LMAIM1501 LY Installation and Maintenance for LY 1001, LY 2001 and LY 3001 6-5

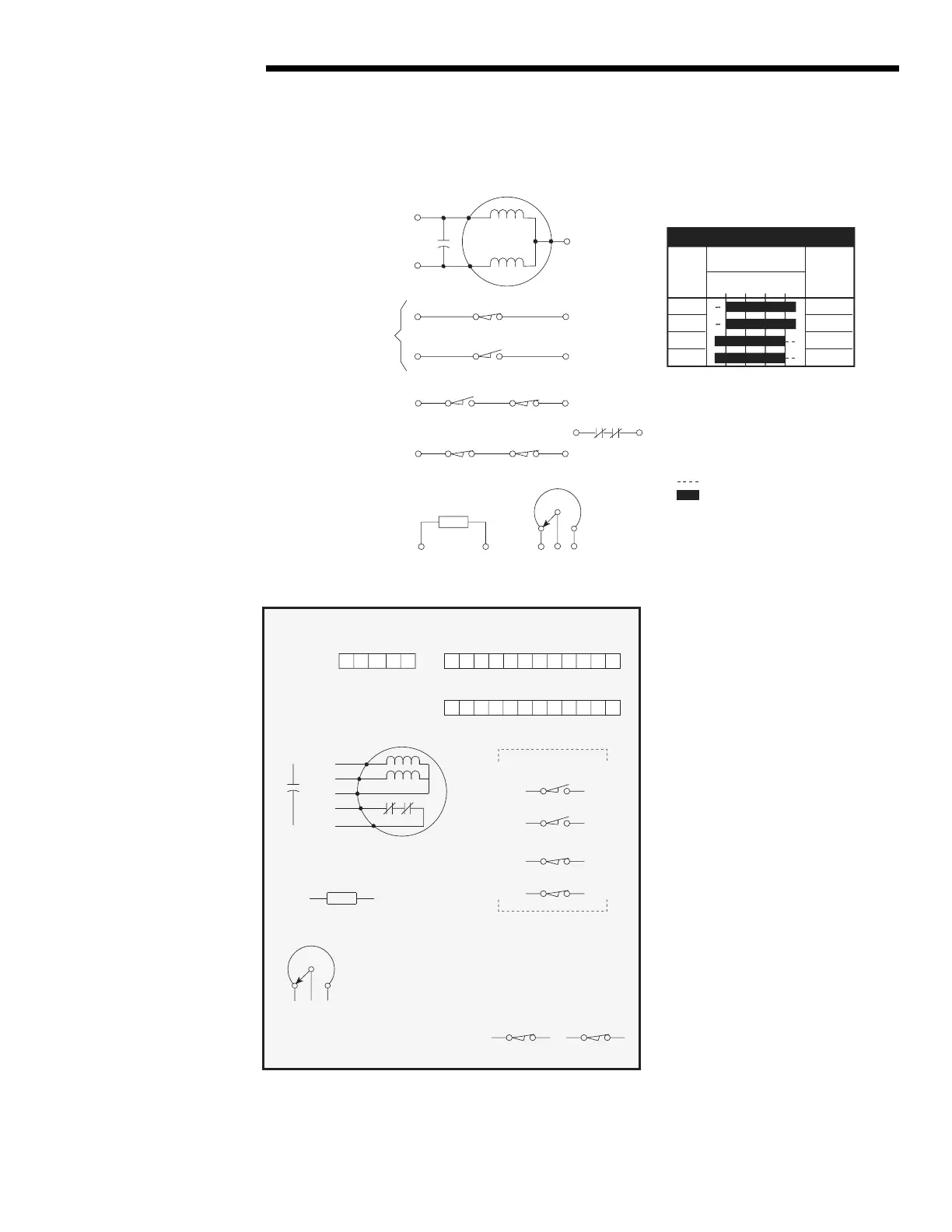

Figure 6.3 – Standard Actuator/Single-Phase

T2

T1

1 ph

MOTO R

T3

CAP

T2

T1

(P)

(P)

P3

P2

P1

5

9

5C

9C

17

18

17C

18C

8

4

INDICATION

TS18

TS17

LS5

LS9

LS8

LS4

CLOSE CIRCUIT

OPEN CIRCUIT

POT

(OPTIONAL)

L2

L1

HTR

LY COMPARTMENT

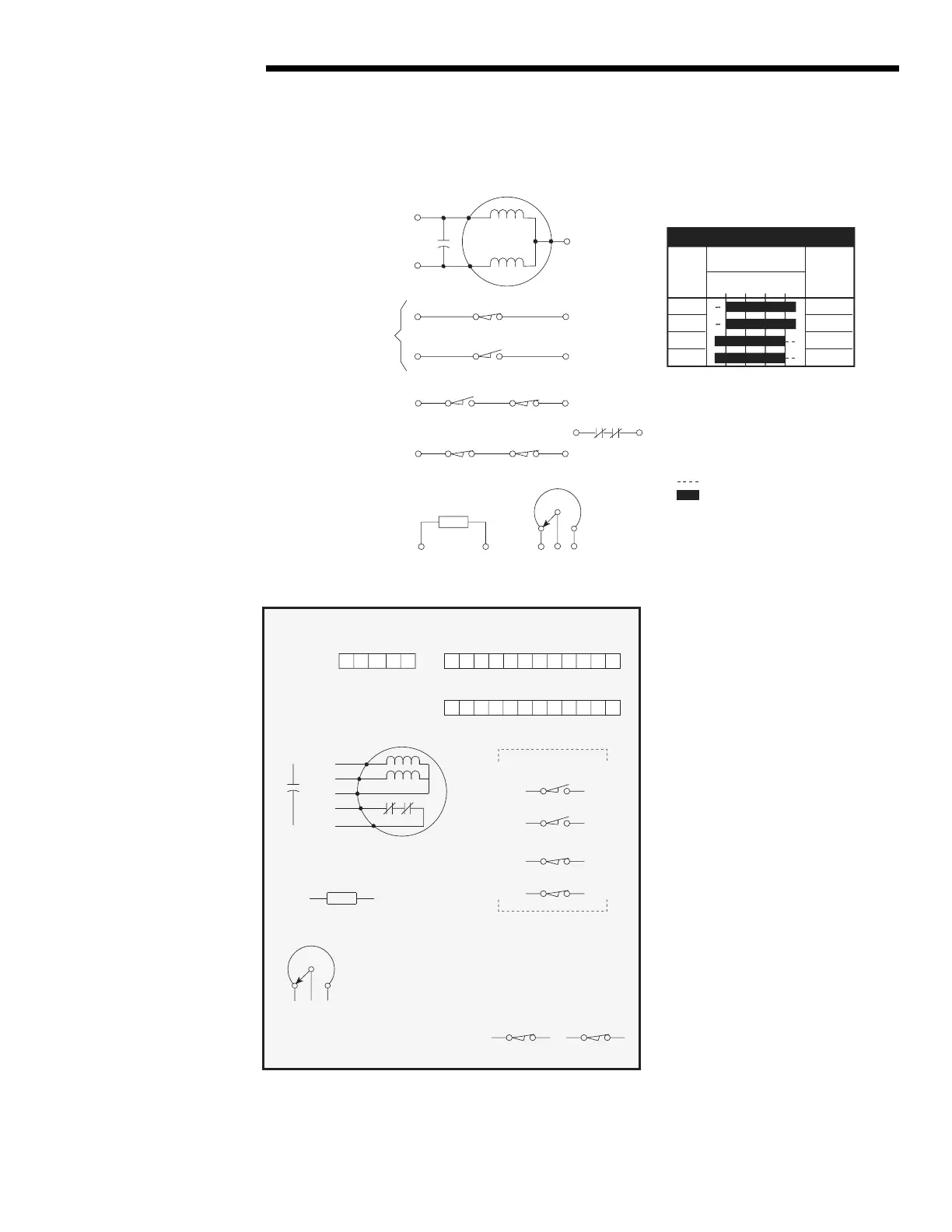

9

17C

9C

8

55C

18C4

TOP

BOTTOM

LS4

1ph

MOTOR

T1

T2

T2

T1

CAP.

LS8

LS5

LS9

TS17

17C 17

TS18

18C 18

L2L1

HTR

P1

P2

P3

CLOSE

OPEN

POT

(OPTIONAL)

TH.OL

T3

P3

9CL1 T2

17L2 8P2P1 9T1 T3

55C4CL2

22

CL2

22 CL2

TH.OL

LEGEND

HTR —Space heater (LY COMPT.)

POT —Slidewire transmitter (optional)

(See certification sheet if supplied)

TH. OL —Thermal overload (internal)

TS18 —Opening torque switch interrupts

control circuit if mechanical overload

occurs during opening cycle.

TS17 —Closing torque switch interrupts

control circuit if mechanical

overload

occurs during closing cycle.

NOTES

1. Open contact

2. Close contact

3. All limit switch trip points

are fully adjustable.

Limit Switch Contact Development

LIMIT

SWITCH

CONTACT

4

5

8

9

VALVE POSITION

FULL

OPEN

FULL

CLOSE

FUNCTION

OPEN LIMIT

INDICATION

CLOSED LIMIT

INDICATION

Valve shown in full open position

Note: Refer to certified data

for construction purposes

16-476-1630-2C.

22

18

Flow Control Division

Limitorque Actuation Systems

Loading...

Loading...