LMAIM1501 LY Installation and Maintenance for LY 1001, LY 2001 and LY 3001 5-5

Table 5.3 – Control Cover and Conduit Pipe Plug Hardware

Unit Type Control Cover Conduit Pipe Plug

Quantity Size Quantity Size

LY 1001 (WP & XP) 6 M8 x 40 mm 2 1” NPT Socket

Hex Head

LY 2001/3001 8 M12 x 50 mm (WP) 2 1” NPT Socket

M12 x 55 mm (XP) Hex Head

5. Adjust the Limit Switches, Mechanical Stops, and Position Indication Dial following the procedures detailed in

Section 5.6, Limit Switch and Mechanical Stop Settings.

6. Connect the wiring to the terminal strips provided on the actuator. Refer to the wiring diagram supplied with

the actuator. “Fork-type” terminal connections are recommended.

7. Insert a Conduit Pipe Plug in the unused conduit entrance if the wiring that enters the actuator uses only one

conduit entrance.

NOTE:

A. Explosionproof actuators require approved “sealing fittings” installed in accordance with the National

Electric Code.

B. Submersible actuators require an approved “sealing fitting” in order to keep water from entering the

actuator.

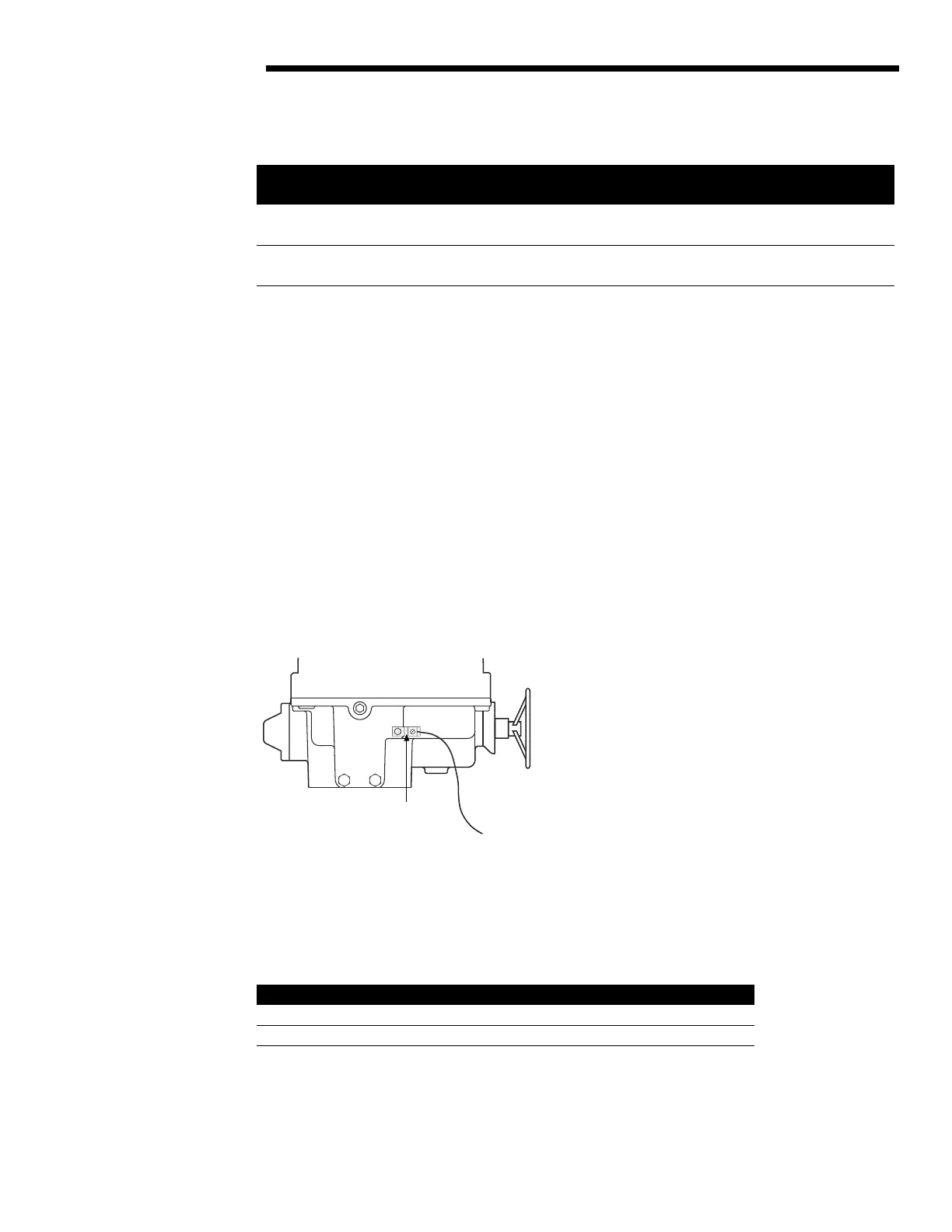

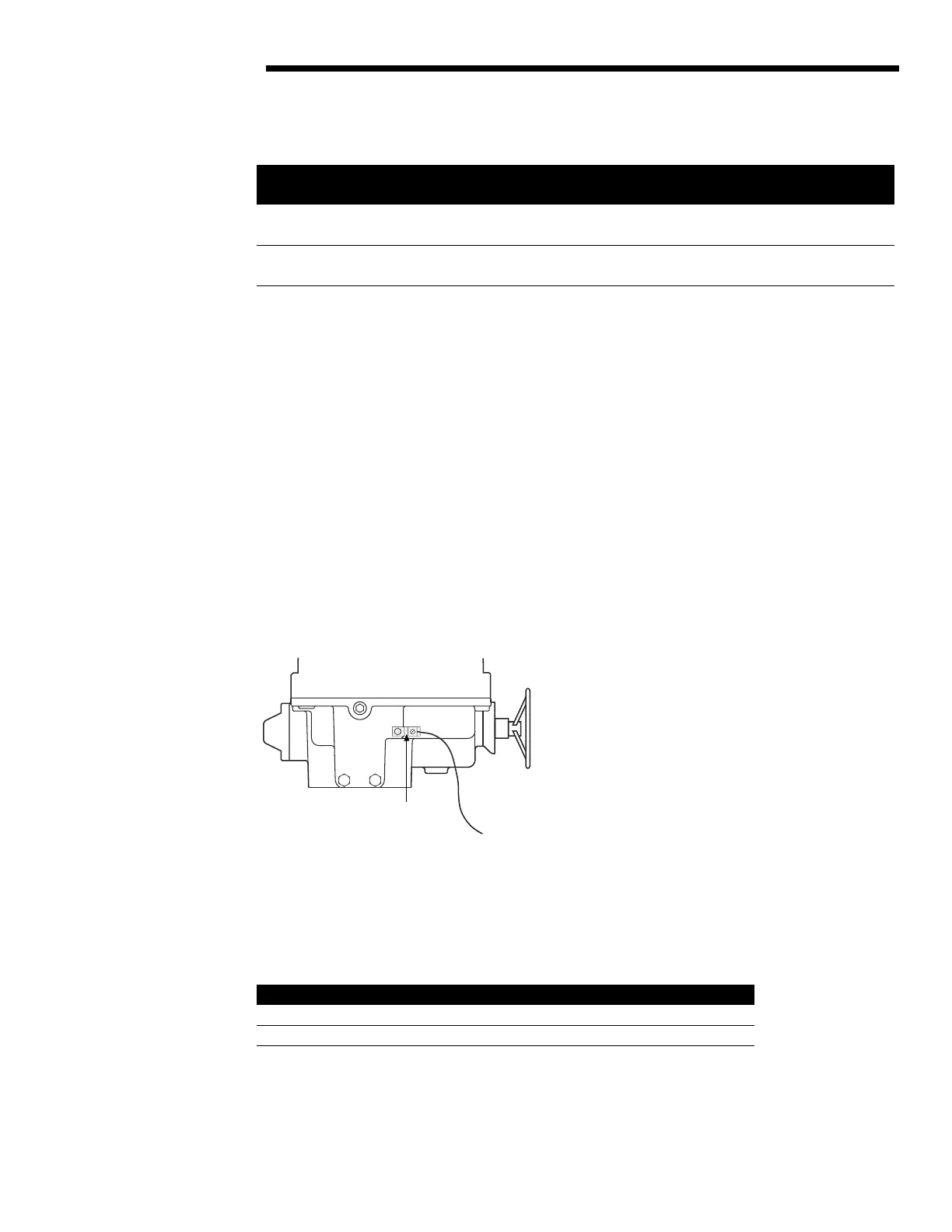

8. Attach grounding wire to Grounding Lug (piece #141).

9. Verify motor rotation direction to ensure that the limit switch is wired properly for intended operation. (See

Section 6.2, Verify Correct Motor Rotation (Phasing) and OPEN/CLOSE Pushbutton Operation.)

Figure 5.5 – Grounding Lug Location

10. Reinstall Control Cover (piece #3).

NOTE: Submersible actuators require tightening the Control Cover Bolts and Integral Control Cover Bolts to a

specified torque in order to maintain submersibility. (See Table 5.4 for specific torque settings.)

Table 5.4 – LY Control Cover and Integral Control Cover Bolt Sizes and Torques

Unit Type Control Cover Integral Compartment

LY 1001 M8 - 10 to 15 ft-lb M10 - 15 to 20 ft-lb

LY 2001/3001 M12 - 20 to 25 ft-lb M10 - 15 to 20 ft-lb

Unit is now ready for electrical operation.

#141 Grounding Lug

To earth ground

Flow Control Division

Limitorque Actuation Systems

Loading...

Loading...