6.7 Precautions for Autoclaving and SIP (Steam-In-Place)

When autoclaving the plastics pump heads LPP-600.7/18 the, Autoclaving Reinforcing Tool ART-600.1 (see

Figure 2 and Table 4) shall be used to minimize distortion effects of the plastics pump housing cup during

exposure to higher temperatures.

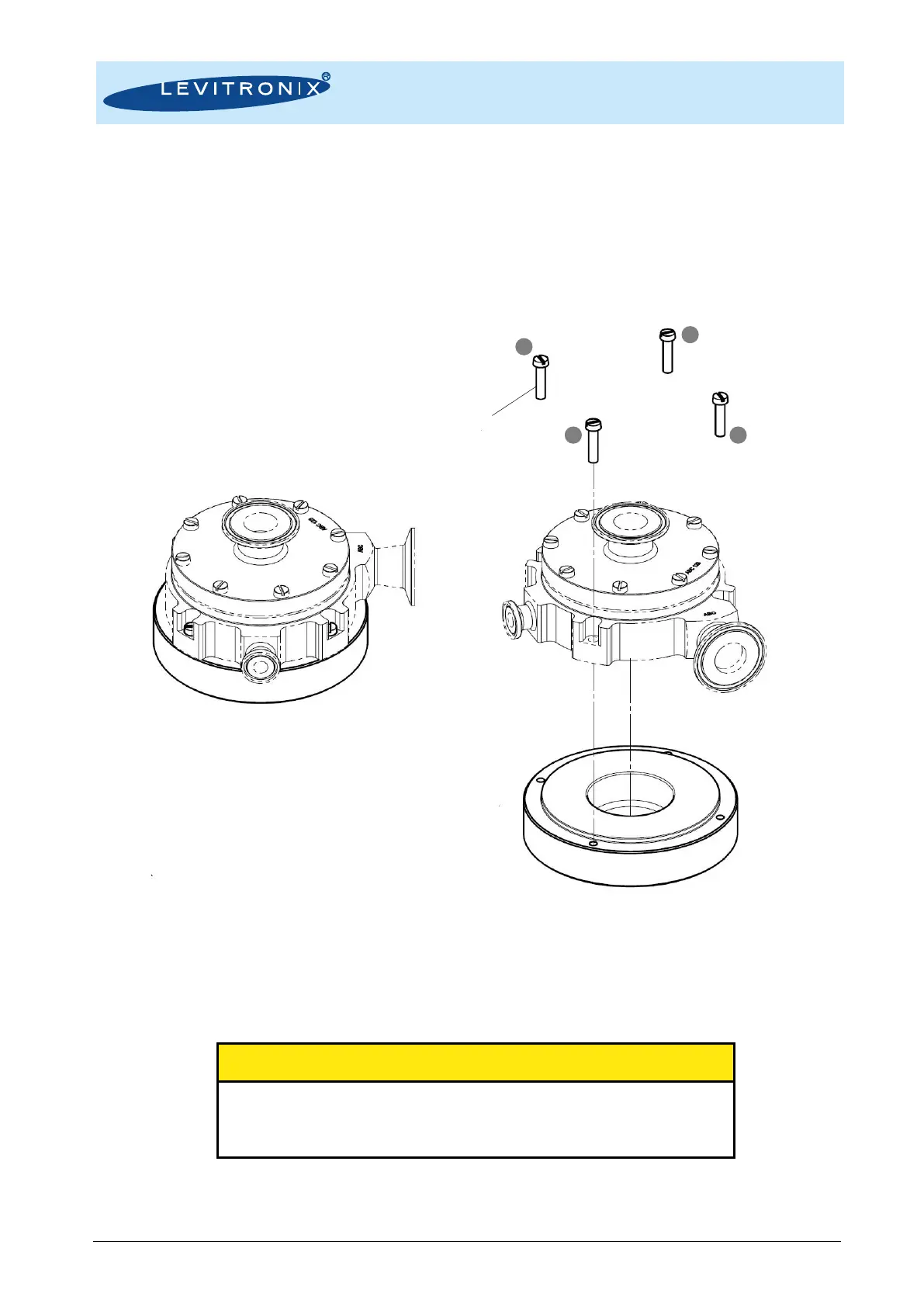

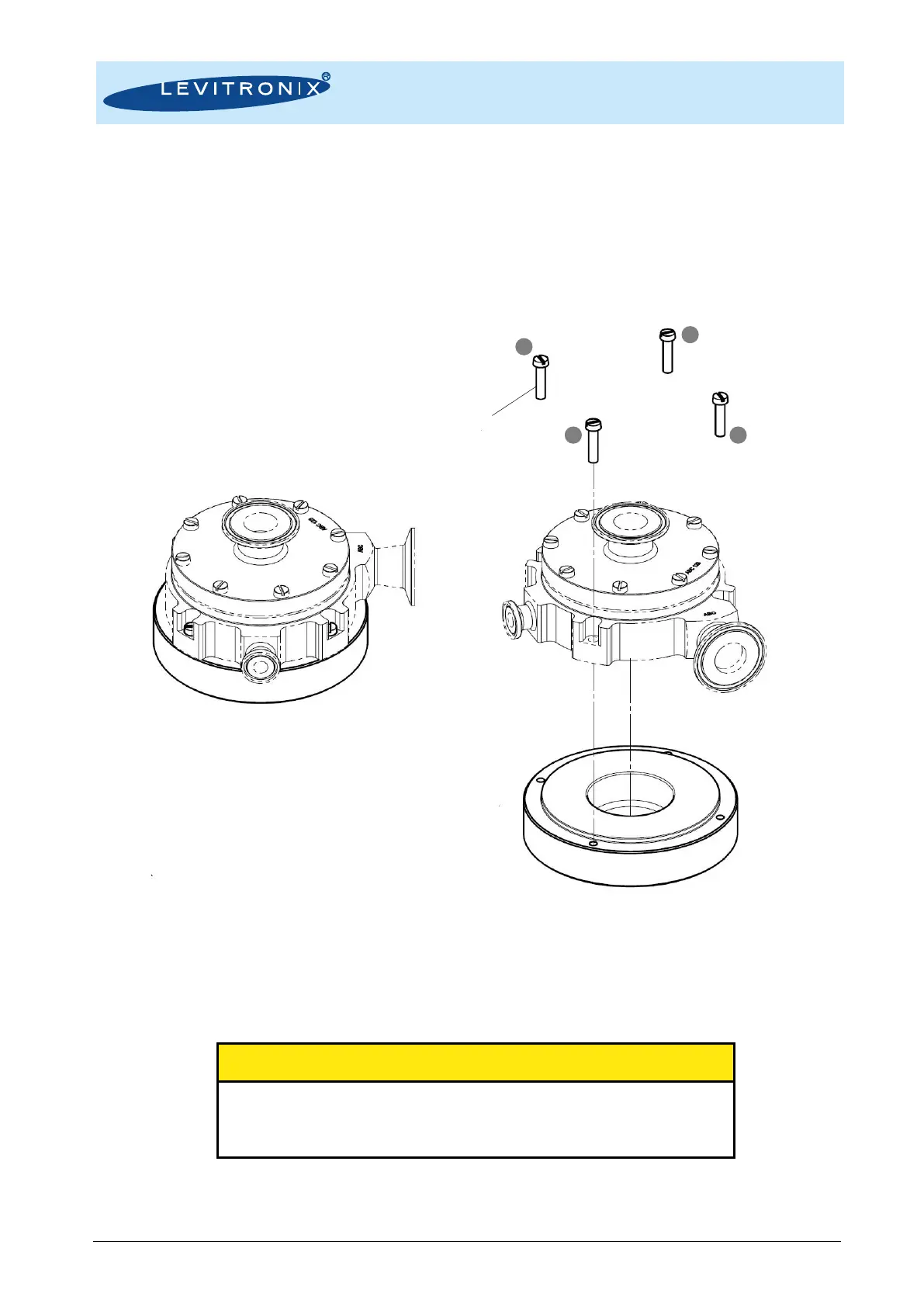

Figure 40 illustrates the mounting of the pump head on to the ART-600.1. The pump head shall be fixed with

4 screws according to the same procedure as described in Section 6.3.5.

Figure 40: Mounting of Autoclaving Reinforcing Tool ART-600.1

(For plastics pump heads LPP-600.7/18)

After autoclaving or SIP (Steam-In-Place) it is recommended to check the pump housing screws and uniformly

re-tighten them according to Section 6.4.3. The re-mounting to the motor after autoclaving shall be done

according to Section 6.4.

Depending on the number of autoclaving or SIP cycles and the duration, distortion

effects in the plastics pump heads LPP-600.7/18 may lead to performance

reduction. It is therefore recommended to run the pump 10% below the maximum

speed after autoclaving or SIP.

Loading...

Loading...