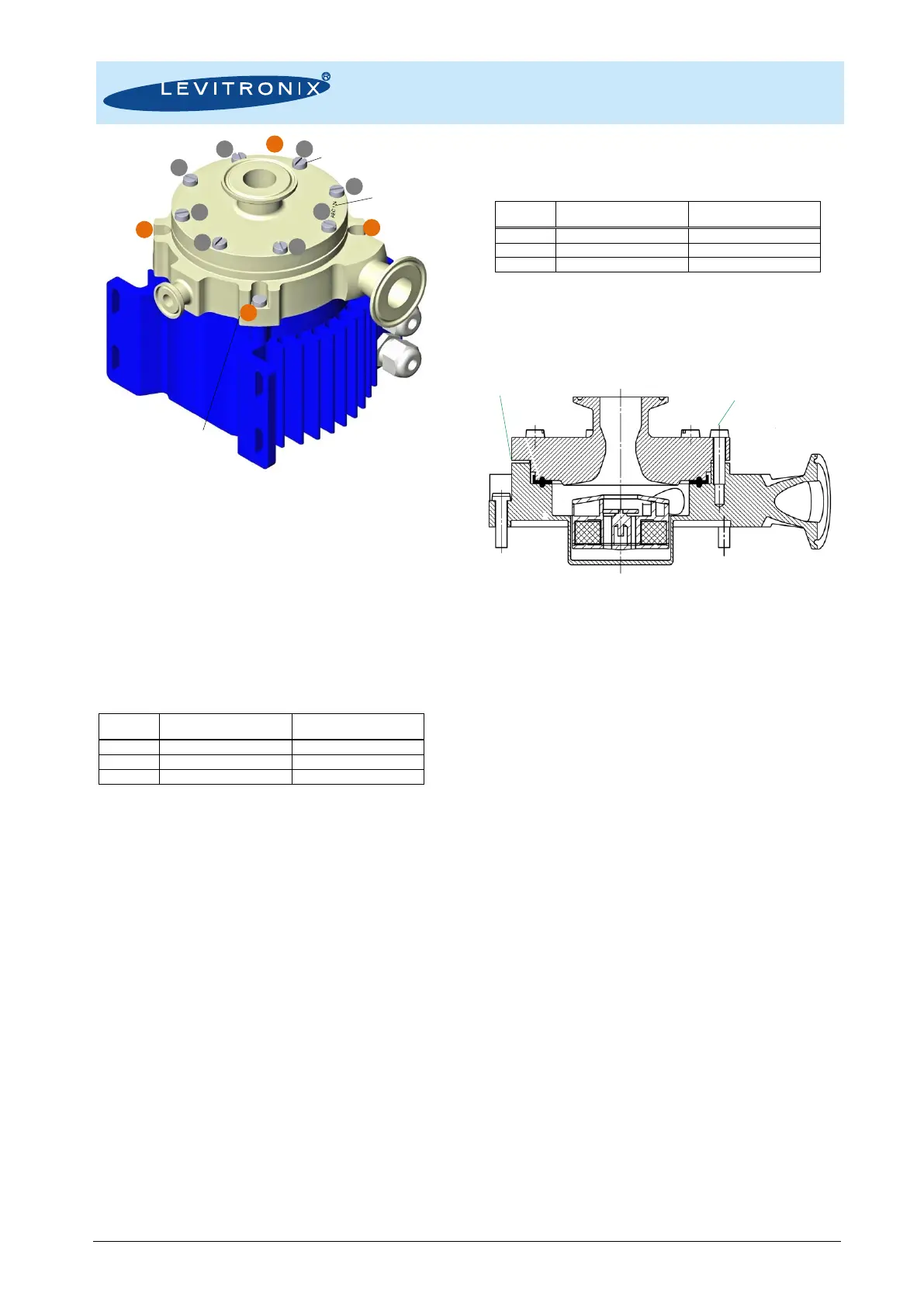

6.4.4 Final Assembly Check

Check the uniformity of the gap between lid and bottom

and that all screws are tightened properly.

Figure 39: Cross-section of pump head with check points

6.5 Assembly into a Circuit

The following points shall be considered, when integrating

the pump head into a hydraulic circuit.

6.5.1 Usage of Fixation Disk

During handling, assembling and transportation of the

pump head with the hydraulic circuit it is recommended to

attach the Fixation Disk to the pump head bottom. This

fixes the impeller mechanically and reduces the magnetic

fields, which can attract other magnetic parts during

handling, sterilization and transportation.

6.5.2 Careful Handling of Multiple Pump Heads

Take care to the magnetic forces of the impellers when

handling multiple pump heads at the same time. Avoid

two pump heads coming together with force due to the

magnetic attraction, which might cause cracks.

6.5.3 Avoidance of Mechanical Stress

Do not apply too much bending forces to the fittings of the

pump heads LPP-600.7/18. It is recommended to use

3-way clamps (not 2-way) to attach stainless steel fittings.

This reduces the tendency to distort the PVDF fittings due

to different expansion coefficients of plastics and steel.

6.6 Maintenance

6.6.1 Check of Pump Head Screws

From time to time and specifically after heat treatments

like steam sterilization or autoclaving it is recommended

to check if the pump head screws still are screwed on

properly in order to assure proper of the pump housing.

6.6.2 Check of Sealing Property

The pump head design has recesses between lid and

bottom, which allow to seeing leakages immediately.

Regularly check these recesses for liquid leakage.

4x M6x25mm

(Screws M1-M4 for fixation of

pump head on motor)

8x M6x25mm for LPP-600.7/18

8x M6x12mm for LPP-600.27

(Screws P1-P8 for fixation of housing)

8x M6x25mm for LPP-600.7/18

8x M6x12mm for LPP-600.27

(Screws P1-P6 for fixation of housing)

Circular uniform gap of approximately

1.5 mm for pump heads LPP-600.7/18.

0.125-0.325 mm for pump head LPP-600.27.

Loading...

Loading...