5-2 LY Installation and Maintenance for LY 1001, LY 2001 and LY 3001 LMAIM1501

Table 5.1 – Torque Drive Nut Custom Bore and Keyway Sizes

Unit Type Maximum Bore Maximum Keyway

and Size inch (mm) inch (mm)

LY 1001 1¹₈ dia (28 dia) ¹₄ x ¹₈ (6 x 3)

LY 2001/3001 2³₈ dia (60 dia) ⁵₈ x ⁵₁₆ (15 x 7.5)

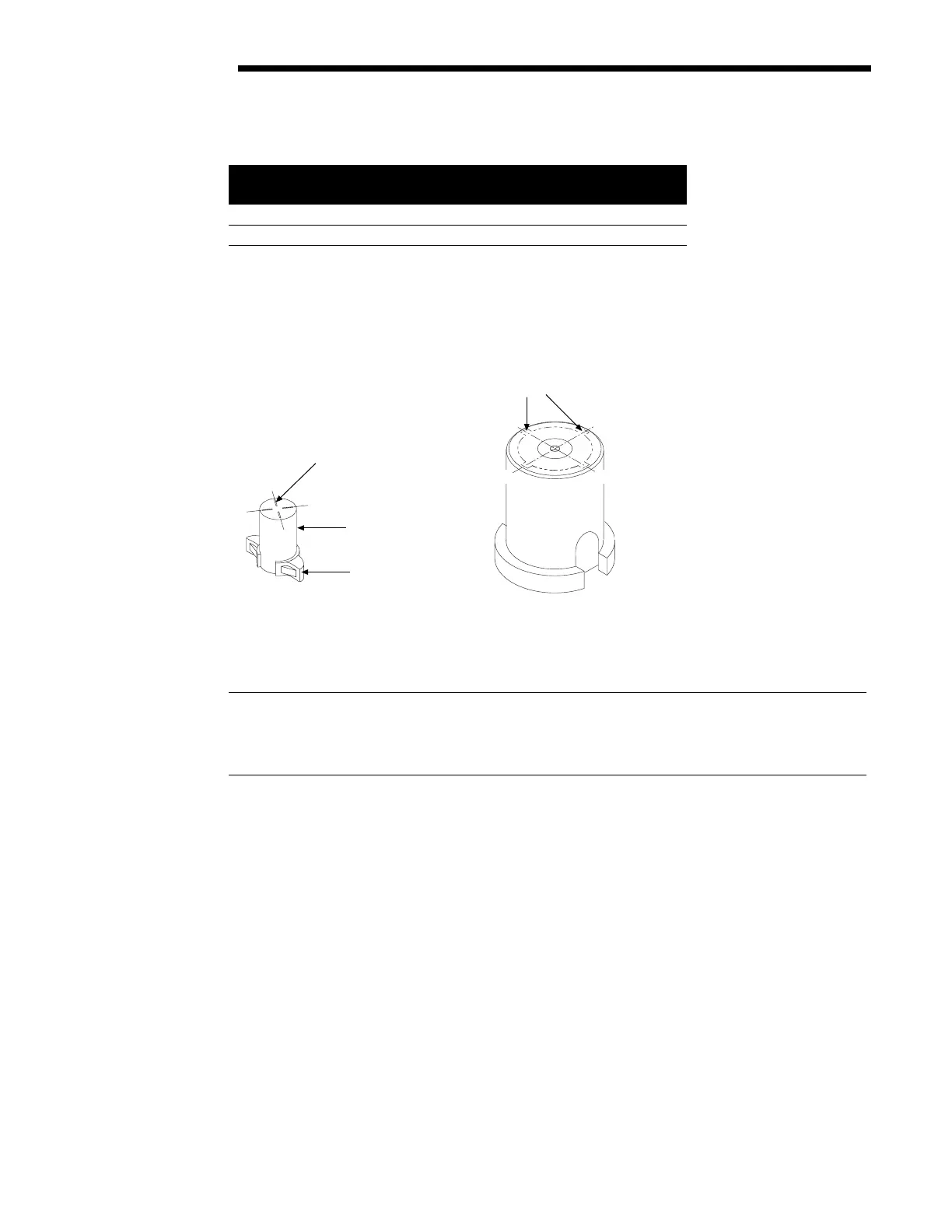

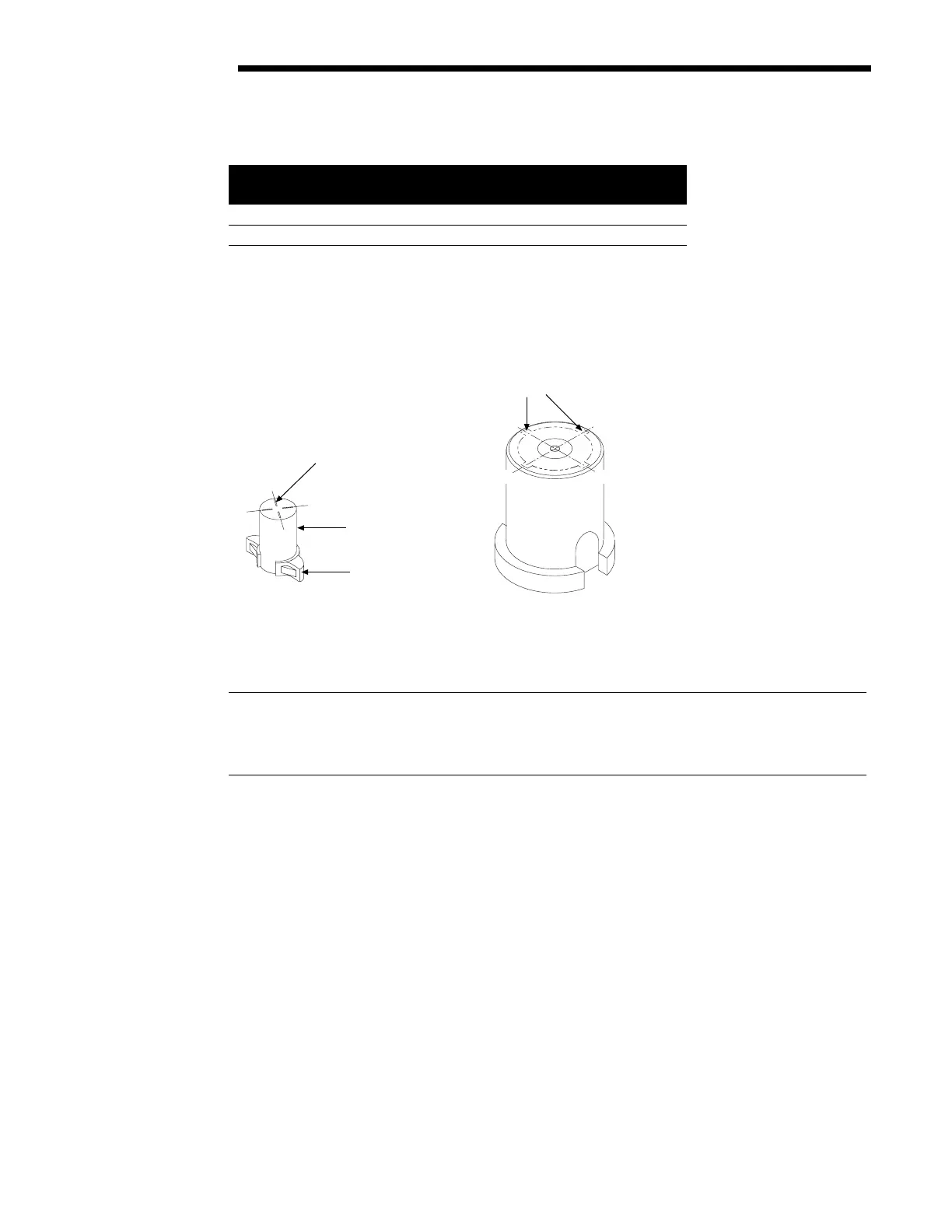

NOTE: Before keywaying, match the Torque Nut with the Valve Stem to ensure proper keyway location. Use the

Keyway Index Mark (LY 1001 only) for locating appropriate keyway location.

Figure 5.2 – LY Keyway Locations

5.3 Installation Overview

CAUTION: Be sure to complete each step of the installation overview before electrically operating your

actuator. If the actuator is already mounted to a valve from the manufacturer, verify that the actuator is

mounted according to the following overview. Failure to follow the installation procedures could result in

personal injury and/or improper operation and could cause damage to the equipment.

1. Mount Torque Nut (piece #32) in the actuator as shown in Figure 5.3 with the following alignment:

A. For LY 1001 – Stop Lugs facing the Actuator Mounting Adapter with index lines positioned to face the

Mechanical Stop Screws.

B. For LY 2001/3001 – Torque Nut axially aligned on the Drive Sleeve so that the bottom of the nut is

positioned inside the Actuator Mounting Base.

A

B

C

D

LY 1001 Keyway

Location Marks

D

A

B

C

Torque Nut

Stop Lug

LY 2001/3001 Keyway

Location Positions

Flow Control Division

Limitorque Actuation Systems

Loading...

Loading...