5-6 LY Installation and Maintenance for LY 1001, LY 2001 and LY 3001 LMAIM1501

5.4 Torque Switch Settings

a DANGER: HAZARDOUS VOLTAGE. Turn power OFF before opening the Electrical Compartment Cover or

making any adjustments to the Torque Switch.

CAUTION: Installing or adjusting the Torque Switch with the actuator in a loaded condition will result in loss of

torque protection. Before adjusting or installing the Torque Switch, place the actuator in MANUAL mode and

turn the Handwheel in the direction necessary to release the torque load on the Wormshaft Assembly.

NOTE: Removal or modification of the Torque Switch Limiter Plate will void the actuator warranty. Do not exceed

the torque setting indicated by the Torque Switch Limiter Plate without contacting the Limitorque Service

Department.

The LY unit is equipped with a do W to MEDIUM or HIGH by adjusting the Torque Switch Adjustment Screw unless

it is limited by the Limiter Plate. (See Figure 5.6 for Torque Switch Adjustment Screw location.)

5.5 Rewiring the Torque Switch for Non-Standard Drive Sleeve Rotation

CAUTION: Double-check the wiring diagram to verify that the Torque Switch is wired appropriately for the appli-

cation. The Torque Switch will not protect the valve from over-torque if the Torque Switch is not wired properly

for the application.

LY series actuators are typically supplied with a CCW Drive Sleeve rotation to open a valve. The Torque Switch is

marked OPEN (CCW) and CLOSE (CW) based upon CW Drive Sleeve rotation to close the valve. The Mechanical

Dial Position Indicator (MDPI) is typically mounted for CW rotation to indicate the CLOSED position. If opposite

Drive Sleeve rotation is required (CCW to close a valve), the following Torque Switch modifications are required.

1. Turn all power to the actuator OFF.

2. Reverse the ID Limiter Plate.

3. Interchange OPEN Torque Switch wires 18 and 18C with CLOSED wires 17 and 17C. (Refer to the wiring

diagram for other Torque Switch wiring configurations.)

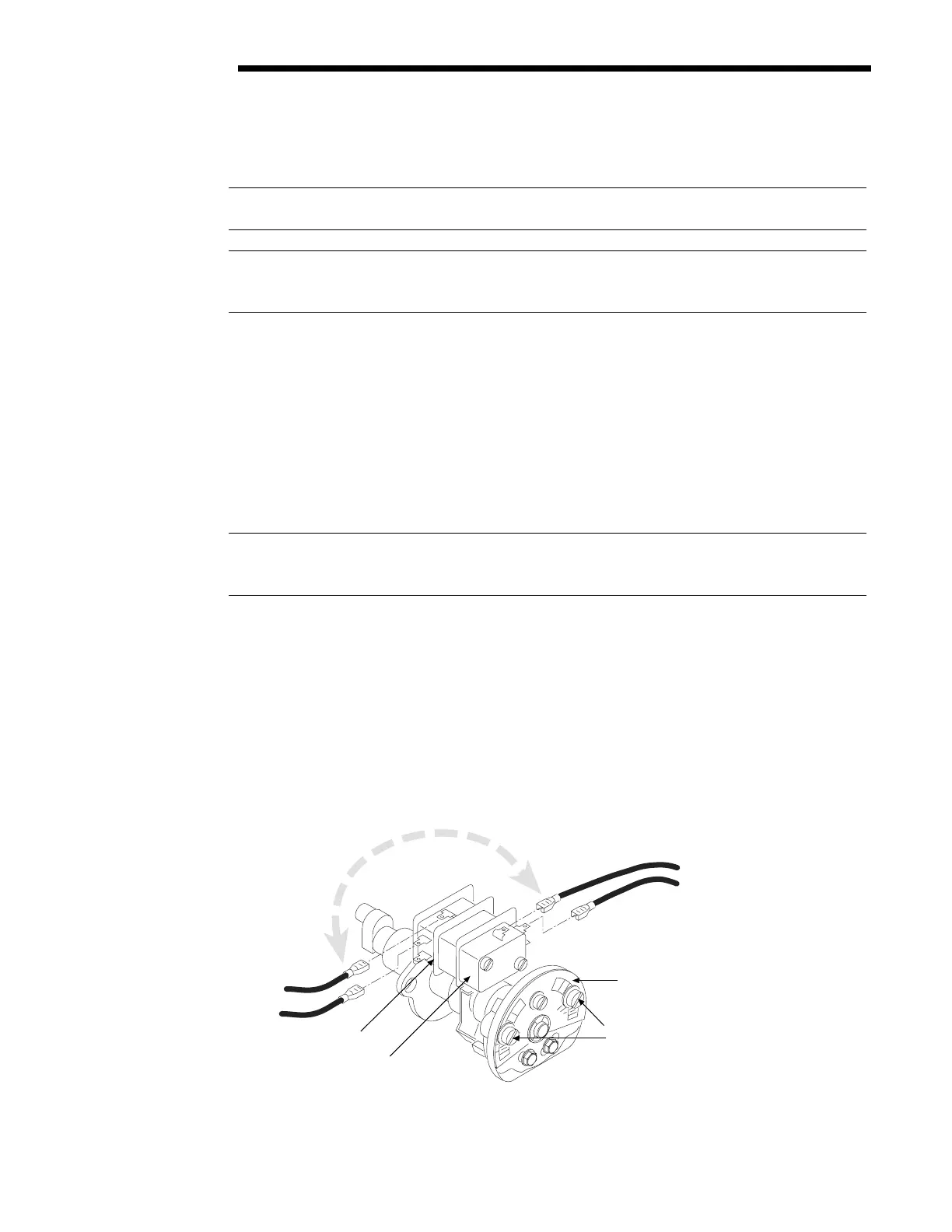

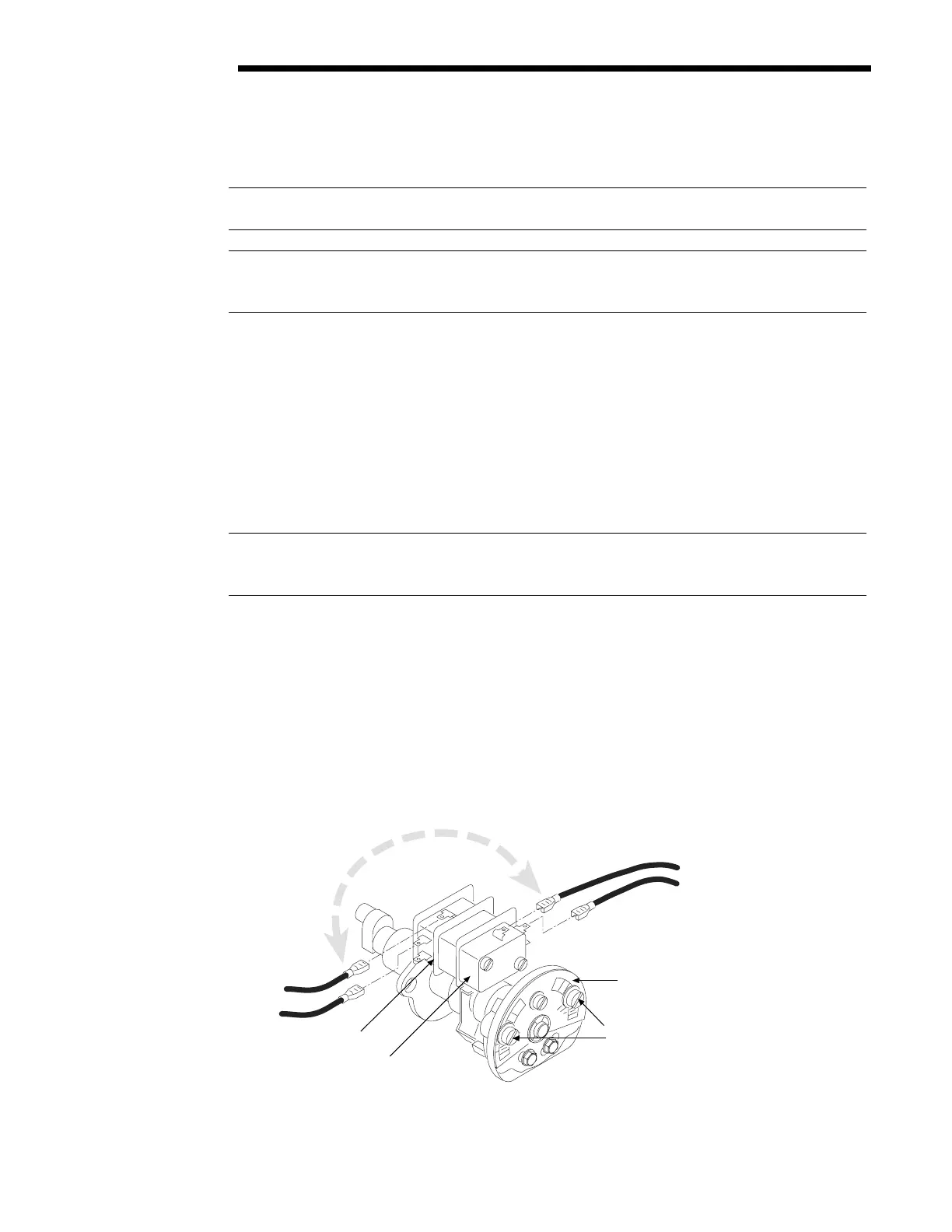

Figure 5.6 – Reversing Torque Switch Wiring

4. Remove the MDPI Plate and flip over for indication of CCW rotation to the valve’s closed position. (See Figure

5.12 for MDPI Dial Plate.)

L

Y

-

1

H

M

L

H

M

L

C

L

O

S

E

O

P

E

N

Typical CLOSE-circui t

microswitch (17 &17C)

Typical OPEN-circui t

microswitch (18 &18C)

ID-Limiter Plate

Torque Switch

Adjustment Screws

Flow Control Division

Limitorque Actuation Systems

Loading...

Loading...